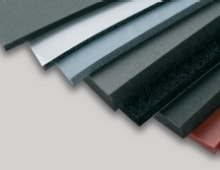

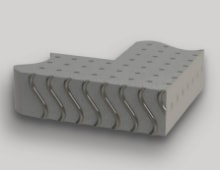

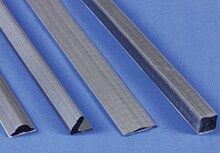

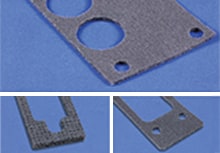

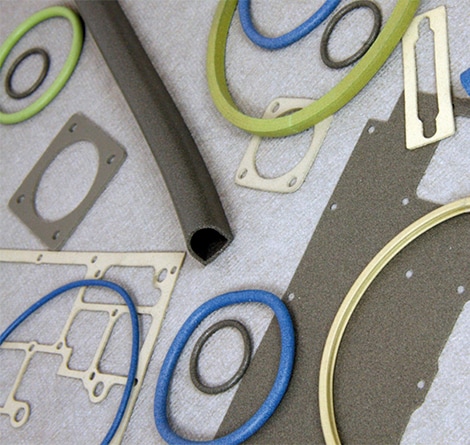

Our EMI shielding solutions offer various conductive fillers that are designed to ensure galvanic compatibility while providing low contact resistance between mating surfaces. Our conductive elastomers are fully cured silicones or fluorosilicone loaded with a variety of highly conductive particles providing superior EMI/RFI shielding performance combined with excellent environmental sealing.

Why is EMI shielding important?

All active electronic devices have the potential to emit electromagnetic radiation. EMI shielding products protect critical electronic components and systems from EMI interference.

- EMC compliance required by law/performance specifications

- EMC non-compliance causes system level redesign late in product development process

Where is EMI shielding used?

EMI shielding gaskets are applied at the seams of an enclosure to establish a low resistance conductive path to block radiated emissions into and out of the enclosure.

- Conductive gaskets/windows/vents at enclosure assembly level

- Conductive gaskets for module assembly

- Conductive gasket at board level cans at PCB level

EMI Shielding Application Solution (Guide)

RFI/EMI shielding gaskets and components provide exceptional EMC shielding solutions to address regulatory compliance and performance needs. Our shielding solutions include electrically conductive gaskets, EMI shielding ventilation panels, shielded window, cable shielding and shielding components.

Electromagnetic Interference Shielding Whitepaper

Electromagnetic interference (EMI), also known as radio frequency interference (RFI), results when an outside source causes noise or interference in an electrical path or circuit. Shielding is necessary to prevent EMI from causing electronic devices to malfunction.

Download NowEMI webinar

Electromagnetic Interference is a form of pollution that can affect electronic equipment that is not protected from it. Think of it as Electromagnetic smog. EMI can cause effects ranging from annoying noises on your car radio to serious accidents when safety critical equipment is caused to malfunction.

Watch Now