Optimal Grid Reliability

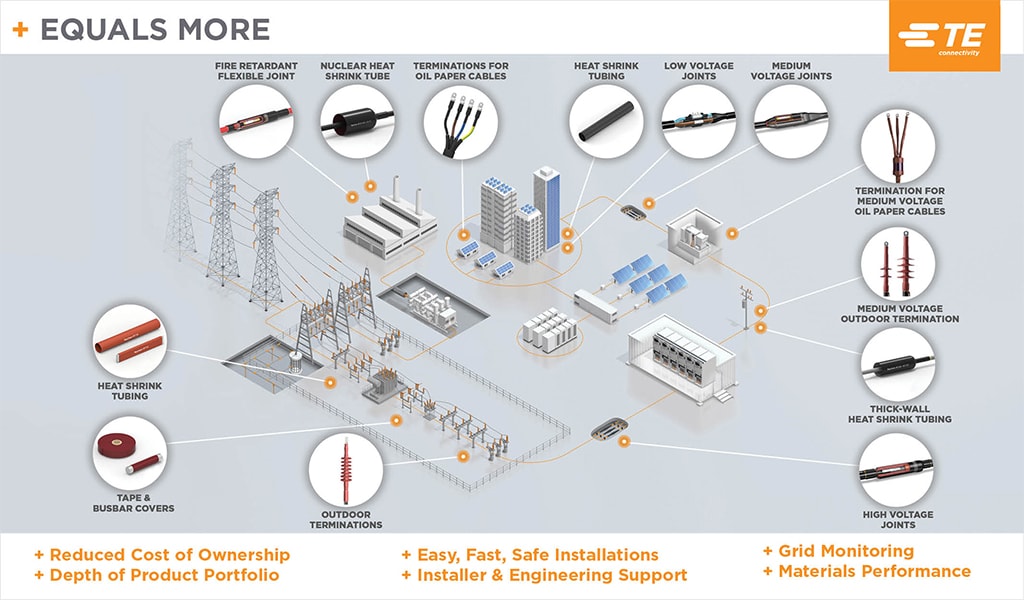

When reliability and total cost of ownership are your number one concerns, you can trust your grid to Raychem Heat Shrink. Critical infrastructures. Remote locations. Design Constraints. Harsh Environments. We've faced and navigated these challenges together to help deliver greater confidence in the reliability and protection of your grid from generation to transmission to distribution to where ever energy is needed.

1st

pioneer of heat shrink technology

358M

(million) kilometers of heat shrink produced by TE since 1980

40+

years of field service without the need for maintenance

The Raychem Difference

For more than 60 years TE Connectivity has developed Raychem heat shrink technology for energy applications. Our heat shrink technology is based on specially-formulated thermoplastic polymer materials, which means we can help optimize the product for your applications. Our products are known for their high quality, reliability, and ability to withstand weathering processes like pollution and contamination, UV-light, salt fog and other harsh environments. TE’s exceptional heat shrink products are the cornerstone of our highly reliable cable accessory product offering from 1 kV up to 123 kV.

Turn up the Heat, Shrink the Worry

For more than 60 years TE Connectivity has developed Raychem heat shrink technology for energy applications. Our heat shrink technology is based on specially-formulated thermoplastic polymer materials, which means we can help optimize the product for your applications.

Install and Forget

Thanks to sophisticated process controls employed during the manufacturing of our heat shrink tapes, tubing, wraparound sleeves, splices and terminations, they will maintain their shape memory off the shelf for decades and perform robustly in the field for more than 40 years after installation. When you partner with TE you are getting more than reliable products. You are benefitting from a proven track record connecting and terminating power to critical infrastructures to last for decades with minimal worry.

Consult

TE experts and a network of authorized distributors can support you wherever you are located and help you select the right solutions.

Design

Collaborate with our engineering team to create a custom solution.

Test

We test custom solutions in our labs and can test the cable you selected to our solution to ensure high performance and reliability.

Train

Our training programs help certified installers realize the full potential of our reliable technology and serve as a valuable asset to your team - and to your network.