Cell-to-Cell (C2C) Connectivity

Delivering scalable, customizable connectivity for tomorrow's EV battery architectures

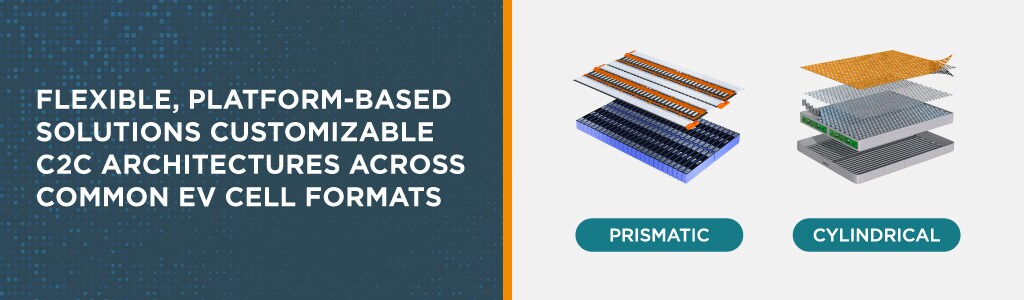

Cell-to-cell (C2C) connectivity in EV batteries presents a range of challenges due to the diversity of cell shapes, sizes, and evolving chemistries. Each battery design brings unique layout, performance, and safety requirements, making one-size-fits-all solutions impractical.

Automakers must also navigate complex assembly processes, tight packaging constraints, and the need for reliable thermal and electrical performance. These factors, combined with increasing demands for cost -efficiency and scalability, make developing robust, manufacturable C2C systems a highly specialized and engineering-intensive task.

At TE Connectivity (TE), we collaborate with leading electric vehicle (EV) manufacturers and battery pack developers to design and manufacture next-generation C2C connectivity solutions. From early-stage design to full-scale production, we bring deep engineering, simulation, and process expertise for cylindrical and prismatic cell formats.

Our global capabilities span research, prototyping, and automated assembly, enabling flexible, cost-efficient system architectures. Whether you’re developing cell-to-pack designs or targeting optimized thermal, sensing, or weight outcomes, TE can help you move from concept to production faster and with greater confidence.

Key Benefits

C2C Connectivity

- End-to-end support: concept, simulation, prototyping, and global manufacturing under one roof

- Customizable platforms: modular C2C designs for all major battery formats

- Integrated systems: current collectors, sense lines, and battery management system connectivity designed to work as one

- Scalable production: clean-room and automated lines in Hungary, Germany, and China

- Cost & weight optimization: streamlined designs that eliminate non-value components

- Proven success: in series production for major OEM battery platforms

- Ongoing R&D: specializing in flexible, additive, and hybrid sense line technologies, thermal event protection, and tolerance compensation

- Automation-ready: our solutions are designed to be compatible with automated assembly and high-volume production target

Reasons to Work with TE

- Full lifecycle partner — we offer end-to-end support from concept through production with global design, prototyping, and manufacturing capabilities.

- Engineering-driven innovation — deep expertise in materials science, simulation, and automation enables optimized, manufacturable designs.

- Aligned with EV battery trends — our solutions address cost, weight, thermal management, and evolving battery formats like cell-to-pack and cell-to-chassis.

e

e

e

e

e

e