Complex Catheters

Complex reinforced & steerable multi-lumen delivery catheters are highly specialized medical devices engineered to deliver therapies, instruments, or diagnostic tools with precision to anatomically challenging or hard-to-reach locations. These catheters incorporate advanced design elements, such as reinforced structures for durability, steerable tips for precise navigation, and multiple lumens to enable simultaneous tasks.

With our deep expertise in multi-lumen, deflectable, and steerable shaft construction, combined with advanced sensor integration, fine wire channeling, and precise termination techniques, TE Connectivity (TE) is your partner for delivering efficient, optimized solutions tailored to your complex catheter shaft needs for a range of your intended applications including structural heart, electrophysiology and endoscopy. Our streamlined supply chain for metals and polymer components allows us to engineer for quality and performance.

Configurations

Steerable catheter shafts

TE has broad experience supporting our customers in the development and production of their complex catheters with steerable shafts, featuring single, dual, and quad-directional control, helping to ensure precise delivery to their intended targeted treatment location.

Learn More

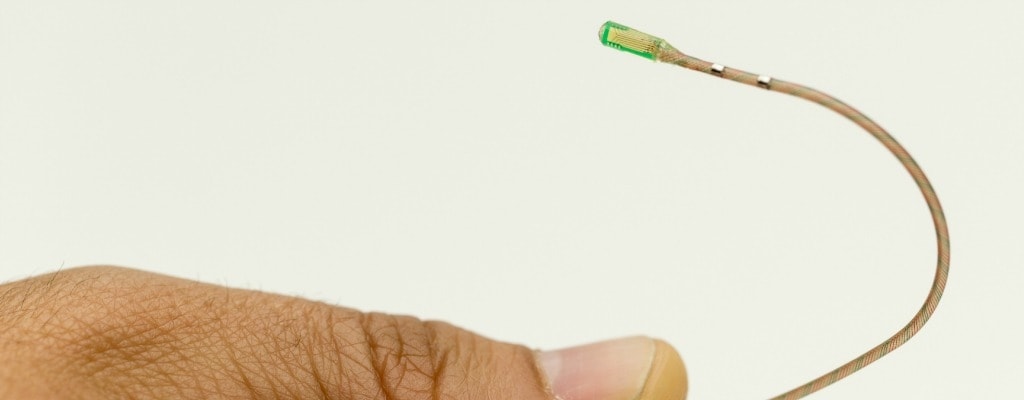

Sensor technology

TE can seamlessly integrate sensors for pressure, position, temperature, fiber optics, and mapping into the smart catheter through advanced multi-lumen construction, fine wire channeling , and precise termination techniques

Ablation catheters

TE has experience producing advanced, complex catheters for precise customer-identified treatments, including pulse field ablation, standard ablation, and cryoablation techniques. Partnering with our expert engineers helps to ensure reliable, high-performance solutions tailored to meet your specifications, delivering optimal clinical results.

Catheter Manufacturing Capabilities

Manufacturing Capabilities

| Capabilities | Description (what & how) |

|---|---|

| Liner Stretching |

Stretch PTFE liner on mandrel. |

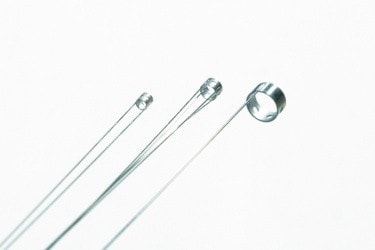

| Braiding/Coiling |

Braid over mandrel or over lumen; the precision needed for torquability and kink resistance. |

| Annealing/Termination |

Terminate the braid. |

| Extrusions | Thermoplastic, heat shrink, PTFE. (Learn More) |

| Assembly |

Assembly of liner jackets or metal consent. |

| Reflow/Bonding |

Fusing of liner jackets through ovens and bonding of pull wires mandrels. |

| Mandrel Pulling |

Pulling out the mandrel. |

| Cut to Length |

Cutting catheter to shape. |

| RF Tipping |

RF tipping for mandrel termination. |

| Inspection and Testing |

Final inspection outside; borescope inspection and testing. |

| Packing and Labeling |

Packaging and labelling processes for bulk non-sterile and sterile finished goods in compliance with industry standards. |

| Drilling, Punching, and Skiving | Mechanical processes for component and device manufacture. |

| Simulation | Predictive Engineering and Simulation team can perform structural, flow, thermal, mold flow, light / optics, additive manufacturing and extrusion simulations. |

| Wire-based (coax, electrical) |

TE specializes in cable designs that enable high-speed transmission of imaging data, while incorporating various functionalities such as illumination and electrical transmission into a flexible and reliable product component |

| Fine Wire Termination | Using its extensive experience in fine wire termination, TE integrates copper and fiber connectivity into our cables, producing highly flexible, yet rugged cables for the operating room. (Learn More) |

| Sterilization | Sterilization processing and validation supported with our external vendors. |

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e