Access and delivery devices are becoming increasingly complex as we look to balance multiple functionalities with enhanced performance while maintaining the lowest overall profile. During this webinar, our device design expert discusses the optimization of thin wall sheath constructions by using laser cut metal hypotubes for greater precision & lowest profile. This webinar is useful for designers of access or delivery systems for application in minimally invasive vascular, structural heart, and electrophysiology devices.

Catheter Technologies

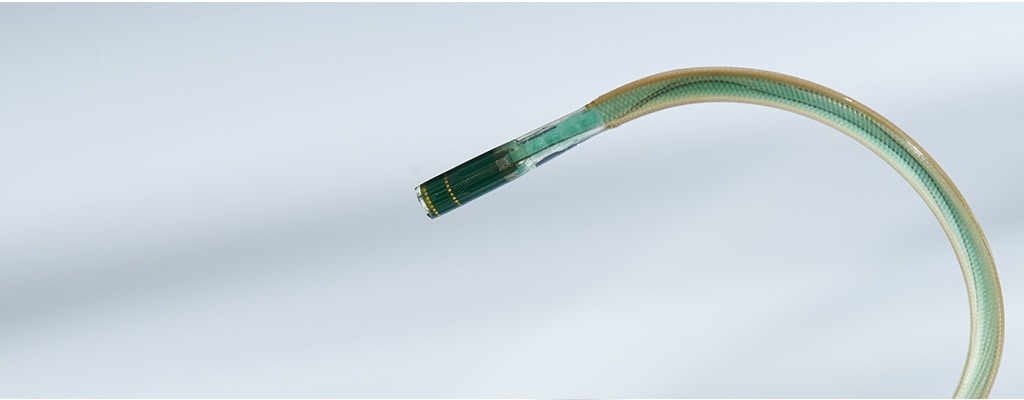

From access to closure, TE is a trusted partner to the world’s leading medical device companies in the design, development, and manufacturing of complex and optimally engineered catheter components/assemblies for various interventional therapies. Our solutions include reinforced passive access & delivery sheaths, introducer sheaths, steerable catheters, and complex reinforced & steerable mutilumen delivery catheters.

We’re more than a components supplier. With TE you get an integrated solutions partner who can develop your idea from prototyping to volume manufacturing. This connected value gives you a competitive advantage in today’s marketplace.

Why TE?

- Engineering expertise: Early design collaboration takes you from concept to production, and beyond.

- Extensive manufacturing capabilities: TE has the expertise in a range of manufacturing processes to develop highly engineered components and value-added sub-assemblies.

- Global footprint: Improved supply chain resilience, responsiveness and access to emerging and low-cost manufacturing markets.

- End user focus: We design for ergonomics, small spaces, high speed, high performance, and reliable connectivity.

Structural Heart Intervention

Applications

- TAVR (Transcatheter Aortic Valve Replacement)

- TMVR/r (Transcatheter Mitral Valve Replacement / repair)

- Tricuspid Valve Replacement

- PulmonicLAA (Left Atrial Appendage)

- Heart Failure

- SH Closure

Electrophysiology Intervention

Applications

- Therapeutic

- Ablation Treatment Catheters

- Irrigated Tip / Contact Force

- Pulse Field Ablation (PFA)

- Diagnostic

- ICE (Ultrasound)

- 3D Mapping

- Pulmonary Vein Loop Mapping

Peripheral Vascular Intervention

Applications

- Endovascular Aneurysm Repair (EVAR)

- Balloon Catheters (PTA / PTCA)

- Thrombectomy Devices

- Atherectomy Devices

- Stent Delivery Systems

Endoscopy

Applications

- Bronchoscopes

- Gastroscopes

- Disposable / Single Use Endoscopes

Manufacturing Capabilities

We can scale our design and production services to match your needs and grow with you from prototype to pilot manufacturing, providing full-service rapid prototyping and flexible manufacturing capabilities close to your development teams. With multiple sites, we can offer continuity of supply with extensive in-house capabilities, including comprehensive technologies for catheter, catheter tubing, and guidewire manufacturing.

Choose TE as your catheter assembly development partner to leverage system-level design integration and engineering expertise in a wide array of manufacturing capabilities.

Capabilities

- Liner Stretching - Stretch PTFE liner on Mandrel

- Braiding / Coiling - Braid over mandrel or over lumen; precision needed for torquibility and kink resistance

- Annealing / Termination - Terminate the braid

- Extrusions - Thermoplatic, Heatsrink, PTFE

- Assembly - Assembly of liner jackets or metal consent

- Reflow / Bonding - Fusing of liner jackets through ovens and bonding of pull wires mandrels

- Mandrel Pulling - Pulling out the mandrel

- Cut to Length - Cutting catheter to shape

- RF Tipping - RF tipping for mandrel termination

- Inspection and Testing - Final inspection outside; borescope inspection and testing

- Packaging and labeling

- Drilling, punching and skiving

- Simulation

- Wire-based (coax, electrical)

- Fine wire termination

- Sterilization

Manufacturing Locations

Technical Resources

When designing an aspiration catheter, one of the biggest challenges is finding the right balance between suction strength and the ability to reach the distal neurovasculature, especially given the limitations in vessel size. In this webinar, you will hear TE's experts talk about the performance need and challenges associated in designing catheter that meets the performance objectives of navigating complex vasculature as well as the process challenges and solutions during manufacturing of thin-walled catheters.

e

e

e

e

e

e

e

e