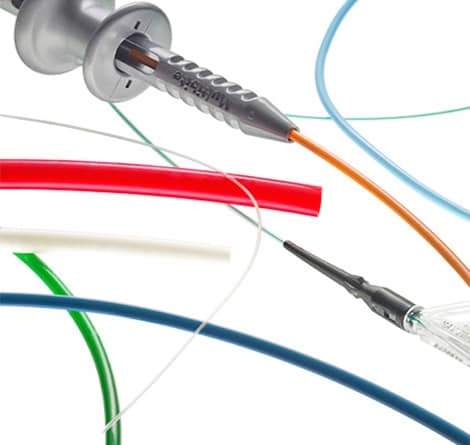

Protection, insulation & manufacturing aids for your medical device

Medical-grade heat shrink tubing offers abrasion protection in medical instruments, insulation in laparoscopic electrosurgical devices, mechanical protection and insulation of highly flexible joints and as a processing aid for interventional applications. And with more than 60 years of polymer engineering experience, we offer Fluoropolymers, Polyolefins, Pebax and custom medical-grade tubing solutions.

Materials

- FLUOROPOLYMERS

o PVDF (Polyvinylidene fluoride)

o FEP (Fluorinated ethylene propylene)

- POLYOLEFINS

o HDPE (High-density polyethylene)

o LDPE (Low-density polyethylene)

- PEBAX

- Custom Compounding

Constant Optimization of Proven Technology

Design, select, optimize

| Raw Material | Product Design | Material Properties | Finishing | Value Add |

|---|---|---|---|---|

Custom compounding |

Single & dual wall |

Colour |

Spooled |

Pad printing |

Broad material range |

Adhesive inner wall |

Radiopacity |

Cut to length |

|

Expansion ratios ≤ 4:1 |

Peelable |

Cut & slit |

||

Customizable compression strength |

Double-bagged |

Application Guide

| Application | Option 1 | Option 2 |

|---|---|---|

Manufacturing process aids for interventional applications |

MT-FEP (FEP) |

MT-LWA (LDPE) |

Interventional shaft encapsulation |

MT-PBX (PEBAX) |

|

Abrasion protection for electrosurgical devices |

MT-2000 (HDPE) |

MT-1000 (PVDF) |

Rigid abrasion protection for laparoscopic and in-vivo instruments |

MT-1000 (PVDF) |

MT-2000 (HDPE) |

Insulation for electrosurgical devices |

MT-2000 (HDPE) |

MT-3000 (PVDF) |

Strain Relief |

MT-5000 (LDPE) |

MT-3000 (PVDF) |

MT-LWA (LDPE) |

MT-LWA (LDPE) |

Fluoropolymer, Polyolefin & Pebax

Manufacturing Locations

Technical Resources

Frequently Asked Questions

FAQs

Q: What materials are available for TE's medical-grade heat shrink tubing? (e.g., PTFE, FEP, PEEK, Polyolefin, etc.)

A: We offer medical heat shrink tubing products formulated from Fluorinated ethylene propylene (FEP), Polyvinylidene fluoride (PVDF), High-density polyethylene (HDPE), Low-density polyethylene (LDPE), Linear low-density polyethylene (LLDPE), and PolyEther-block amide (PBX).

Q: What are the available wall thicknesses and tolerances of TE's medical-grade heat shrink tubing?

A: Depending on the material and size, but we can offer tubing as low as 0.001" (0. 00254 cm)

Q: Does TE's medical-grade heat shrink tubing comply with FDA regulations for medical devices?

A: Yes. MAF number and ISO certification available upon request. Connect with our our experts for more information.

e

e

e

e

e

e

e

e

e

e

e

e