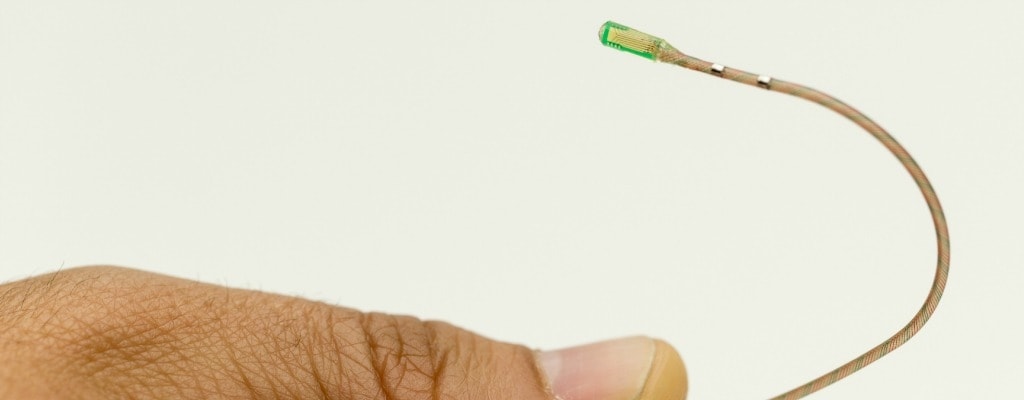

Steerable Catheters

Advancements in structural heart, EP and endoscopy have driven an increased need for deflectable and steerable sheaths to reliably deliver intravascular treatment options to previously inaccessible locations. Combining advanced design, development, and catheter manufacturing capabilities, TE presents a wide variety of steerable catheter sheath solutions to enable the latest developments in catheter technology.

Configurations

1-way / 2-way/ 4-way steerable

Steerable shaft configurations designed to suit the application requirements from simple single plane deflecting catheters to catheters with steering in 2 or 4 planes and at single or multiple deflection points.

Bowden Cable can be integrated in the design - this is a flexible cable used to transmit mechanical force or energy by the movement of an inner wire within an outer flexible casing. The design allows the cable to transmit force in one direction—usually pull—and is widely used in various applications where flexibility and control are required.

Braided & Coiled shafts

Braid reinforced steerable shafts have high bust pressure and superior torque control.

Coil reinfroced steerable shafts have better kink resistance with good flexibility to navigate tortuous anatomy.

Combinations with a transition from a braided to a coiled shaft can also be designed and supplied.

Lasercut hypotube (LCHT)

Lasercut hypotube (LCHT) reinforced shafts can provide superior performance in trackability and pushability with very good kink resistance and lumen integrity due to the superior hoop strength of the LCHT over Braid and Coiled designs. The LCHT design also facilitates 1:1 torque transmission, giving accurate control of the catheter tip in the body.

Manufacturing Capabilities

| Capabilities | Description (what & how) |

|---|---|

| Braiding/Coiling | Braid over mandrel or over lumen; precision needed for torquibility and kink resistance |

| Annealing/Termination | Heat treatment and braid wire termination to ensure smooth transition and no exposure or unravelling of braid wire. |

| Laser Cut Hypotube | Hypotube laser-cut with a specific cut pattern designed to optimise performance for the specific application (Learn more) |

| Extrusions | Thermoplastic, heat shrink, PTFE (Learn more) |

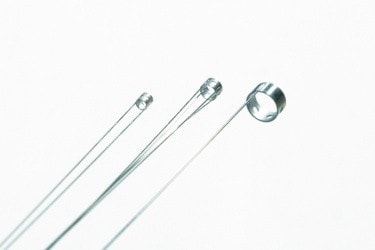

| Pull-wire Assemblies | Ring welded to wires to enable the steering function in the catheter. (Learn more) |

| Assembly | Assembly of liner jackets or metal consent |

| Reflow/Bonding | Fusing of liner jackets through ovens and bonding of pull wires mandrels |

| RF Tipping | Radio Frequency (RF) technology for formation of atraumatic distal tips. |

| Inspection and Testing | Final inspection outside; borescope inspection and testing |

| Packing and Labeling | Packaging and labelling processes for bulk non-sterile and sterile finished goods in compliance with industry standards |

| Simulation | Structural, flow, thermal, mold flow, light / optics, additive manufacturing and extrusion simulations. |

| Wire-based (coax, electrical) | Cable designs that enable high speed transmission of imaging data, while incorporating various functionalities such as illumination and electrical transmission into a flexible and reliable product component (Learn more) |

| Fine Wire Termination | Integrating copper and fiber connectivity into our cables, producing highly flexible, yet rugged cables for the operating room. (Learn more) |

| Sterilization | Sterilization processing and validation supported with our external vendors. |

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e