-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

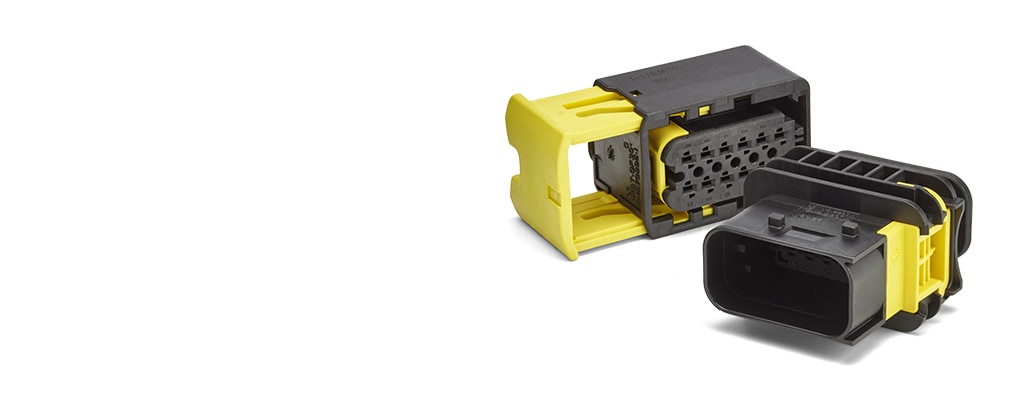

Heavy Duty Sealed Connector Series Housings

- AMP

- Heavy Duty Sealed Connector Series

Product Features

-

Connector System: Wire-to-Wire

-

Sealable: Yes

-

Connector & Contact Terminates To: Wire & Cable

-

Circuit Application: Power

-

Operating Temperature (Max)(°C): 140

Available from

Overview

Key Benefits

Heavy Duty Sealed Connector Series Housings

- Versatile Configurations: Accommodates a range of positions from 2 to 18 cavities, supporting varied wiring needs.

- High Current Capacity: Supports contact sizes that carry up to 40 amps, suitable for power-intensive applications.

- Flexible Mounting: Offers both in-line and flange mounting options for different installation scenarios.

- Durable Construction: Constructed from high-quality thermoplastic materials, providing resistance to mechanical and environmental stress.

- Wide Temperature Range: Operates effectively across a broad temperature spectrum, making it suitable for extreme conditions.

- Protection Against Elements: Rated IP67 and IP69K, providing resistance to dust and water ingress, suitable for harsh environments.

- Easy Identification: Multiple color options facilitate easy identification and organization of electrical connections.

- Accessory Compatibility: Compatible with a variety of accessories, enhancing functionality and ease of use.

- Secure Mating: Slide lock and integrated secondary lock mechanisms help maintain reliable electrical contact.

- Standards Compliance: Meets industry standards for flammability and ingress protection, supporting regulatory compliance in various applications.

Heavy Duty Sealed Connector Series Housings have a poka-yoke feature, L-shaped seal, and four keying options.

Key Features

Heavy Duty Sealed Connector Series Housings

| Feature | |

|---|---|

| Contact Size Compatibility |

Accepts contact sizes 6.3/4.8K (up to 40 amps), 2.8 (up to 40 amps), and 1.5K (up to 20 amps) for flexible application in power and signal circuits. |

| Cavity Arrangements | Available in 2, 3, 4, 6, 7, 8, 10, 12, 15, 16, and 18 cavity configurations to meet a range of wiring requirements. |

| Mounting Options | Supports both in-line and flange mount configurations for ease of installation in various setups. |

| Housing Material | Constructed from durable thermoplastic materials, providing resistance to mechanical and environmental stress. |

| Slide Lock for Mating |

Features a secure slide lock mechanism for stable and reliable connections. |

| Integrated Secondary Lock | Enables contact alignment and retention, enhancing connection reliability. |

| Temperature Range | Operates effectively within -40°C to 140°C (-40°F to 284°F). |

| Protection Rating | Meets IP67 and IP69K standards for protection against dust and water ingress. |

| Electrical Specifications |

Supports wire sizes from 6.00 to 0.20 mm² and operates effectively in a voltage range up to 60 VDC |

| Color and Keying Options |

Available in multiple colors and keying codes, facilitating easy identification and assembly. |

| Flammability Rating | Meets UL 94V-0 standards for flammability resistance. |

| Accessory Compatibility |

Compatible with accessories such as backshells, fixing slides, protection caps, blind plugs, and sealing plugs, enhancing versatility and protection. |

| Centerline (Pitch) | Provides a range of centerline options from 2.5 mm to 9.5 mm to accommodate different wire sizes. |

| Operating Voltage | Suitable for nominal voltage architectures of 12V, 24V, 32V, 42V, and 60V. |

| Mating Alignment | Keyed for precise alignment during mating. |

| Strain Relief | Options available for added strain relief or without for flexible installations. |

| Connector Position Assurance | Some configurations support Connector Position Assurance (CPA) for added security during connection. |

| CAN Bus Compliance | Meets CAN (Controller Area Network) Bus protocol specifications according to SAE (Society of Automotive Engineers) J1939 standard, supporting modern vehicle communication systems. |

Real World Applications

Heavy Duty Sealed Connector Series Housings

- Automotive: Used in cars, trucks, and buses to protect and connect electrical systems, supporting reliable operation under varying conditions.

- Construction Equipment: Provides secure connections for heavy machinery, helping maintain functionality in environments with dust and debris.

- Agriculture: Connects electrical components in farming equipment, supporting performance in outdoor and variable weather conditions.

- Marine: Protects electrical connections in boats and marine vehicles from moisture and saltwater exposure.

- Mining: Used in mining machinery to safeguard electrical systems against dust and harsh environmental conditions.

- Emergency Vehicles: Secures electrical systems in ambulances, fire trucks, and other emergency vehicles, supporting critical operations in demanding environments.

- Forestry: Applied in forestry machinery to maintain electrical connections exposed to dirt, moisture, and mechanical stress.

- Recreational Vehicles: Used in ATVs, motorcycles, and other recreational vehicles to provide reliable electrical connections across diverse terrains and conditions.

Learn about our rugged Heavy Duty Sealed Connector Series for harsh environment applications. Watch this video for an overview of the connectors and for step-by-step instructions on inserting and removing contacts, as well as mating and unmating.

FAQ

Heavy Duty Sealed Connector Series Housings

Q: When should I use the Heavy Duty Sealed Connector Series?

A: Heavy Duty Sealed Connector Series provides reliability and performance on the engine or transmission, under the hood, for motor controllers, solenoid interfaces, on the chassis, or in the cab. It offers field-proven reliability and rugged quality. Rectangular, thermoplastic housings offer a wide operating temperature range, and silicone rear wire and interface seals allow the connectors to withstand conditions of extreme temperature and moisture. The connectors feature an integrated slide lock for mating and an integrated secondary locking device for contact alignment and retention.

Q: Whatis the vibration rating for the Heavy Duty Sealed Connector Series?

A: No physical damage of housings and contacts, no derogation of function; the connection may not open at 177 m/s2, 94 hours for each of the three axes. See product specification 108-94020 for full specifications.

Q: What is the flammability rating for the Heavy Duty Sealed Connector Series?

A: Product with a UL 94 V0 rated material is available.

Features

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Connector Shape Rectangular

-

Connector System Wire-to-Wire

-

Connector & Housing Type Housing for Female Terminals, Housing for Male Terminals

-

Sealable Yes

-

Connector & Contact Terminates To Wire & Cable

-

Primary Locking Feature Integrated in Housing, On the Terminal

-

Mixed & Hybrid Connector No, Yes

Configuration Features

-

Number of Positions 2, 3, 4, 6, 7, 8, 10, 12, 13, 15, 16, 18

-

Number of Rows 1, 2

-

Blank Cavity Position 0, 2

Electrical Characteristics

-

Operating Voltage (VAC) 42

-

Operating Voltage (VDC) 42, 60

-

Nominal Voltage Architecture (V) 32, 42, 60

Body Features

-

Cable Exit Angle 180°, 90°

-

Primary Product Color Black, Blue, Gray, Green, Red, Violet

-

Connector & Keying Code A, A-B-C, B, C, D, E, F

Contact Features

-

Contact Type Receptacle, Tab

-

Contact Size 1.2mm, 1.5K, 1.5mm, 1.6mm, 2.8mm, 4.8K, 5.8mm, 6.3K, 6.3mm

-

Mating Tab Width (mm) 1.2, 1.5, 1.6, 2.8, 5.8, 6.3

-

Mating Tab Width (in) .047, .059, .06, .062, .063, .11, .22, .228, .248, .25

-

Contact Current Rating (Max) (A) 10, 16, 20, 23, 30, 32, 40, 50

Mechanical Attachment

-

Mating Alignment With

-

Mating Alignment Type Keyed

-

Strain Relief Add By Accessory, Without

-

Connector Mounting Type Cable Mount (Free-Hanging)

-

Terminal Position Assurance No, Yes

Housing Features

-

Housing Material PBT GF, PBT GF30

-

Centerline (Pitch) (mm) 2.5, 4, 5, 6, 9

-

Centerline (Pitch) (in) .098, .157, .196, .236, .24, .354

Dimensions

-

Wire Size (mm²) 1.5 – 6

-

Wire Size (AWG) 16 – 10

-

Row-to-Row Spacing (mm) 1.5, 12, 13.55, 2, 2.54, 3, 5.5, 5.6, 6, 6.2, 6.3, 6.45, 6.5, 6.8, 6.9, 7.25, 7.5, 7.55, 7.6, 7.7, 7.9, 8.6, 9, 9.5

-

Row-to-Row Spacing (in) .059, .079, .1, .118, .217, .22, .236, .24, .244, .248, .254, .256, .268, .272, .285, .295, .297, .299, .303, .311, .339, .354, .374, .472, .533

-

Product Length (mm) 25.7, 25.9, 27.6, 29.1, 32.6, 36, 37.5, 40.6, 42.5, 43, 44, 50.5, 52.6, 54.1, 62.5, 67.2

-

Product Length (in) 1.02, 1.08, 1.087, 1.146, 1.283, 1.417, 1.476, 1.598, 1.673, 1.693, 1.732, 1.988, 2.071, 2.13, 2.46, 2.461, 2.645, 2.646

-

Product Width (mm) 18.5, 25.7, 27, 31.25, 39.8, 42.4, 47.05, 47.1, 48.1, 50.6

-

Product Width (in) .728, 1.01, 1.011, 1.012, 1.063, 1.56, 1.567, 1.67, 1.852, 1.854, 1.89, 1.894, 1.992

-

Connector Height (mm) 19, 27, 29.8, 30.75, 31.2, 31.25, 39.8, 46.7, 47.05, 47.1, 48.1, 50.6, 53.1, 67.2

-

Connector Height (in) .748, 1.062, 1.063, 1.173, 1.211, 1.23, 1.567, 1.839, 1.852, 1.854, 1.894, 1.99, 1.992, 2.09

Usage Conditions

-

Operating Temperature (Max) 140 °C [ 284 °F ]

-

Operating Temperature Range (°C) -40 – 140

-

Operating Temperature Range (°F) -40 – 140, -40 – 284

Operation/Application

-

Circuit Application Power

Industry Standards

-

UL Flammability Rating UL 94V-0

-

Compatible With Agency/Standards Products DIN IEC 512

-

Degree of Protection IP67, IP69K, IP6K7

Packaging Features

-

Packaging Method Box, Carton, Package

-

Packaging Quantity 1, 72, 140, 150, 200, 210, 220, 230, 250, 280, 300, 320, 380, 396, 400, 450, 600, 700

Other

-

Connector Position Assurance Capable No

-

Serviceable No, Yes

Reference Number

-

TE Internal Number CAT-H3399-CH8172

Related Materials

Catalog

- Heavy Duty Sealed Connector Series (English) Heavy Duty Sealed Connector Series is designed to meet the rigorous demands of the commercial vehicle industry and off-road applications that require the highest standards of performance.

Product Specifications

- Heavy Duty Sealed Connector Series Specifications (English) This specification covers performance tests and quality requirements for Heavy Duty Sealed Connector Series.

Application Specifications

- Heavy Duty Sealed Connector Series Application Specifications (English) This specification covers the requirements for the application of the Heavy Duty Sealed Connector Series.

Connector Selector

- Connector Selector (English) The Connector Selector is a reference guide to TE Connectivity's (TE) Industrial & Commercial Transportation electrical connectors.

Flipbook Catalog

- Industrial & Commercial Transportation - Terminals and Connectors (English) TE's Industrial & Commercial Transportation Terminals and Connectors flipbook catalog features AMPSEAL, AMPSEAL 16, Circular DIN, DEUTSCH, Heavy Duty Sealed Connector Series, LEAVYSEAL, and Superseal 1.0 connectors, contacts, tools, and accessories.

Are you sure you want to close chat?

Chat

To begin your chat with TE please enter your details