-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples (with Business email address)

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

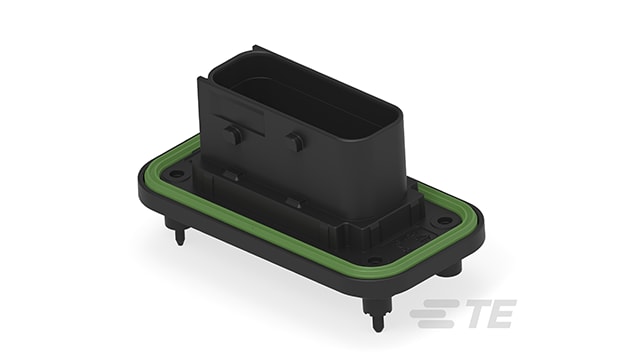

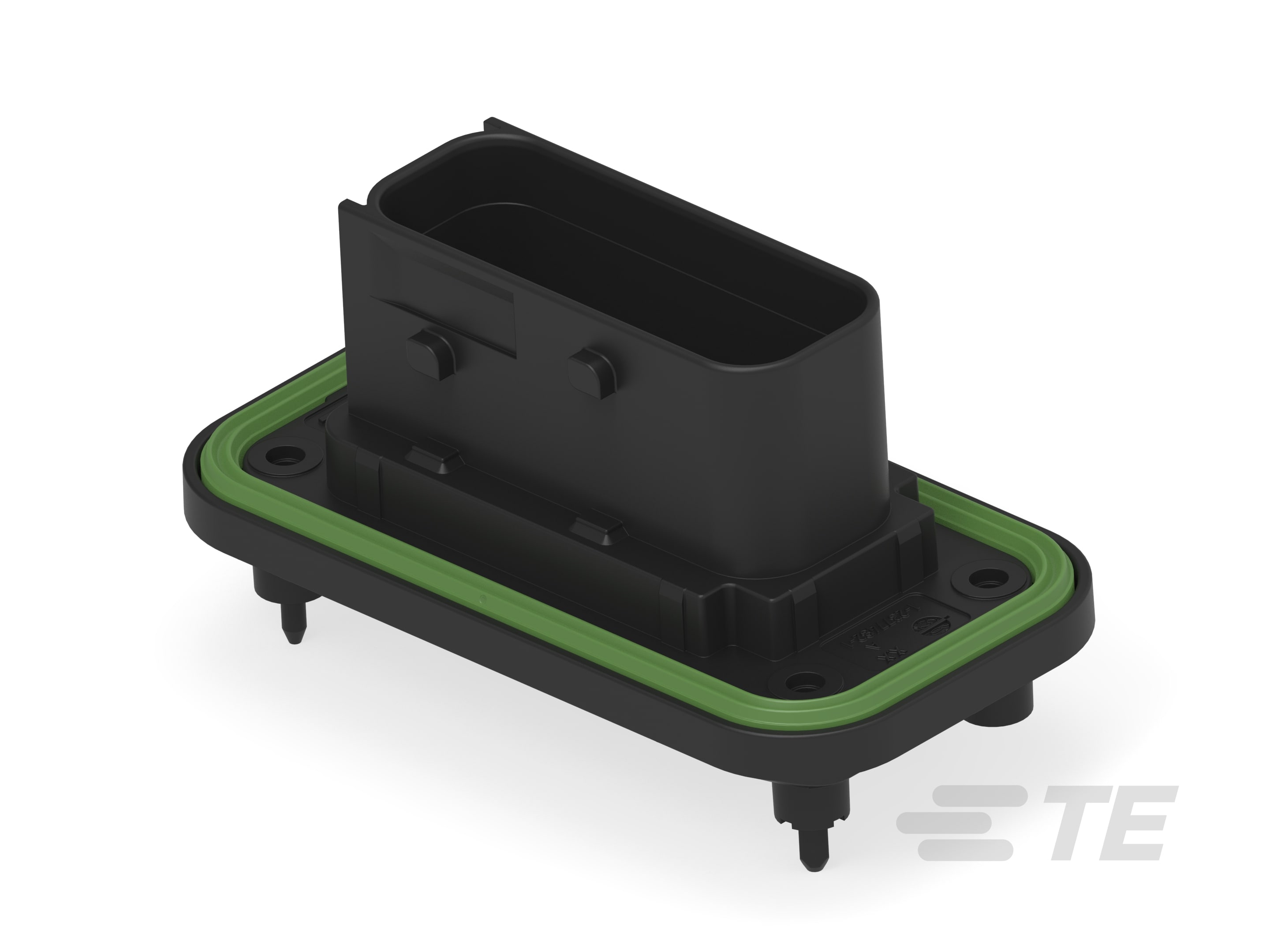

Heavy Duty Sealed Connector Headers

Product Features

-

PCB Mount Orientation : Horizontal | Right Angle | Vertical

-

Contact Current Rating (Max) (A): 10 | 16 | 20

-

Termination Method to PCB : Through Hole - Solder

-

Sealable : Yes

-

Centerline (Pitch) (mm): 2.5 | 4 | 6

-

Centerline (Pitch) (in): .098 | .157 | .236 | .24

Available from

When space is tight and uptime matters, Heavy Duty Sealed Connector Headers give your ECUs a secure, sealed wire to board connection that holds up to vibration, dust, and washdowns in industrial and commercial vehicles.

These new headers are part of our Heavy Duty Sealed Connector Series. They mount to the PCB (through hole) and pair with proven AMP MCP and MCON contact systems to carry power and signal in off highway machines, trucks, and buses. Designs include integrated secondary locks that help confirm terminal position during assembly.

Choose 4 mm or 6 mm centerline options and position counts from 2 to 18 to match your architecture. With operating range from -40°C to 140°C (-40°F to 284°F) and IP67 sealing (up to IP69K with cover on flanged tab housings), the Heavy Duty Sealed Connector Series help protect connections in pressure wash and high vibration zones. Select the contact size your circuit needs - up to 40 A per contact with AMP MCP 6.3/4.8K - while keeping harness service simple in the field.

New Rugged PCB Headers for Heavy-duty Vehicles

Heavy Duty Sealed Connector Headers

New Heavy Duty Sealed Connector Series PCB Headers - 180° and 90°

Extend your ECU layout options with new Heavy Duty Sealed Connector Headers in vertical (180°) and right angle (90°) configurations. Keep heavy duty sealed connector series sealing, secondary locks, and mixed cavity layouts while meeting tighter packaging targets in die cast enclosures.

- 180° and 90° orientations for compact ECU designs

- Mixed cavities and position counts from 4, 8, 12 and 18

- Works with AMP MCP and MCON families used across Heavy Duty Sealed Connector Series harnesses

- Accessories: backshells, fixing slides, protection caps, sealing plugs

- Optimized for use in aluminium die-cast ECU housings

- Glued and flanged header concepts to support sealing and mechanical strength

Learn how our new PCB headers support sealed ECU designs with right-angle and straight configurations. See how they simplify assembly and enhance wire-to-board performance in harsh environments.

Key Benefits

Heavy Duty Sealed Connector Headers

- Lower applied cost with a shared contact family: works with AMP MCP 1.5K, 2.8, 6.3/4.8K and MCON 1.2 to cover many use cases, including high‑current paths up to 40 A on larger terminals.

- Protects against dust, water, and high‑pressure spray: IP67 sealing with options up to IP69K in supported configurations for harsh cleaning and overspray.

- Easier service and maintenance: individual wire seals crimp at the terminal base to simplify contact insertion and extraction.

- Assembly confidence: integrated secondary lock and mistake‑proof (poka‑yoke) design help verify each terminal’s position during assembly.

- Design flexibility: inline, flange‑mount, or PCB options; wire‑to‑wire, wire‑to‑device, or wire‑to‑board; six housing sizes; up to six keying options; 2–18 positions.

- Complete system approach: accessories such as backshells, protection caps, cavity plugs, and fixing slides help tune sealing and strain relief.

- Supports vehicle networking: dedicated housings and components are available for CAN bus architectures (including Y‑connector and 120 Ω resistor options).

Our Heavy Duty Sealed Connectors provide secure and reliable connections for critical industrial and commercial applications.

Key Features

Heavy Duty Sealed Connector Headers

| Feature | Specification |

|---|---|

| Connector System |

Wire-to-Board, Board-to-Board, Cable-to-Cable |

| Number of Positions |

4, 6, 7, 8, 10, 15, 16, 18 |

| Number of Rows | 2 |

| Centerline (Pitch) | 6 mm (primary), 4 mm and other sizes available |

| PCB Mount Orientation | Vertical |

| Sealable | Yes, designed to provide a sealed connection |

| Housing Material | PBT GF30 (glass-filled thermoplastic) |

| Contact Material | Bronze alloy, with nickel underplating and silver or tin plating |

| Contact Current Rating (Max) | 10A, 20A |

| Operating Voltage | 24 VAC/VDC |

| Nominal Voltage Architecture | 12 V |

| Operating Temperature Range | -40°C to 140°C (-40°F to 284°F) |

| Flammability Rating | UL 94V-0 |

| Secondary Lock | Integrated with poka-yoke feature to enable proper assembly |

| Connector Width | 26.7 mm |

| Connector Height | 33.2 mm |

| Connector Length | 52.2 mm |

| Mounting Type | PCB Mount Header |

Real World Applications

Heavy Duty Sealed Connector Headers

Control units & power electronics (inside sealed enclosures)

- Electronic control units (ECUs) in die cast housings where a compact, sealed header brings the harness to the PCB. Available in straight (180°) and right angle (90°) options for tight spaces.

- Battery management systems (BMS), on board chargers (OBC) and power conversion modules - wire to board terminations that tolerate temperature swings, moisture and vibration.

- Domain and gateway controllers (engine, gearbox, aftertreatment) that need sealed PCB I/O with CAN bus support.

Chassis & safety systems

- ABS/EBS brake control units that require sealed headers for reliable PCB interconnects exposed to road spray and dust.

- Rear axle and suspension actuators (wire to board within control modules).

Drivetrain & thermal management

- E-drive and e-power steering controllers where the header must handle vibration and thermal loads.

- E-fans and e-air compressors - sealed PCB connections in high moisture zones.

- Motors and gearboxes (local controllers and sensor hubs); hydraulic pump controllers; fuel level sensor modules.

Vehicle electronics & networking

- Telematics units and sensor gateways using sealed wire to board interfaces; CAN bus nodes and switch/actuator modules.

Across industrial & commercial transportation

- Designed for trucks and buses, construction equipment, and agricultural machinery; also suitable for special vehicles where dust, water, and vibration are expected.

Learn about our rugged Heavy Duty Sealed Connector Series for harsh environment applications. Watch this video for an overview of the connectors and for step-by-step instructions on inserting and removing contacts, as well as mating and unmating.

Heavy Duty Sealed Connector Series Headers

Q: What makes the new headers unique ?

A: Many modern control units use aluminium die-cast housings, which call for compact, off-the-shelf headers to connect the harness to the PCB inside. The new Heavy Duty Sealed Connector Headers address this with designs suited for die-cast enclosures while maintaining the family’s proven sealing and vibration resistance. They also introduce glued and flanged header concepts that build on the Heavy Duty Sealed Connector Series standard, supporting robust environmental sealing and mechanical strength in demanding vehicle applications.

Q: What contact systems do these headers accept?

A: Heavy Duty Sealed Connector Series headers accept AMP MCP 1.5K, 2.8, 6.3/4.8K, and MCON 1.2 contacts. Depending on contact size, typical max currents range up to 40 A (6.3/4.8K).

Q: How do I achieve IP69K performance?

A: Use flanged tab housings with cover and follow the mounting instructions noted in the Heavy Duty Sealed Connector Series specification; this configuration supports IP69K. Standard sealing is IP67.

Q: Are right angle (90°) headers available?

A: Yes. The new Heavy Duty Sealed Connector Header parts add 90° options alongside 180° vertical styles for tighter enclosures and ECU layouts.

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Header Type Fully Shrouded | One Piece - IDC

-

Connector Product Type Connector Assembly | Housing Assembly

-

Mixed & Hybrid Header No | Yes

-

Connector Shape Rectangular

-

Sealable Yes

-

Connector System Cable-to-Cable | Wire-to-Board | Wire-to-Panel

-

Connector & Contact Terminates To Printed Circuit Board | Wire & Cable

Configuration Features

-

Number of Signal Positions 4 | 8 | 12

-

PCB Mount Orientation Horizontal | Right Angle | Vertical

-

Number of Positions 4 | 6 | 7 | 8 | 10 | 12 | 15 | 16 | 18

-

Number of Rows 1 | 2 | 3

Electrical Characteristics

-

Operating Voltage (VDC) 60

-

Voltage Rating (Max) (VDC) 24

-

Operating Voltage (VAC) 24

Body Features

-

Connector & Keying Code 1 | A | B | C

-

Primary Product Color Black | Gray | Green

Contact Features

-

Contact Type Splicing Contact | Tab

-

Mating Tab Width 1.5 mm [ .059 in ]

-

Mating Tab Thickness .64 mm [ .025 in ]

-

Contact Current Rating (Max) (A) 10 | 16 | 20

-

Contact Mating Area Plating Material Hard Silver | Silver (Ag) | Tin (Sn)

Termination Features

-

Termination Method to PCB Through Hole - Solder

Mechanical Attachment

-

PCB Mount Retention Type Boardlock

-

PCB Mount Alignment With

-

Mating Alignment With

-

PCB Mount Retention With

-

Panel Mount Feature With

-

Connector Mounting Type Board Mount | Panel Mount

Housing Features

-

Centerline (Pitch) (mm) 2.5 | 4 | 6

-

Centerline (Pitch) (in) .098 | .157 | .236 | .24

Dimensions

-

Connector Length 52.2 mm [ 2.05 in ]

-

PCB Thickness (Recommended) (mm) 1.5 – 1.6

-

Connector Width 26.7 mm [ 1.05 in ]

Usage Conditions

-

Operating Temperature (Max) (°C) 125 | 140

-

Operating Temperature (Max) (°F) 257 | 284

-

Operating Temperature Range (°C) -40 – 140 | -40 – 125

-

Operating Temperature Range (°F) -40 – 284 | -40 – 257

Operation/Application

-

Solder Process Wave Solder Capable

-

Shielded No | Yes

-

Circuit Application Power | Power & Signal | Signal

Industry Standards

-

UL Flammability Rating UL 94V-0

-

IP Rating IP67 | IP69K | IP6K9K

Packaging Features

-

Packaging Method Box | Carton Box With Tray | Package | Tray

-

Packaging Quantity 1 | 84 | 160 | 168 | 350

Catalog

- Heavy Duty Sealed Connector Series (English) Heavy Duty Sealed Connector Series is designed to meet the rigorous demands of the commercial vehicle industry and off-road applications that require the highest standards of performance.

Are you sure you want to close chat?

To begin your chat with TE please enter your details