USB Versatility

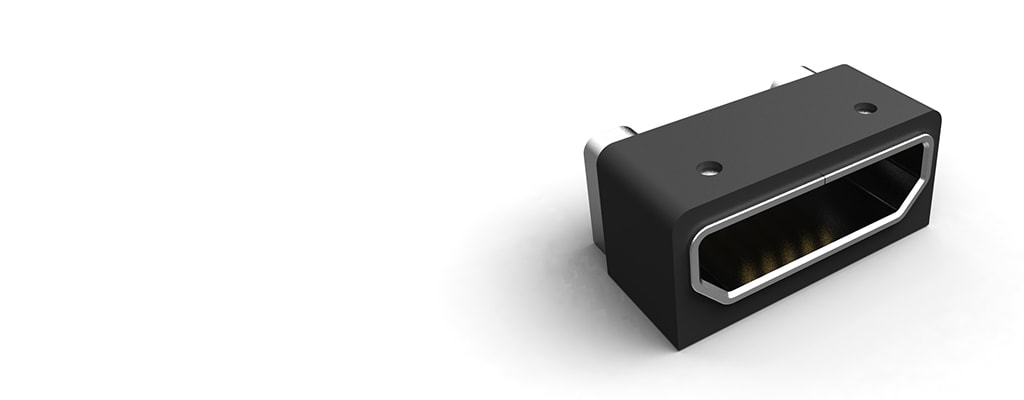

TE's Micro USB connectors are available in a range of design options, including splash-proof receptacles like this one. Here is a brief overview of the types and options to consider when designing for micro USB 2.0.

Our micro USB connectors are well known for their reliability, robustness, and the system’s versatility in meeting all USB applications. The TE USB system is a complete interconnection technology for I/O devices and has many variants available, ranging from DIP type soldering, SMT soldering, standard mount, reverse mount, and mid mount.

The USB (Universal Serial Bus) is a standard product controlled by USB Implementer's Forum. USB is characterized by widespread market adoption and consists of several form factors to accommodate different device requirements. The Micro USB series are mostly used in mobile devices and are the smallest connector series in the USB family. TE’s USB connectors combine high speed data capabilities and a charging function in one connector.

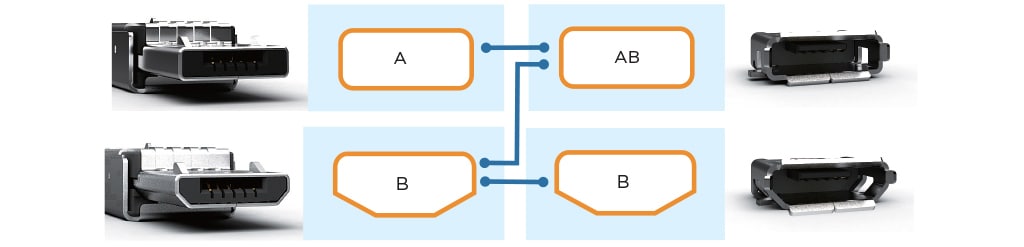

Plug and Receptacle Types

Mating Types

A and B Plugs; B and AB Receptacles

Type A plugs are typically used for connection to “master” devices. Type B plugs are used for connections to “slave” devices. The device itself either features a receptacle that can accept only Type B (slave) plugs or both Type A and Type B plugs (device can function as master or slave). This receptacle is called an AB receptacle.

Soldering Type

Solder Mount Technology (SMT)

Dual in-line package (DIP) type receptacles feature two or four through-hole solder legs that provide additional strength to the connector. They prevent the connector from being ripped off the board if an exceptionally large force is applied to the connector (for example, when the device is dropped with an inserted plug).

Mount Type

Standard vs. Mid Mount

A micro USB connector has a height of 2.51mm. With standard onboard mounting, this height is a given; however, sinking the connector into the board can reduce the height in the end application. This treatment creates a mid mount. Depending on the requirements, mid-mounting can achieve several heights.

Reversed Mount

The micro USB plug always needs to be plugged into devices with the USB logo facing the user. Reversed types allow for mounting on the opposite board site while the plug insertion direction is still correct. This functionality is achieved by flipping the mating interface. Reversed mounting is available in both standard reversed (on board) and reversed mid mount types.

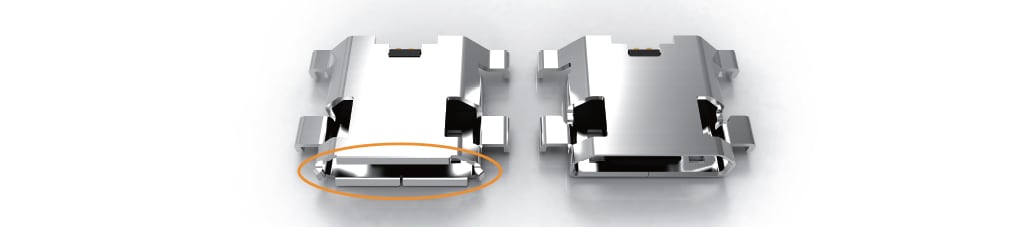

Flange vs. Flangeless

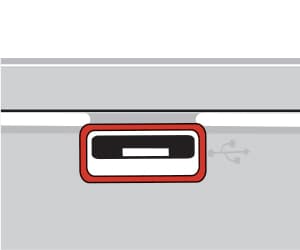

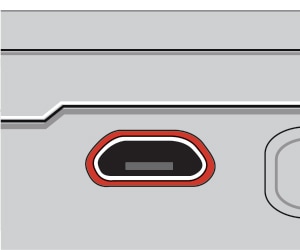

Micro USB with flange (circled in orange) vs. flangeless receptacle

With Flange

Appearance of Micro USB Connector

The micro USB connector with flange leaves a gap between the connector and the phone cover. The gap allows for dust intrusion, and from an aesthetic point of view is less desirable.

Flangeless

Appearance of Micro USB Connector

The flangeless micro USB connector looks better in combination with the cover. The function of the flange is picked up by the shell.

Splash Proof

Sealing

Added Protection for Your Devices

Either axial sealing or radial sealing to the device cover is possible. Splash-proof sealing material is all around the outside of the cover. Water proof sealing can be applied as well.