Revolutionizing Automotive Automation

As the industry moves toward zonal electrical/electronic (E/E) architectures, TE solutions help OEMs and suppliers simplify harness design, reduce complexity, and accelerate the shift to scalable, automated manufacturing for future-ready vehicles.

ROBOT

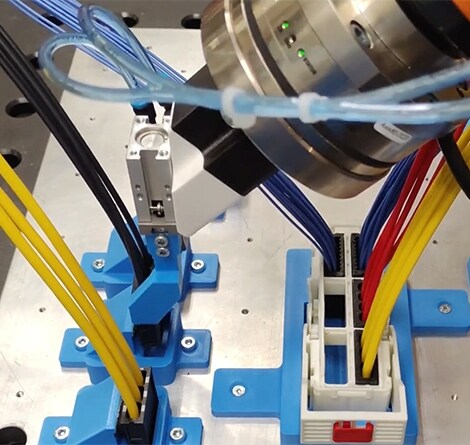

Precise robotic gripping, making it scalable for fully automated production lines.

FUTURE

Future-proof system integration - designed with standardized specifications ensuring compatibility with OEMs and suppliers.

NEXT

Advancing next generation mobility with fully-automated, end-to-end automotive wiring systems.

Advancing Vehicle Automation for Next-Gen E/E Architectures

As an innovation partner, TE was proud to support the Next2OEM initiative—funded by the German Federal Ministry for Economic Affairs and Energy (BMWE)—and contributed significantly to advancing automated processes in wiring harness production. The project focused on end-to-end automation of wiring systems across the full value chain, from harness manufacturing through installation in the vehicle. TE’s contributions were especially critical in the early design of components and mechanical interfaces, enabling stable automated handling and seamless integration into the broader process flow for next-generation E/E architectures. Through this work, our advanced connector geometry—tailored for automated manufacturing and evolving E/E requirements—helped establish new benchmarks for integration, scalability, and efficiency across the wiring harness value chain.

Automation and Next-Gen E/E Architectures Begin with Smart Design

As next-generation E/E architectures transform vehicle systems, the shift is redefining how wiring harnesses are designed and built. At TE Connectivity, automation begins not on the factory floor—but at the component design stage. Our advanced connector geometries are purpose-built for automated handling, enabling seamless integration into modern electrical systems.

TE’s automation-ready connectors help OEMs and suppliers streamline production, reduce complexity, and accelerate the transition to smarter, more scalable manufacturing across the industry.

Watch our Innovation in Action

This new design drives efficiency and precision—empowering end-to-end automation from suppliers to OEM integration for future-ready vehicles.

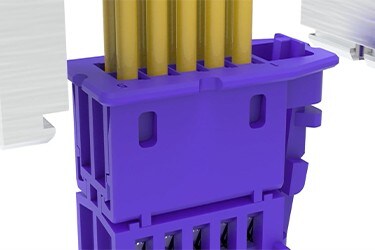

Highlights of this Groundbreaking Automation-Ready Connector Geometry

- Automation-Optimized Design

The connector geometry allows for precise robotic gripping, making it scalable for fully automated production lines.

- Future-Proof System Integration

Designed with standardized specifications, the new geometry ensures compatibility across various OEMs and suppliers.

- Advancing Next-Generation Mobility

The design marks an important step towards end-to-end automation of wiring systems while empowering fully automated manufacturing processes and strengthening end-to-end automation capabilities in the automotive industry.

Driving Harness Assembly Efficiency through Standardization and Automation

TE Connectivity is proud to be a part of the ARENA2036 ecosystem — a hub of innovation supported by the German Federal Ministry of Research, Technology, and Space (BMFTR). Together, we’re shaping the future of work, mobility, and production through collaboration and cutting-edge research.

DIN 72036 standard

As a key partner in the Wire Harness Standardization Initiative (SILS), TE Connectivity is driving progress toward the automation and standardization of wire harness production within the framework of DIN 72036 — setting new benchmarks for efficiency and innovation across the industry.

TE’s contact systems are engineered and evaluated to meet the requirements of the market’s leading automated wire processing technologies, ensuring full compliance with DIN 72036 and reinforcing our commitment to shaping the future of connected manufacturing.

Automation-Ready (DIN 72036 Standard) Product Portfolio

Find more options

The Future of Automotive Innovation, Let’s Go There Together