Application

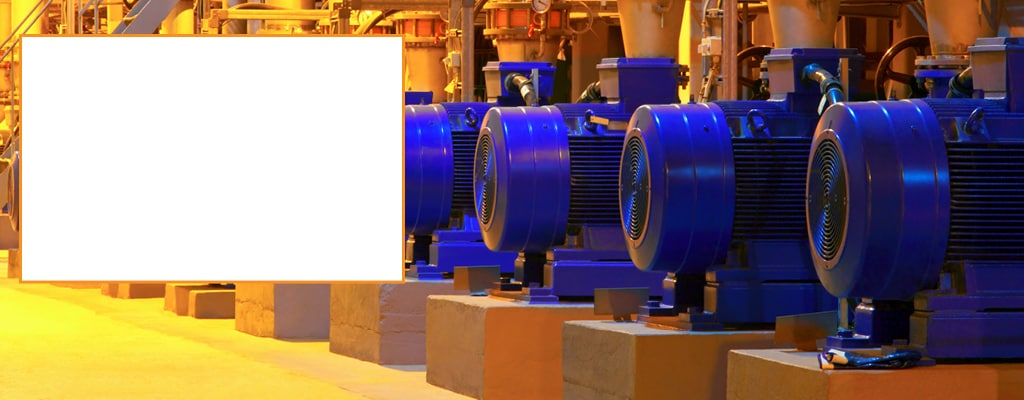

Industrial Sensor Solutions

We manufacture innovative industrial sensors that help customers transform concepts into smart, connected creations.

Industrial sensing covers a broad range of applications and sensor types. Our sensor solutions support industrial machinery, power and utilities, telecom, instrumentation, vending equipment, and security equipment. Our sensor portfolio includes pressure transducers, liquid level sensors, accelerometers, LVDT/RVDT’s, inclinometers, string and linear/rotary potentiometers, load cells, temperature, torque sensors, and a full range of interface electronics. TE designs and manufactures sensors to exacting specifications for the rigors of general industry applications. Our engineers provide support of application-specific, standard and custom requirements, from product concept through manufacturing. Learn about some of the specific industrial applications we support or contact us to discuss your application.

Custom TE Connectivity Sensors

-

Connect With Us

Together with our customers, we are working to solve today's biggest application challenges in new and creative ways. We design custom sensors to our customers' exacting specifications everyday. With a specialized global team and dedicated engineering, we can help you develop custom solutions for your ideas across a broad range of industries and applications.

Application

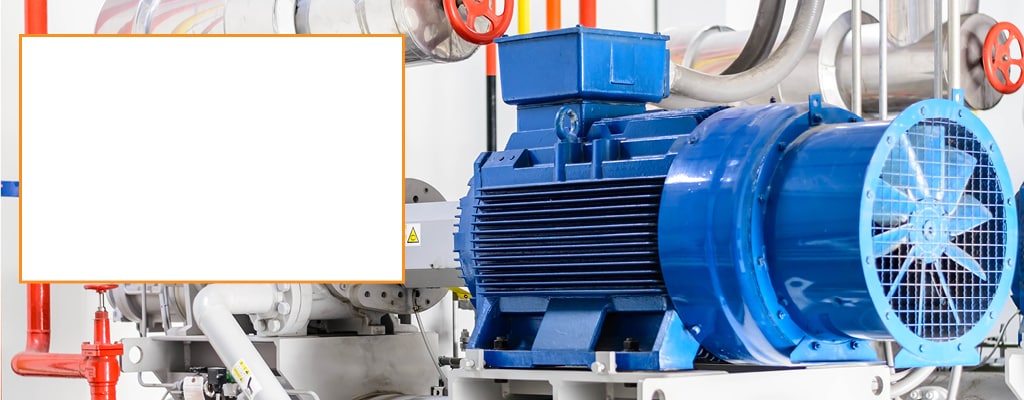

Industrial Sensor Solutions

We manufacture innovative industrial sensors that help customers transform concepts into smart, connected creations.

Industrial sensing covers a broad range of applications and sensor types. Our sensor solutions support industrial machinery, power and utilities, telecom, instrumentation, vending equipment, and security equipment. Our sensor portfolio includes pressure transducers, liquid level sensors, accelerometers, LVDT/RVDT’s, inclinometers, string and linear/rotary potentiometers, load cells, temperature, torque sensors, and a full range of interface electronics. TE designs and manufactures sensors to exacting specifications for the rigors of general industry applications. Our engineers provide support of application-specific, standard and custom requirements, from product concept through manufacturing. Learn about some of the specific industrial applications we support or contact us to discuss your application.

Custom TE Connectivity Sensors

-

Connect With Us

Together with our customers, we are working to solve today's biggest application challenges in new and creative ways. We design custom sensors to our customers' exacting specifications everyday. With a specialized global team and dedicated engineering, we can help you develop custom solutions for your ideas across a broad range of industries and applications.