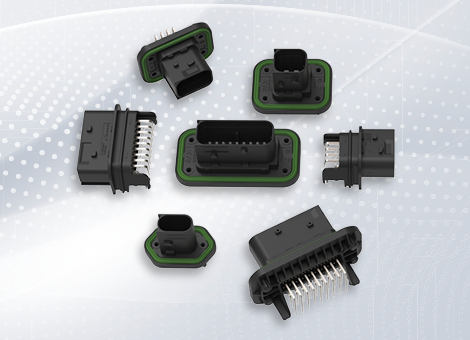

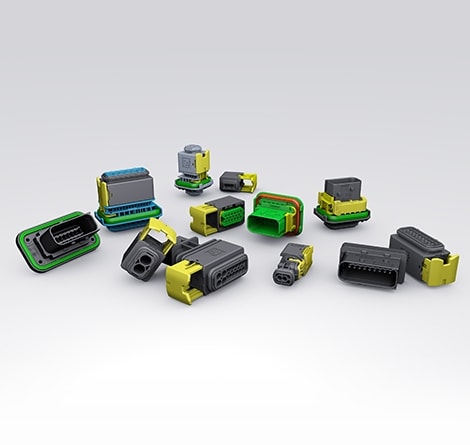

Sealed connections built for harsh vehicle duty

Keep power and signals moving in harsh environments. Our Heavy Duty Sealed Connector Series help protect circuits against dust, water, and vibration in trucks, buses, construction, and agriculture equipment. With rugged, UL94 V0 housings, an integrated secondary lock, and IP67 sealing (IP6K9K with backshell), they fit inline, flange mount, or PCB designs - 2 to 18 positions - so you can build compact, serviceable harnesses that last.

New Product Features

Heavy Duty Sealed Connector Series

- Fits tight PCB layouts: right-angle (90°) and straight (180°) versions help you route power and signal cleanly inside a pcb application.

- Simplifies assembly: integrated coding (A/B) and key groups (A–E) help reduce mismating during build and service.

- Scales with your design: 4, 8, 12, and 18 positions cover low to higher pincount needs across Contro Units.

- Works with the series family: compatible with series backshells, protection caps, fixing slides, and sealing/cavity plugs at the system level.

- Built for harsh environment: the series supports IP67 and IP6K9K (with cover and counterpart) and vibration tested performance when used as a mated system.

Key Benefits:

Heavy Duty Sealed Connector Series

- Lower applied cost with a shared contact family - works with AMP MCP 1.5K, 2.8, 6.3/4.8K and MCON 1.2 to cover many use cases, including high‑current paths up to 40 A on larger terminals.

- Protects against dust, water, and high‑pressure spray - IP67 sealing with options up to IP69K in supported configurations for harsh cleaning and overspray.

- Easier service and maintenance - individual wire seals crimp at the terminal base to simplify contact insertion and extraction.

- Assembly confidence - integrated secondary lock and mistake‑proof (poka‑yoke) design help verify each terminal’s position during assembly.

- Design flexibility - inline, flange‑mount, or PCB options; wire‑to‑wire, wire‑to‑device, or wire‑to‑board; six housing sizes; up to six keying options; 2–18 positions.

- Complete system approach - accessories such as backshells, protection caps, cavity plugs, and fixing slides help tune sealing and strain relief.

- Supports vehicle networking - dedicated housings and components are available for CAN bus architectures (including Y‑connector and 120 Ω resistor options).

Key Applications

As they are sealed and robust these connectors are serving multiple applications in your industrial and commercial vehicles.

Real-world Applications:

Heavy Duty Sealed Connector Series

Trucks & Buses (On Highway)

- Chassis harnessing: junctions and splices along frame rails; lighting, markers, beacons, work lamps; liftgate and tail lift controls. Heavy duty sealed connectors help resist road spray and debris; slide lock and secondary lock support fast service.

- Braking & stability systems (ABS/EBS): wheel speed sensors, modulator valves, brake control units near exposed wheel ends. IP67 sealing (IP6K9K with backshell) helps during washdowns; vibration testing supports duty cycles.

- Body & HVAC controls: blower motors, door actuators, wiper/washer pumps, step and ramp drives. Multiple cavity counts (2–18) let you combine power and signal with shared AMP MCP/MCON contacts.

- Telematics & diagnostics: telematics control units, GPS/RTK modules, remote diagnostics gateways. CAN bus accessories (Y connector and 120 Ω resistor) support SAE J1939 nodes and service terminators.

Construction Equipment (Off Highway)

- Hydraulics & actuation: spool valve coils, proportional valve drivers, pump controllers, auxiliary circuits on booms and arms. Sealed housings and backshell options help in mud, slurry, and high pressure cleaning.

- Powertrain modules: engine ECUs, transmission controllers, fan drives, after-treatment dosing units. Temperature range (–40 °C to +140 °C) and robust locks support engine bay locations.

- Operator station & safety: seat and boom interlocks, parking brake status, beacon controls. Keyed housings reduce mismating during field service.

Agriculture (Off Highway)

- Implements & attachments: seeders, planters, sprayers, balers, header lifts, and hitch control modules. IP rated sealing helps against fertilizer, dust, and washdowns; multiple positions cover sensor clusters.

- Sensors & controls: fuel level, moisture, pressure, and position sensors; rate controllers on implement frames. Individual wire seals crimp at the terminal base for tidy routing and easier replacement.

Specialty & Municipal Vehicles

- Refuse, street sweepers, snow & ice, fire support: body control modules, spreader controllers, water pump and broom drives. Rugged housings and slide locks suit frequent service intervals and exposure to brine and detergents.

- Aerial & utility fleets: outriggers, PTO, winch and crane controls, stabilizer sensors. Options from 2 to 18 positions let one connector family support low count sensors and higher count I/O blocks.

Power Distribution & Electrical Centers

- PDMs and fuse/relay boxes: low voltage harness entries and serviceable covers. Up to 40 A per contact (contact dependent) supports mixed power/signal in one platform; accessory ecosystem (caps, sealing plugs, fixing slides) supports serviceability.

Key Industries

Our Heavy Duty Sealed Connector Series is used in multiple industries thanks to its robustness and ease of installation.

Truck

Bus

Construction Equipment

Agricultural Equipment

Special Vehicle

Automotive

Key Features:

Heavy Duty Sealed Connector Series

| Features | Details |

|---|---|

| Environmental sealing |

IP67; IP6K9K with cover/backshell (tab housings, per mounting guidance). |

| Current per contact |

Up to 40 A (contact‑dependent). |

| Positions | 2–18 positions (multiple cavity arrangements). |

| Mounting styles |

Inline, flange, or PCB mount (wire to wire, wire to device, wire to board). |

| Locking & service |

Integrated secondary lock; slide lock for mating; individual wire seals. |

| Materials | Glass filled PBT housings; UL94 V 0 option. |

| Temperature range |

-40°C to +140°C (operating). |

| Vibration | Tested at 177 m/s² for 94 h per axis (random vibration). |

| Contacts | AMP MCP 1.5K / 2.8 / 6.3/4.8K and MCON 1.2. |

| Accessories | Backshells, protection caps, cavity plugs, fixing slides. |

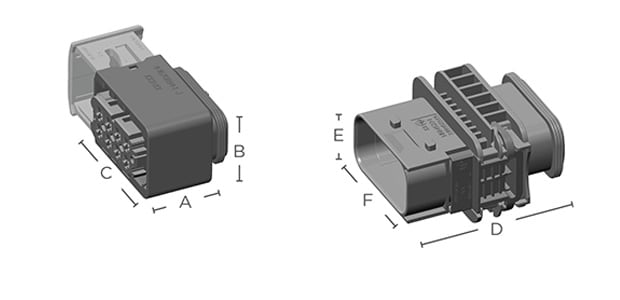

Heavy Duty Sealed Connector Series Dimensions

| Group | Receptacle Housing | Tab Housing | ||||

|---|---|---|---|---|---|---|

| Overall Length A | Overall Height B | Overall Width C | Overall Length D | Overall Height E | Overall Width F | |

| A | 1.23 (31.3) | 0.73 (18.5) | 1.02 (26.0) | 1.64 (47.1) | 0.75 (19.0) | 1.09 (27.6) |

| B | 1.23 (31.3) | 1.01 (25.7) | 1.19 (30.2) | 1.64 (47.1) | 1.06 (27.0) | 1.09 (27.6) |

| C | 1.23 (31.3) | 1.01 (25.7) | 1.23 (31.2) | 1.64 (47.1) | 1.06 (27.0) | 1.28 (32.6) |

| D | 1.23 (31.3) | 1.01 (25.7) | 1.54 (39.2) | 1.64 (47.1) | 1.06 (27.0) | 1.60 (40.6) |

| E | 1.23 (31.3) | 1.01 (25.7) | 2.02 (51.2) | 1.64 (47.1) | 1.06 (27.0) | 2.07 (52.6) |

Frequently Asked Questions - FAQ

Heavy Duty Sealed Connector Series

Q: What sealing performance do these heavy duty sealed connectors provide?

A: They are rated to IP67; when used with a backshell on flanged tab housings and installed per instructions, they reach IP6K9K. This helps protect against water, dust, and high pressure spray.

Q: Which contacts and currents are supported?

A: The series accepts AMP MCP 6.3/4.8K (up to 40 A), AMP MCP 2.8 (up to 40 A), AMP MCP 1.5K (up to 20 A), and MCON 1.2 contact families, giving flexibility for power and signal in one platform.

Q: Do you offer options for CAN bus networks?

A: Yes. There are dedicated CAN bus Y connectors and 120 Ω terminators that meet SAE J1939, fully compatible with the series accessories and parts.

Glossary

Heavy Duty Sealed Connector Series

IP67: Dust tight and protected against temporary immersion in water when mated and installed as specified. Series page states IP67 at the system level.

IP6K9K (ISO 20653): Dust tight (6K) plus resistance to high pressure, high temperature spray (9K) used in vehicle washdowns. Applied here at the mated system (with cover/backshell on flanged tab housings).

Secondary lock (TPA): A built in device that helps confirm terminals are fully seated before mating.

Slide lock: A latch that helps draw the two halves together for a positive mate.

Backshell: A rear housing that helps with cable strain relief and routing; required for the higher IP rating listed on the series page.

Cavity & sealing plugs: Parts used to close unused cavities so the environmental seal is maintained.

Keying / coding (A/B) & groups (A–E): Mechanical features that allow only the intended plug and header/housing to mate, reducing errors.

Tab size (1.2 mm; 1.6 × 0.6 mm): Blade dimensions on PCB headers that match the designated female terminals.

Wire to board header: A PCB mounted interface that lets the sealed connector family pass through an ECU wall to the board.

CAN bus / SAE J1939: A common vehicle network; the series has Y connector and 120 Ω terminator options for these nodes.

| Contact family |

Typical use |

Current guidance* |

Wire sizes supported (series) |

Crimp & tools (category) |

Notes |

|---|---|---|---|---|---|

| AMP MCP 6.3/4.8K |

Higher‑current power circuits |

Up to 40 A | 0.20–6.00 mm² (series feature) | Stamped‑and‑formed crimp; manual hand tools and applicator‑based tooling (per Application Specifications) |

Used across many power devices. |

| AMP MCP 2.8 |

Power / mid‑current I/O |

Up to 40 A | 0.20–6.00 mm² | Hand crimpers; bench/applicator tooling | Common in engine/chassis harnesses. |

| AMP MCP 1.5K |

Low‑ to mid‑current |

Up to 20 A | 0.20–6.00 mm² | Hand crimpers; bench/applicator tooling | Smaller .circuits; compact packaging. |

| MCON 1.2 |

Low‑level signals |

(signal‑class) | 0.20–6.00 mm² | Hand crimpers; bench/applicator tooling | For sensor signals and network lines. |

* Current values and wire‑size span are taken from the live series page and apply by contact family; verify exact limits in the linked Product and Application Specifications before release to production.