Speed, Reliability, and Low Per-line Cost

FASTON tabs and receptacles comprise a family of quick connect terminals that offer high processing rate, low applied cost, and consistent contact reliability. The family includes straight and flag quick disconnect receptacles, wire crimp tabs, printed circuit board (PCB) tabs, and board mount tabs. Terminals are available with numerous optional features, including insulated Ultra-Fast and Ultra-Pod FASTON terminals, low insertion force (LIF) Standard FASTON receptacles, compact mini FASTON terminals, and high temperature resistant nickel-plated steel terminals. FASTON products are grouped into series based on tab width, ranging from .110in for the smallest “110 series” to .312in for the largest “312 series”.

Product Features

| Tab Width (in.) | .110, .125, .187, .205, .250, .312 |

Orientations |

Straight, Left flag, Right flag, Piggyback |

| Tab Thickness (in.) |

.012-.032 |

Crimp Types |

F-crimp, Tab-lock, C-crimp, 2D crimp |

| Wire Size (AWG) |

26-8 | Materials / Plating |

Base: Brass, Phos. Bronze, Steel Plating: Tin, Pre-tin, Silver, Nickel |

| Max Continuous Current (A) |

24 | Pre-insulation Available |

Yes |

| Max Operating Temperature (oC) |

Standard: 110 High-temp: 250 |

Agency Approval(s) |

UL, VDE, CSA |

| Receptacle to Tab Mating Force (N) |

15-80 | Insulation Flammability Ratings |

UL 94 V-0 & V-2 |

Featured Products

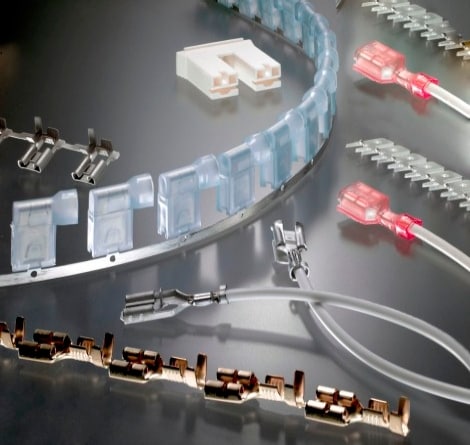

FASTON Receptacle, Tabs, & Housings

FASTON uninsulated terminals—including receptacles and tabs offer high-speed, reliable connections for demanding applications. Receptacles come in straight, right-angle, and combo styles, supporting 8–30 AWG wires and sizes from .110 to .312. Tabs include weld-type, stud-mounted, crimp, and test options. Made from brass, phosphor bronze, or steel with tin, silver, or nickel plating, all components meet UL 310 and CSA C22.2 standards for commercial and industrial use.

Ultra-Fast FASTON Receptacles and Tabs

Ultra-Fast FASTON receptacles and tabs feature fully insulated, closed barrel crimp designs for secure, high-performance connections. The user-friendly shape ensures easy mating, while .187 and .250 series receptacles offer low resistance via a two-stage roll and cantilever dimple. Available in straight, flag receptacles, and tab styles.

Ultra-Pod FASTON Pre-insulated Terminals

Fully insulated FASTON receptacles and tabs featuring an F-crimp terminal that is crimped and insulated with a single stroke of the press and applicator. It enables fast, one-step wire-to-wire connections with built-in insulation for up to 600V protection. The integrated plastic carrier supports bench and automated equipment, eliminating secondary insulation steps. Featuring low insertion force (LIF) for easier tab insertion and reduced fatigue, they’re available in various materials to meet safety and electrical needs.

PIDG FASTON Receptacles & Tabs

Engineered for high reliability, PIDG FASTON terminals feature a tin-plated brass body, copper sleeve, and durable insulation for consistent crimping. TE’s precision compression crimping ensures contamination-free, shock-resistant terminations with tensile strength near that of the wire—ideal for demanding circuit applications.

Standard FASTON Terminals

Advanced quick disconnect terminals featuring a robust low insertion force (LIF) design tested to withstand up to six mating cycles. Terminals are available in multiple crimping options, including the innovative 2D crimp that accepts a full range of wire sizes with a single terminal and applicator.

F-Spring Contact Terminals

Terminals with ergonomic features for safe and efficient assembly, including improved retention, insertion, and contact-stability benefits.

4.8 Series FASTON Receptacles for Multi Thickness Tabs

The 4.8 (187) series straight FASTON receptacle terminals are designed to mate with either a 0.5 mm (.020 in) or 0.8 mm (.031 in) thick quick disconnect tab.

250 Series Miniature FASTON Receptacle

Compact straight terminal for space constrained applications. The receptacle mates .250x.032in tabs and supports up to 7A of continuous current.