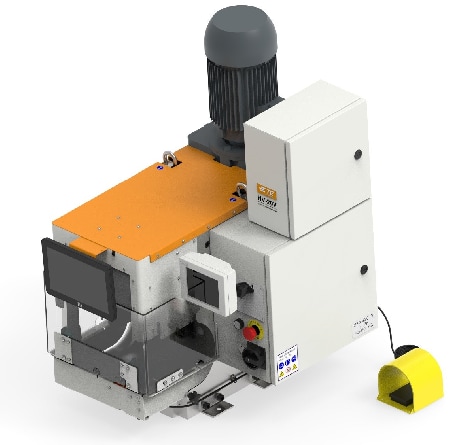

Pre-crimp Quality Analysis with Vision System

TE Connectivity’s (TE) robust, compact, high-force benchtop machines equipped with the HV-20 vision system analyze cable termination components before crimping, ensuring robust performance. The system includes a vision computer, a front-mounted monitor, three cameras, and an internal LED strip to capture and assess die set, terminal, and cable conditions for successful crimping.

Features

- The die vision system checks multiple points before the crimp to prevent incorrect or poorly positioned tooling, terminals, and cables

- Minimizes dependence of operator’s skill

- Drastically reduce risk of scrap, thus creates cost saving

- The crimp quality monitor (CQM) detects errors during crimping

- Can be integrated in customer’s manufacturing execution systems (MES) for data exchange

- Visual inspection allows the user to define tight windows of variability

- Anything detected to be outside of these acceptable windows will inhibit crimping

- The crimps that are allowed by the die vision system will have consistent diameter, cable position, and terminal position

Product Specifications

| Description | Specification |

|---|---|

| Force | 178kN (20T) |

| Max Wire | 120mm2 |

| Variable Stroke (Sec) | 1.3 - 8.3 Sec2 |

| Speed (RPM) |

88 - 1800 RPM |

| Power | 3kW |

| Supply | 200V & 400V |

| Stroke / Shut Height | 44mm / 158.4mm |

| Weight |

390kg |

| Network/MES |

RJ-45 / MQTT |

| Particle Vacuum | Yes |

| Guard Auto Lift | Yes |

| Crimp Quality Monitor | Yes |