Application

Introducer Sheaths

Introducer sheaths are intended to provide a stable and controlled entry point for catheters, guidewires, or other medical instruments into blood vessels or other body structures. They are critical in ensuring procedural success by providing a secure and consistent access point while reducing risks of vessel trauma or device contamination.

TE Connectivity (TE) manufactures a diverse range of introducer sheaths for various applications, including access to structural heart valves, electrophysiology ablation catheters, and aortic stent grafts. With our expertise in passive reinforced, deflectable, and steerable shafts, and a streamlined supply chain for metals and polymer components, we can partner with you to deliver efficient, optimized solutions for your introducer sheath requirements.

Configurations

Braided / coiled reinforcement

TE produces introducer sheaths with application-specific designs, incorporating braided, coiled, and combination constructions of reinforced shafts to deliver the strength and flexibility needed to access treatment locations within the body.

Passive, pre-curved, & steerable shaft

TE offers introducer sheaths with tailored shaft designs, including passive, pre-curved, or steerable options to meet your specific application needs. Our steerable shafts are designed for precise steering in single or multiple directions, utilizing a pull wire and pull ring system for enhanced control and flexibility. For improved access to target anatomy, our fixed curve shafts are shaped to ensure optimal maneuverability and ease of use.

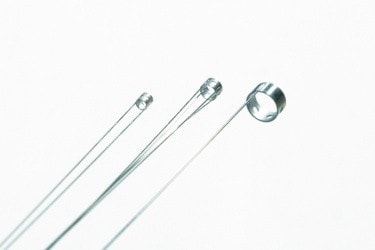

Dilators

TE offers dilators expertly designed for use with introducer sheaths. Featuring purpose-engineered polymer shafts with tapered tips and integrated hubs, these dilators are designed to efficiently expand the vessel aperture, ensuring smooth and reliable insertion of a delivery or treatment sheath.

Hemostasis valves

TE offers introducer sheaths that can be equipped with a hemostasis valve featuring either a mechanical or pressure-activated seal design. This valve ensures smooth passage of dilators and treatment/delivery devices, all while effectively minimizing blood loss during the procedure.

Catheter Manufacturing Capabilities

Catheter Manufacturing Capabilities

| Capabilities | Description (what & how) |

|---|---|

| Liner Stretching | Stretch PTFE liner on mandrel |

| Braiding/Coiling | Braid over mandrel or over lumen; precision needed for torquibility and kink resistance |

| Annealing/Termination | Heat treatment and braid wire termination to ensure smooth transition and no exposure or unravelling of braid wire. |

| Extrusions | Thermoplastic, heat shrink, PTFE (Learn more) |

| Pull-wire Assemblies | Ring welded to wires to enable the steering function in the catheter. (Learn more) |

| Assembly | Assembly of liner jackets or metal consent |

| Reflow/Bonding |

Fusing of liner jackets through ovens and bonding of pull wires mandrels |

| Mandrel Pulling | Removal of the support mandrel used to manufacture the product at the end of the manufacturing process. |

| Cut to Length | Ensuring smooth and clean cuts with good surface finish. |

| RF Tipping | Radio Frequency technology for formation of atraumatic distal tips. |

| Inspection and Testing | Final inspection outside; borescope inspection and testing |

| Packing and Labeling | Packaging and labelling processes for bulk non-sterile and sterile finished goods in compliance with industry standards. |

| Drilling, Punching, and Skiving | Mechanical processes for component and device manufacture. |

| Simulation | Predictive Engineering and Simulation team can perform Structural, flow, thermal, mold flow, light / optics, additive manufacturing and extrusion simulations. |

| Wire-based (coax, electrical) | Cable designs that enable high speed transmission of imaging data, while incorporating various functionalities such as illumination and electrical transmission into a flexible and reliable product component (Learn more) |

| Fine Wire Termination | Integrating copper and fiber connectivity into our cables, producing highly flexible, yet rugged cables for the operating room. (Learn more) |

| Sterilization | Sterilization processing and validation supported with our external vendors. |

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e