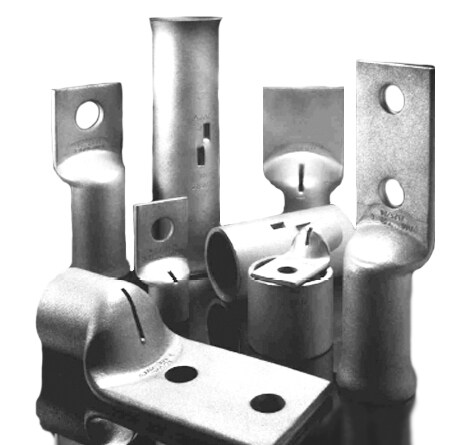

Engineered for Power Generation and Distribution

AMPOWER terminals and splices are made of high quality seamless tubular copper for excellent conductivity. Our special tin plating process inhibits corrosion and provides trouble-free service. A special die stamping process converts the copper tube into a double thickness rectangular tongue with a short strong transfer section. These factors combine with the formulated AMPOWER terminal crimp to produce excellent conductivity and excellent strength. With our compression crimping, TE offers a reliable technology that is completely mechanical and controllable from first to last crimp, eliminating variables common to other crimping methods, such as melting temperatures, flux composition, entrapped gases, or oxidation.

Product Benefits

AMPOWER

- Versatility: Stranded wires when crimped, become almost a homogeneous mass with the AMPOWER terminal or splice barrel

- Strength: AMPOWER terminals have formidable strength and resistance to vibration suitable for their intended use

- Economy: An important part of all AMPOWER products is low installed cost.

- Conductivity: corrosion resistance and temperature rise

- Positive Inspection: AMPOWER terminals and splices are supplied with inspection slots in the barrel

- Broad Wire Size Range: Covering wire sizes from 6 AWG to 1000 MCM (13 to 507 mm2) - for terminals and up to 1500 (760mm2) for splices

Applications

- Rail

- Mass transit

- Power transmission

- Military

- Off-highway

AMPOWER Quick Disconnect

The AMPOWER quick disconnect terminals have been specifically designed for use in the transportation industry since they provide a highly reliable and economic means of terminating large power cables and leads. They are ideally suited for a variety of applications such as motors, generators, transformers, plus numerous other electrical equipment subjected to shock and vibration as well as long continuous periods of operation.