Application

Enabling Power & Intelligence at the Heart of an xEV

Connectivity solutions that make EV batteries and fuel cells safer, more efficient, and longer-lasting.

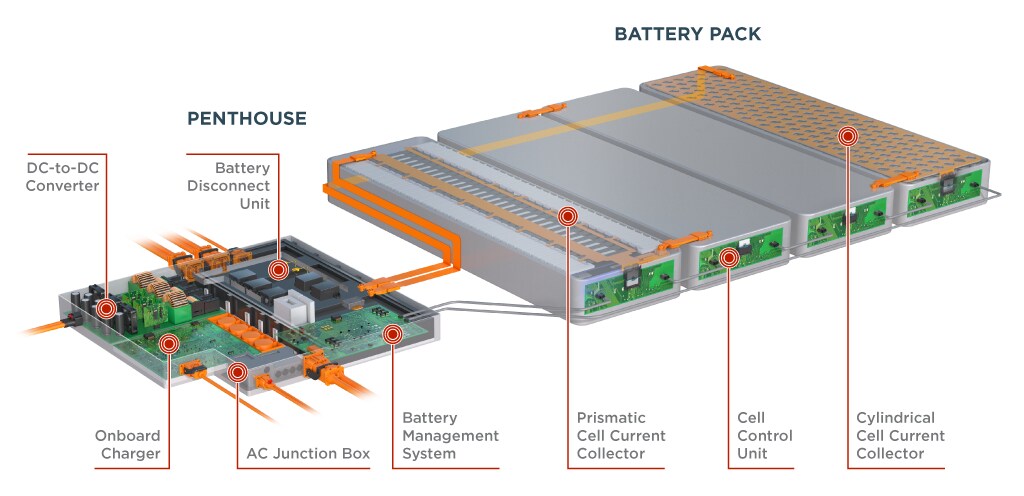

Modern xEV batteries and fuel cells are no longer just energy storage devices. They are intelligent, multifunctional systems that orchestrate power distribution, safety, and communications across the entire vehicle. Housed inside a sealed battery enclosure is a growing number of high-voltage and low-voltage components that collectively manage energy flow, support vehicle systems, enable safe operation, and optimize battery performance throughout its lifespan.

TE Connectivity provides the specialized interconnect solutions for every layer of the battery, from cell-to-cell connectivity and module-to-module energy transfer to miniaturized electronic and electrical interfaces that enable advanced control. Our portfolio enables precise control, accurate power delivery, and scalable integration across the full spectrum of battery applications.

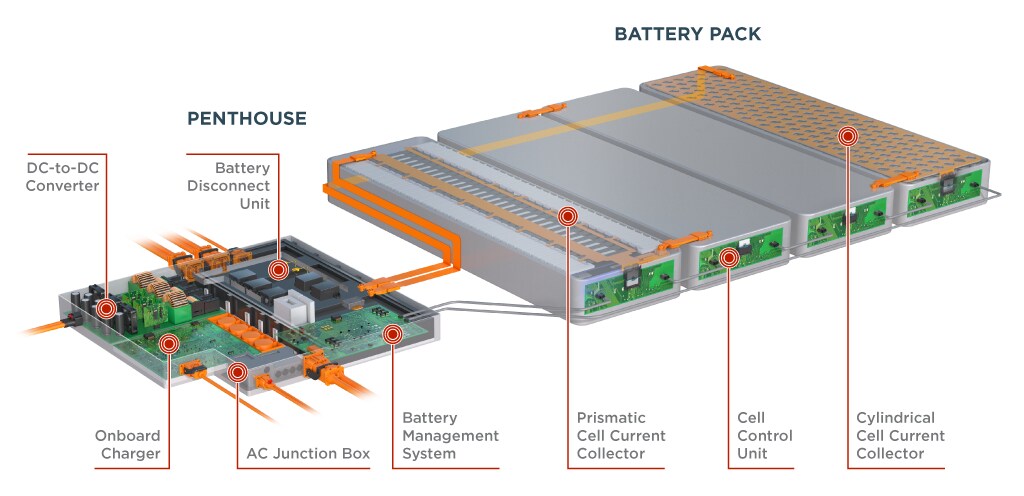

Explore the xEV Battery Pack Components

The battery pack integrates a variety of subsystems that manage high-voltage switching, charging, and vehicle-level power conversion. The sections below outline these functional blocks and the TE solutions that support them.

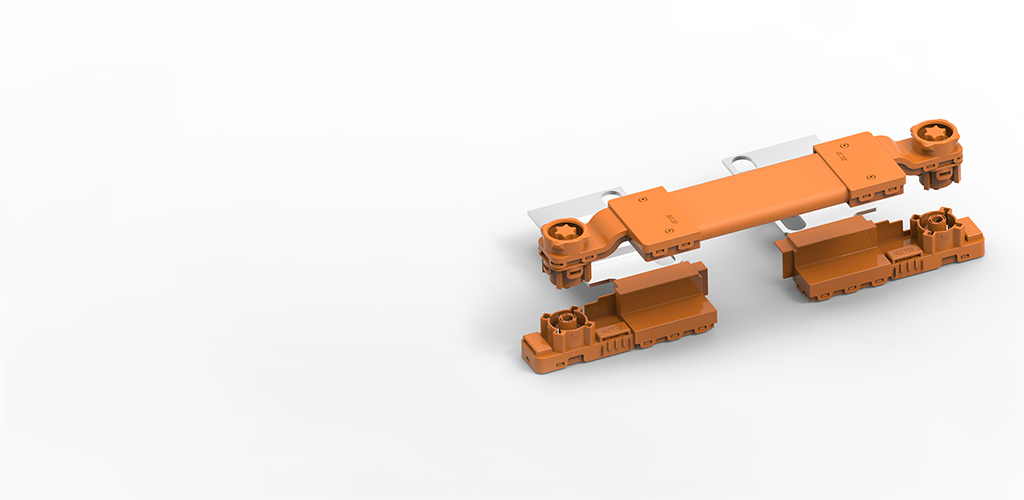

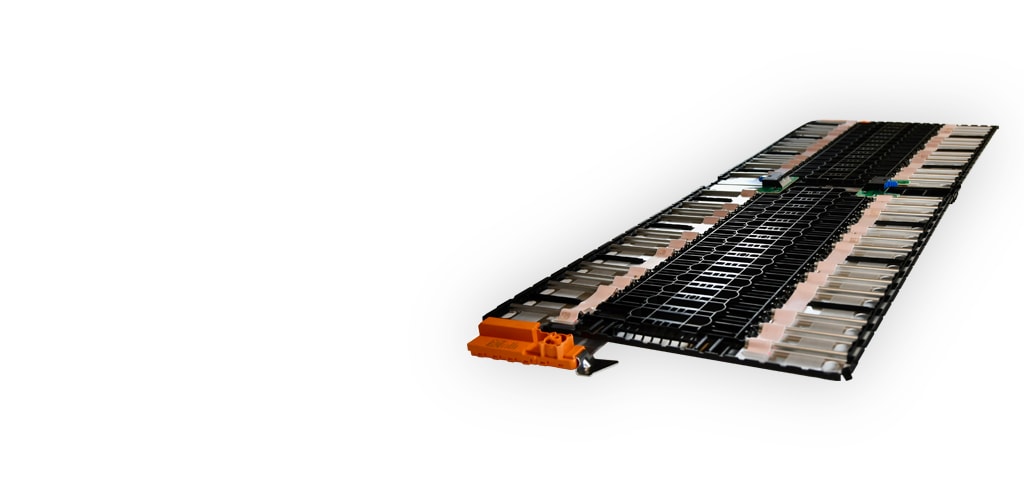

1. Core Electrical Architecture: Cells & Modules

Every xEV battery pack is composed of hundreds of cells, often arranged into modules, which are then assembled into the full pack. The internal electrical architecture requires highly reliable, compact, and manufacturable interconnect solutions to collect and carry current between the cells, between the modules, and ultimately to the battery’s control box and distribution systems.

Recommended TE Solutions:

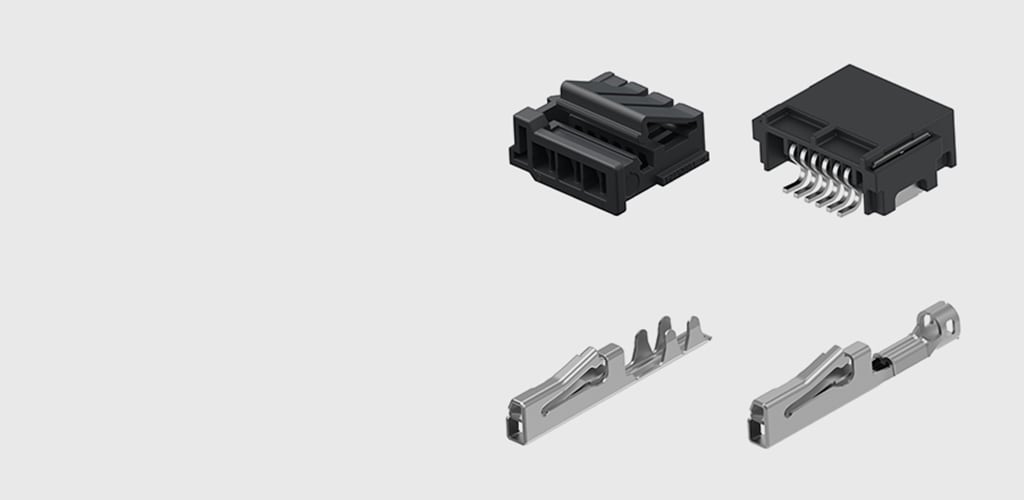

2. Battery Management System (BMS)

The BMS monitors and controls every aspect of the battery pack, from state-of-charge and thermal balancing to system diagnostics and fault detection. It is the digital control center that monitors overall battery health over time. Typical battery management systems include up to 20 PCB-level connectors with 5 to 8 power contacts for intra-system routing.

TE's Inside Device Connectivity Portfolio supports the internal architecture of BMS systems, enabling compact, high-density signal and low-voltage power connections between PCBs. These are critical for linking mother and daughter control boards or managing communication between sensors and controllers.

Recommended TE Solutions:

TE's Inside Device Connectivity Solutions

- Board-to-Board: ERNI SMC Connectors

- Wire-to-Board: PicoMQS, NanoMQS, Dynamic 1000, ERNI

MaxiBridge, MQS High-Voltage Sensing, ERNI Voltron 1000 - Flex-to-Board: ZIF-LINE connectors, ERNI SMC FPC/FFC

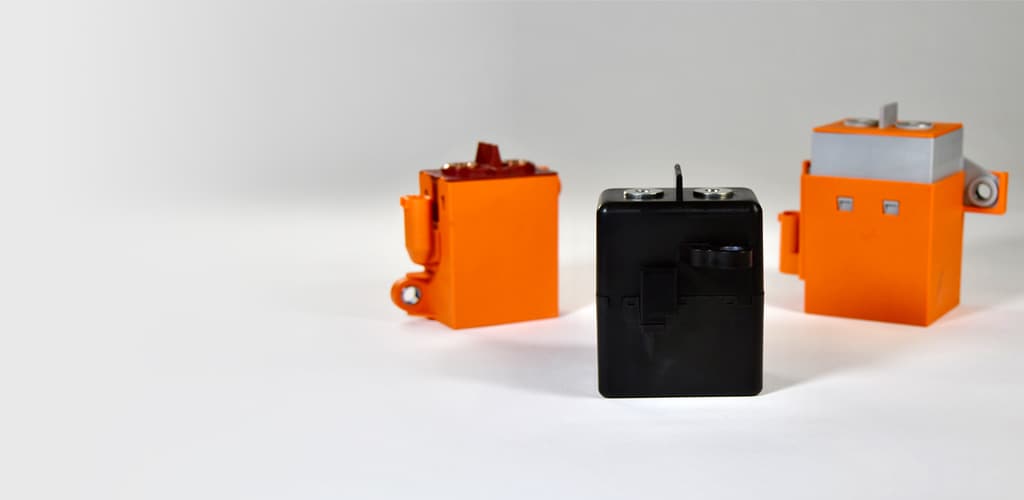

3. Battery Disconnect Unit (BDU) & High-Voltage Switching

The BDU manages safe disconnection and reconnection of the battery during different operational modes. It itegrates contactors, fuses, and sensors that isolate the battery pack during service or fault events.

Recommended TE Solutions:

4. DC-to-DC Converter

The DC-to-DC converter converts high-voltage (400 V or more) DC battery power to lower voltages (either 12 V, 24 V, or 48 V) to support traditional vehicle systems, ECUs, and auxiliary loads.

Recommended TE Solutions:

TE's Inside Device Connectivity Solutions

- Board-to-Board: ERNI SMC Connectors

- Wire-to-Board: PicoMQS, NanoMQS, Dynamic 1000, ERNI

- Flex-to-Board: ZIF-LINE connectors, ERNI SMC FPC/FFC

- Wire-to-Wire: NanoMQS, MQS

5. Onboard Charger (OBC)

The OBC converts incoming AC power from a charging inlet to high-voltage DC for storage in the battery while charging at home or at work using a plug-in system.

Recommended TE Solutions:

TE's Inside Device Connectivity Solutions

- Board-to-Board: ERNI SMC Connectors

- Wire-to-Board: PicoMQS, NanoMQS, Dynamic 1000, ERNI

- Flex-to-Board: ZIF-LINE connectors, ERNI SMC FPC/FFC

6. AC Junction Box & Power Distribution

The AC junction box facilitates AC power distribution throughout the vehicle, including powering in-cabin electrical outlets and optional bidirectional charging (V2L, V2G).

Recommended TE Solutions:

- HVA 280, HVA 280 PRO, HVA 630 Interconnection Systems

- VOLINSU Heat-Shrink Tubing

Why Work with TE Connectivity?

- We support global xEV programs with a network of manufacturing facilities and engineering centers across the Americas, Europe, India, and APAC.

- Our 2,500+ automotive engineers and scientists specialize in connector design, materials science, signal integrity, application-specific customization, and high-volume manufacturability.

Explore More

Application

Enabling Power & Intelligence at the Heart of an xEV

Connectivity solutions that make EV batteries and fuel cells safer, more efficient, and longer-lasting.

Modern xEV batteries and fuel cells are no longer just energy storage devices. They are intelligent, multifunctional systems that orchestrate power distribution, safety, and communications across the entire vehicle. Housed inside a sealed battery enclosure is a growing number of high-voltage and low-voltage components that collectively manage energy flow, support vehicle systems, enable safe operation, and optimize battery performance throughout its lifespan.

TE Connectivity provides the specialized interconnect solutions for every layer of the battery, from cell-to-cell connectivity and module-to-module energy transfer to miniaturized electronic and electrical interfaces that enable advanced control. Our portfolio enables precise control, accurate power delivery, and scalable integration across the full spectrum of battery applications.

Explore the xEV Battery Pack Components

The battery pack integrates a variety of subsystems that manage high-voltage switching, charging, and vehicle-level power conversion. The sections below outline these functional blocks and the TE solutions that support them.

1. Core Electrical Architecture: Cells & Modules

Every xEV battery pack is composed of hundreds of cells, often arranged into modules, which are then assembled into the full pack. The internal electrical architecture requires highly reliable, compact, and manufacturable interconnect solutions to collect and carry current between the cells, between the modules, and ultimately to the battery’s control box and distribution systems.

Recommended TE Solutions:

2. Battery Management System (BMS)

The BMS monitors and controls every aspect of the battery pack, from state-of-charge and thermal balancing to system diagnostics and fault detection. It is the digital control center that monitors overall battery health over time. Typical battery management systems include up to 20 PCB-level connectors with 5 to 8 power contacts for intra-system routing.

TE's Inside Device Connectivity Portfolio supports the internal architecture of BMS systems, enabling compact, high-density signal and low-voltage power connections between PCBs. These are critical for linking mother and daughter control boards or managing communication between sensors and controllers.

Recommended TE Solutions:

TE's Inside Device Connectivity Solutions

- Board-to-Board: ERNI SMC Connectors

- Wire-to-Board: PicoMQS, NanoMQS, Dynamic 1000, ERNI

MaxiBridge, MQS High-Voltage Sensing, ERNI Voltron 1000 - Flex-to-Board: ZIF-LINE connectors, ERNI SMC FPC/FFC

3. Battery Disconnect Unit (BDU) & High-Voltage Switching

The BDU manages safe disconnection and reconnection of the battery during different operational modes. It itegrates contactors, fuses, and sensors that isolate the battery pack during service or fault events.

Recommended TE Solutions:

4. DC-to-DC Converter

The DC-to-DC converter converts high-voltage (400 V or more) DC battery power to lower voltages (either 12 V, 24 V, or 48 V) to support traditional vehicle systems, ECUs, and auxiliary loads.

Recommended TE Solutions:

TE's Inside Device Connectivity Solutions

- Board-to-Board: ERNI SMC Connectors

- Wire-to-Board: PicoMQS, NanoMQS, Dynamic 1000, ERNI

- Flex-to-Board: ZIF-LINE connectors, ERNI SMC FPC/FFC

- Wire-to-Wire: NanoMQS, MQS

5. Onboard Charger (OBC)

The OBC converts incoming AC power from a charging inlet to high-voltage DC for storage in the battery while charging at home or at work using a plug-in system.

Recommended TE Solutions:

TE's Inside Device Connectivity Solutions

- Board-to-Board: ERNI SMC Connectors

- Wire-to-Board: PicoMQS, NanoMQS, Dynamic 1000, ERNI

- Flex-to-Board: ZIF-LINE connectors, ERNI SMC FPC/FFC

6. AC Junction Box & Power Distribution

The AC junction box facilitates AC power distribution throughout the vehicle, including powering in-cabin electrical outlets and optional bidirectional charging (V2L, V2G).

Recommended TE Solutions:

- HVA 280, HVA 280 PRO, HVA 630 Interconnection Systems

- VOLINSU Heat-Shrink Tubing

Why Work with TE Connectivity?

- We support global xEV programs with a network of manufacturing facilities and engineering centers across the Americas, Europe, India, and APAC.

- Our 2,500+ automotive engineers and scientists specialize in connector design, materials science, signal integrity, application-specific customization, and high-volume manufacturability.