Flexible high force processing solutions

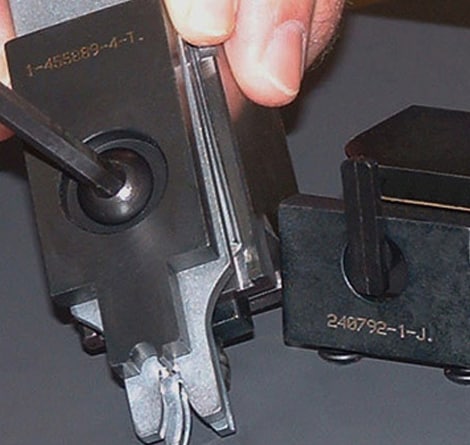

Processing large wire sizes and terminating high voltage wire connectors requires a high performing, highly-engineered solution. The TE high force lineup gives you the power needed to process large wire applications in a fast, flexible and affordable format. Our HV-CP machine takes the complexity and long preparation times out of high voltage cable processing, while our HF-20 and HV-20 bench-top pressing machines are capable of terminating cables up to 120mm2 (AWG 4/0). Plus, the TE modular die platform allows you to use a wide variety of unique die sets in holders that can be installed into either press.