0.64mm Automotive Terminals & Connectors

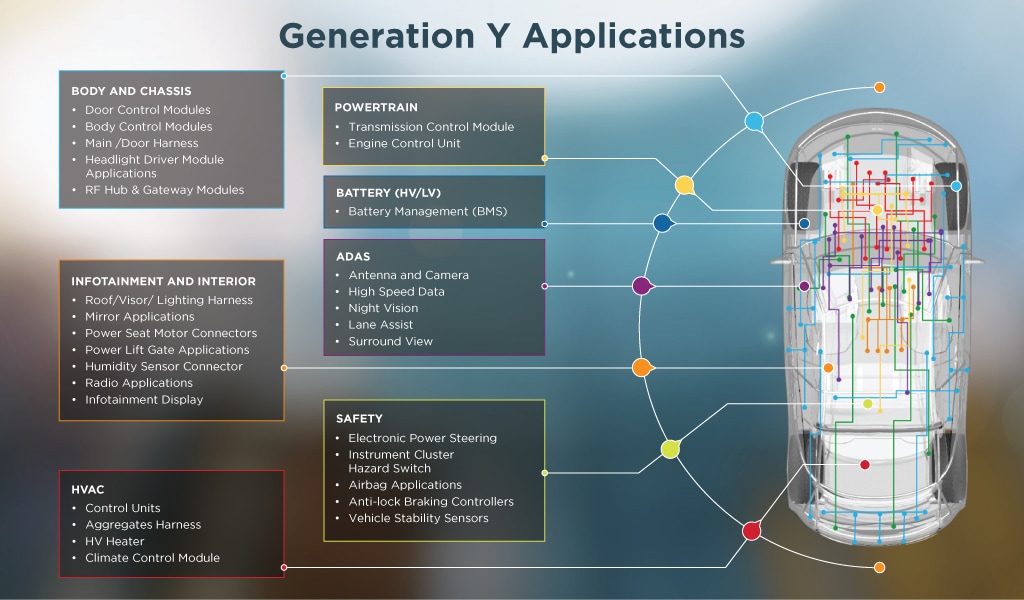

TE Connectivity's (TE) Generation Y portfolio of 0.64mm terminals, connectors, and headers, offers proven compact, low mating force connectivity solutions for a large range of signal applications. These connectors are available in various positions as well as hybrid connector designs.

USCAR

Sealed and unsealed connectors exceed performance requirements of USCAR-2, -20, -21 and -25 connector design and ergonomic standards

0.64

Proven and preferred 0.64mm connector system for North American OEM's

2.2

Lowest centerline pitch for 0.64 connector systems

Generation Y Featured Hybrid Connectors

NEW!! Generation Y 68P Sealed Hybrid Inline Connector

- 65% Less Supply Chain Complexity

- Cost-effective

- Ease of Manufacturing and allows for improved packaging and wire routing

- Reduced Footprint

- Automotive grade robustness including male side pin protection plate

- x44 TE Generation Y .64mm Terminal System

- x2 TE Mate-AX Mini Coax Terminal System

- x10 2.8mm Terminal System

- x12 1.5mm Terminal System

Generation Y Featured Hybrid Connectors

TE Connectivity Hybrid Solutions

- Configurable solutions that integrate data connections Into low-voltage power and signal connectors

- Data Connectivity option to meet customer’s speed and data integrity requirements

- Easier operator assembly and processing time through reduced number of connections

- Reduced cost and supply chain complexity

- Smaller and compact packaging and wire routing – new networking topologies to reduce complexity, cable length, weight and cost

- Familiar interface with customizable options

- Software-driven service-oriented architecture

Features and Benefits

- Sealed and unsealed connectors for use in cabin or engine applications

- Low engagement force contact allows for higher pin count with hand mate while meeting requirements of USCAR-25

- 2.2mm centerline pitch capable to allow greater density to reduce PCB costs

- 0.64 mm/2.8mm hybrid connectors provide power and signal in one package to reduce complexity and cost

- Off-the-shelf or application specific design available.

- Header materials available for IR resistance and lead-free solder processing

- One piece hinge-lock plug housing provides independent secondar locking of female terminal

- Header designs available with thru-hole solder tails, surface mount tabs or press-fit compliant pin terminals

- Header designs available in vertical or right-angle; with or without boardlocks

- Sealed and unsealed connectors exceed performance requirements of USCAR-2, -20, -21and -25 connector design and ergonomic standards

Crimp Quality Starts with World-Class TE Application Tooling

Low Volume Wire Processing

Mid to High Volume Wire Processing

Connect with a Tooling Expert

Creating a quality crimp connection is essential to delivering high performance and reliability in extreme environments. From low to high volume wire processing, TE has you covered with a full range of application tooling and a global field service team. Connect with our product experts today to find the right tool for your Generation Y 0.64mm connector needs.