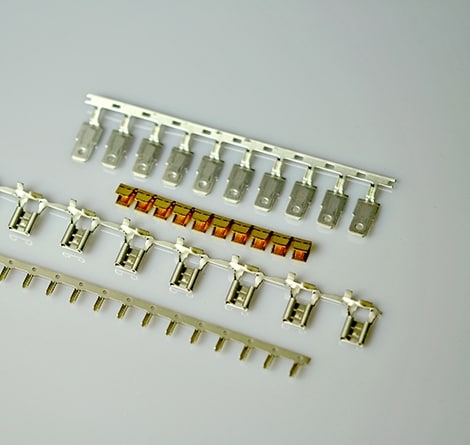

Serrated Crimp Magnet Wire Contacts

AMPLIVAR terminals and splices are magnet wire connectors featuring crimp barrels with sharp edged serrations that pierce magnet wire insulation without wire stripping. This unique crimp results in a solderless and airtight connection without the contaminants, cold solder points, weld burns and wire embrittlement associated with thermal termination. AMPLIVAR products are compatible with high throughput automated termination systems and support up to three magnet wires (copper or aluminum) and one lead wire in a single crimp. Terminals are available in a variety of styles, including ring tongue and FASTON straight, flag or stator receptacles. Common applications include electric motors, compressors, fuel pumps and power tools.

Product Features

| Number of Serrations |

5, 7, 9 |

Input / Output Types | Splice Crimp Only, Pin Socket, FASTON Tab, Ring Tongue, or Stator Receptacle |

| Wire Size (CMA / AWG) | 100 - 22,000 / 29-11 |

Splice Types | Pigtail, Thru |

| Max Number of Wires |

Magnet Wire: 3 Lead Wire: 1 |

Materials / Plating | Base: Brass, Copper Alloy, Phos. Bronze Plating: Tin, |

| Max Wire Diameter Ratio | 2:1 | Max Operating Temperature (°C) | 150 |

| Type of Wire |

Magnet Wire (Cu / Al) & Stranded Lead Wire | Agency Approval(s) |

UL |

Featured Products

Electromechanical connection of two or more wires entering the contact from the same direction. Serrations are offset in the crimp barrel.

Electromechanical connection of two or more wires entering the contact from opposite directions. Serrations are centered in the crimp barrel.

AMPLIVAR terminals featuring a FASTON receptacle with stator cavity retention barbs. The receptacle is designed to fit the motor stator cavity while the serrated barrel terminates magnet wire from the motor coil.

AMPLIVAR terminals featuring a ring contact designed for joining wiring to a stud or screw connection.

AMPLIVAR Terminal with FASTON Receptacle - Straight & Flag

AMPLIVAR splice combined with straight FASTON quick disconnects, removing the necessity for separate stranded wire terminal connections and lead wires.

A splice designed to terminate a combination of up to 6 magnet wire and 2 stripped lead wires. The splice contains two cavities that separate and cradle magnet wire and lead wires prior to crimping.