Product Group

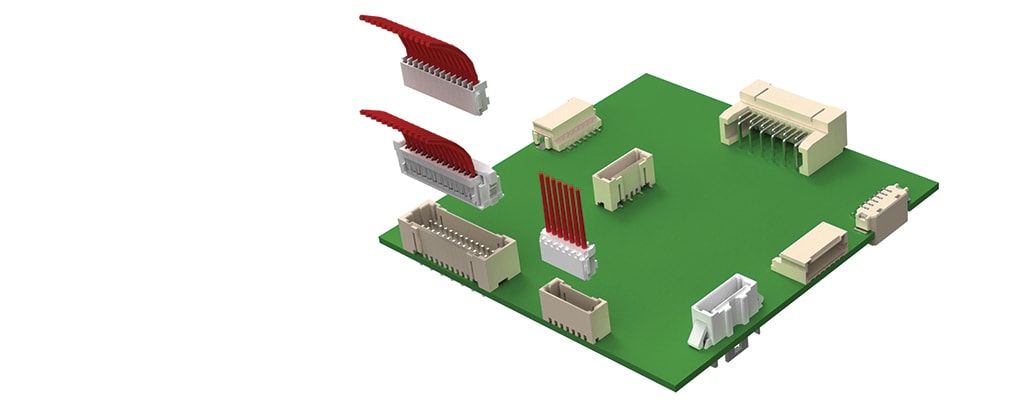

AMP Common Termination (CT) Connectors

Our AMP CT connector system consists of an extensive product offering and broad industry usage, including standard CT (2.0 mm pitch), Mini CT (1.5 mm) and Micro CT (1.2 mm).

AMP CT Connectors

Designed with contacts on 2.0mm, 1.5 mm, and 1.2 mm pitch, all the product lines consist of a wide variety of board side headers that mate with the contacts and housings we offer.

Select Applications

- Business equipment

- Industrial machines

- PCs

- Printer

- Audio

- Air conditioner

- Lighting

- Where signals or power are routed

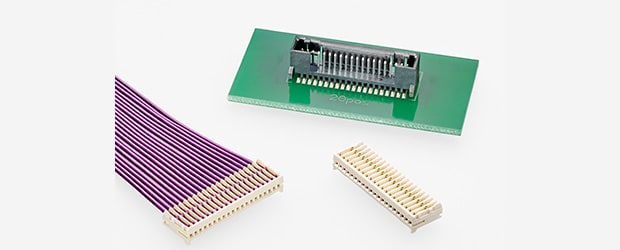

1.2 mm AMP Micro CT Connectors

Product Overview

With superior performance in its harness making capability, our AMP Micro CT connectors and cable assemblies can provide an economical wire routing solution for power or signal needs, potential printed circuit board space savings, efficiency improvements and superior performance.

A variety of harness-making machines are available ranging from hand tools for low volume production to high-speed automatic crimping machines for medium to high volume productions. AMP high-speed automatic crimping machines are easier to operate, helping eliminate the need for tedious work of changing parts inside the equipment to adapt to changes in harness styles.

1.5 mm AMP Mini CT Connectors

Product Overview

Our AMP Mini CT connectors are miniature wire-to-board and wire-to-wire connectors. Like the standard AMP CT connector series, these connectors are tailored for improved harness productivity and feature a compact design with contacts on 1.5 m pitch.

Wire-side connectors can be used to produce a variety of harness styles by fully automatic high-speed assembling machines.

2.0 mm AMP CT Connectors

Product Overview

AMP CT connectors are a miniature wire-to-board and wire-to-wire interconnect

solution. The AMP CT connector series has proven performance in its harness making capability.

Two types of housings are available, including Crimp and Mass Terminated (MT), which are preloaded with insulation displacement contacts. The box or shrouded headers are highly resistant to scooping at mating/unmating.

A variety of harness-making machines are available ranging from hand tools for low volume production to high-speed automatic crimping machines for medium to high volume productions. AMP high-speed automatic crimping machines are easier to operate, eliminating the need for tedious work of changing parts inside the equipment to adapt to changes in harness styles.