View products below to see detailed pricing

-

Product Listing

Wireless Pressure Transducer

- MEAS

- MEAS M5600

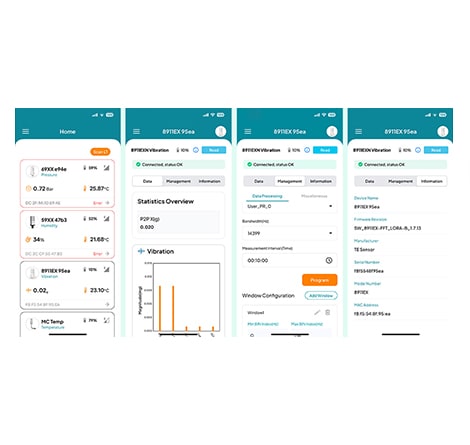

The M5600 series wireless pressure transducer features a high accuracy, 24-bit ADC digital output eliminating hard wiring and provides remote process control and monitoring via Bluetooth® 4.0 wireless communication.

Product Features

-

Pressure Sensor Type : Wireless Pressure Transducer

-

Pressure Type : Compound | Gauge

-

Hazardous Area Approval : None

-

Frequency Band (MHz): 2400

-

Pressure (bar): 10 | 20 | 68.94 | 70 | 200 | 345 | 350 | 500 | 689 | 700 | 1000

-

Pressure (psi): 200 | 300 | 1000 | 3000 | 5000 | 7000 | 7252 | 10000 | 15000