Industries

Surgery

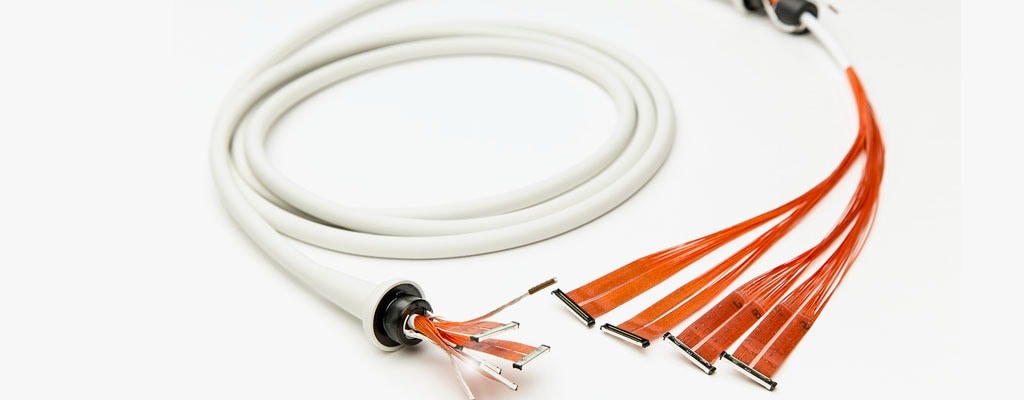

TE has decades of experience developing cables, connectors, metal, sensors and polymer components that provide visual clarity, connectivity and intelligence for surgical devices and systems.

Our surgery solutions enable the connection of the surgical device to the physician and patient, which can help make surgeries safer, more accurate and precise – the physician stays focused on the procedure and not the device.

Working with our customers to co-create surgical devices that deliver:

- Enhanced visual detail and clarity – enabling the physician to plan and perform surgery with more accuracy.

- Connectivity – we integrate devices, adding connectivity solutions that augment accuracy and precision in surgery. Think plug and play devices that self-configure.

- Intelligence – we are helping to make surgery devices and systems smarter. Our components enable devices to sense and respond in real-time, not just turn on or off, enabling the surgeon to perform surgeries with greater precision.

Together, we can enable faster and more cost effective surgeries.

Electrosurgery

TE enables the application of power sources to the device to cut, coagulate and dissect tissue or organs.

Laparoscopy

For medical devices deployed via laparoscopic or keyhole ports, we augment devices for responsive touch and feel.

Robotic Assisted Surgery

From highly engineered tubing, to imaging cables and sensors, we offer solutions throughout the robotic assisted OR.

Technical Expertise

- Developing products that can withstand high pressures, humidity, and variable temperatures, while keeping the signal integrity and avoiding moisture ingress.

- Designing components that’s flexible with your needs, combining high performance, light weight, and ergonomics.

- Extensive knowledge in material science to partner with customers to meet their specifications for sterilization and biocompatibility.

- In-house testing for design validation, sterilization, environmental and other testing to your exact product and regulatory needs. Our experts can also support high speed signal modeling and analysis, flex testing, and thermal modeling and analysis.

- Manufacturing process expertise in: stamping, molding, grinding, laser processing, metallurgy, fine wire management, extrusion, and assembly.

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e