RTD Temperature Sensor Elements

TE Connectivity’s RTD temperature sensor elements are designed to provide precise, stable measurement in extreme temperature applications. These elements offer high value through proven design, ease-of-use, reliable performance and quick availability. Precise temperature measurements can be made in extreme environments. Whether you’re working on a new engineering design or optimizing an existing one, our RTD temperature sensor elements are easy to use in many industries and applications. The linear output requires low engineering intervention and we make these elements available quickly in most form factors.

Understanding RTD Sensor Elements

An RTD sensor element is the temperature sensing component that changes in resistance based on changes in temperature. For platinum elements, there are two basic types – thin film elements where the platinum is sputtered onto a ceramic base via photolithography and etching and wire-wound elements where a thin platinum wire is wrapped and fused inside a glass casing or embedded in ceramic. Elements are contrasted with RTD probes or assemblies that consist of an RTD element, a sheath or housing, an epoxy or filler, extension leads and sometimes a connector or termination.

Product Features:

Capabilities of TE's RTD Sensor Element Portfolio

- Precise measurement in extreme environments

- Ease of application and use

- Engineered to withstand extreme temperatures -200°C to +600°C

- International industrial standards (IEC 60751:2008)

- Greater engineering efficiency due to linear output

- Complete range for numerous applications

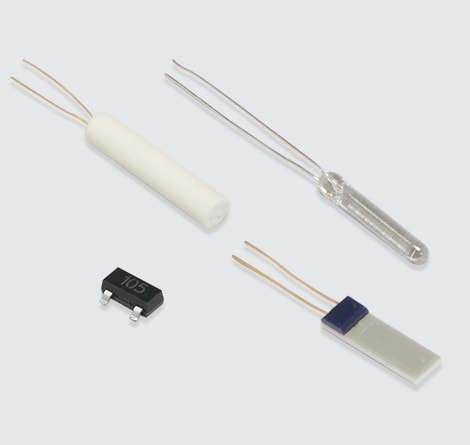

RTD Sensor Element Types

The two most common types of RTD sensor elements are thin film elements and glass wirewound elements. Wirewound elements typically come in two types – glass and ceramic. Some SMD elements are also manufactured including a 1206 SMD version which TE also manufactures, a Ni1000 element in a SOT23 package and even a digital sensing element, the TSYS01 which contains an internal Ni1000 sensing element.

A thin film element is manufactured using a technology called photolithography. This technology enables sensing element to be more rugged, smaller in size, more accurate, and more cost effective than traditional wire-wound elements. Since wire-wound elements are labor intensive, they tend to be more expensive. However, there are advantages to wirewound elements, see below a summary for some of the advantages of each style.

Thin-film element advantages:

- Lower cost

- Fast response time

- Small size

- Good vibration resistance

- Good thermal shock resistance

- Low thermal mass

Wirewound element advantages:

- Wider operating temperature range

- Customizable base resistance values

- Higher source currents available

- High accuracy over a broader temperature range

- Larger diameter lead wires

- Lower self-heating

Applications

RTD sensor elements are especially suitable for applications that require a higher operating temperature range than thermistors, require good accuracy over a wide range of temperatures or applications that require good stability and low drift over time. Featured applications include:

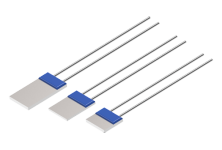

Platinum Thin Film RTD Sensors

The platinum thin film RTD sensor consists of a structured thin film of platinum coated onto a ceramic substrate, passivated by a glass coating. The most common types of platinum thin film RTD sensors are the Pt100 and the Pt1000. The Pt100 has a base resistance value of 100Ω at 0°C (ice point), and the Pt1000 has a base resistance value of 1000Ω at 0°C. The most common temperature coefficient of resistance (TCR) for these sensors is 3850 ppm/K, meaning a change in resistance of 38.5 Ohms between 0°C and 100°C for the Pt100. Both the Pt100 and the Pt1000 are available in a range of temperature accuracies and dimensions.

e

e

e

e