At productronica 2025, Cellios, TE Connectivity, and other technology partners will present a fully automated manufacturing cell-a technological step toward efficient, data-driven cable harness production.

Published

11/11/25

Media Inquiries

Alex Rhodes

TE Connectivity

Tel:+1.717.418.5734

Email: alex.rhodes@te.com

Ann-Kathrin Knorn

TE Connectivity

Email: annkathrin.knorn@te.com

Bensheim, Germany – 11.11.2025

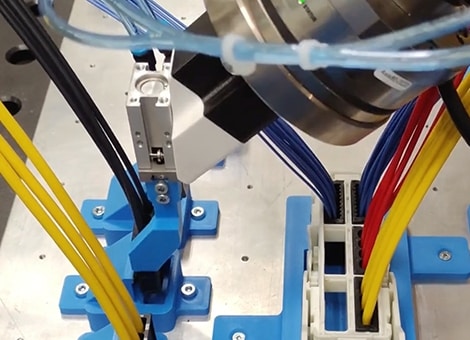

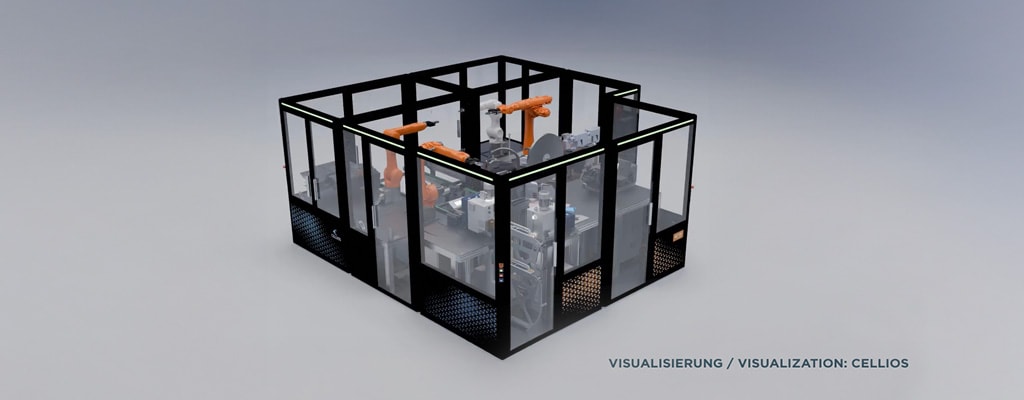

At productronica (Nov. 18–21, Munich Trade Fair Center) Cellios, TE Connectivity, a world leader in connectors and sensors, and other partners will present a fully automated manufacturing cell for wire harnesses –starting from individual components all the way to the tested cable assembly – all within one integrated system. The live demo at the Cellio´s booth (Hall B4, Booth 131) will show how previously manual manufacturing steps can now be implemented in a robot-guided, data-driven and traceable automated manner for the first time.

As a key development partner, TE contributes terminals, connectors and application tooling, and comprehensive expertise in the development of standardizable, automatable connector systems – the basis for process reliability and a high degree of automation.

“By using automated production cells, we will be able to place production closer to our customers, increase supply security, and create the basis for flexible, networked manufacturing processes right through to downstream assemblies,” says Stefan Glaser, TE director of product management.

In the wake of increasing electrification, more complex vehicle electrical systems and shorter development cycles in the automotive industry, automated cable harness production offers a decisive advantage in terms of productivity and quality. The solution enables fully data-supported traceability and can be flexibly adapted to different cable sets and OEM specifications, an important step toward networked, digitally controlled vehicle production.

The production cell was developed through a collaborative effort in robotics, sensor technology, and software integration. The focus is on system architecture, control logic, and modular component integration—the basis for variant capability and production-oriented implementation in wiring harness manufacturing.

During development, findings from the BMWK-funded Next2OEM research project were incorporated, driving further advancements in the solution’s design and performance. The innovation was recognized with a nomination for the productronica Innovation Award in the “Cables, Coils & Hybrids” category.

“I am proud when I see what we have achieved together with our partners such as TE Connectivity over the past two years—from our last appearance at productronica to today,” says Arik Lämmle, CEO and co-founder of Cellios. “Through genuine collaboration and a shared goal of bringing value creation back to this country, we are demonstrating that we can really make a difference and bring about lasting change in our industry.”

Trade visitors and media representatives are invited to experience the demo at booth B4.131 and talk to experts from TE and Cellios about technical details, integration options and economic potential.

About TE Connectivity

TE Connectivity plc (NYSE: TEL) is a global industrial technology leader creating a safer, sustainable, productive, and connected future. As a trusted innovation partner, our broad range of connectivity and sensor solutions enable the distribution of power, signal and data to advance next-generation transportation, energy networks, automated factories, data centers enabling artificial intelligence, and more.

Our more than 90,000 employees, including 10,000 engineers, work alongside customers in approximately 130 countries. In a world that is racing ahead, TE ensures that EVERY CONNECTION COUNTS.. Learn more at www.te.com and on LinkedIn, Facebook, WeChat, and Instagram.