Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

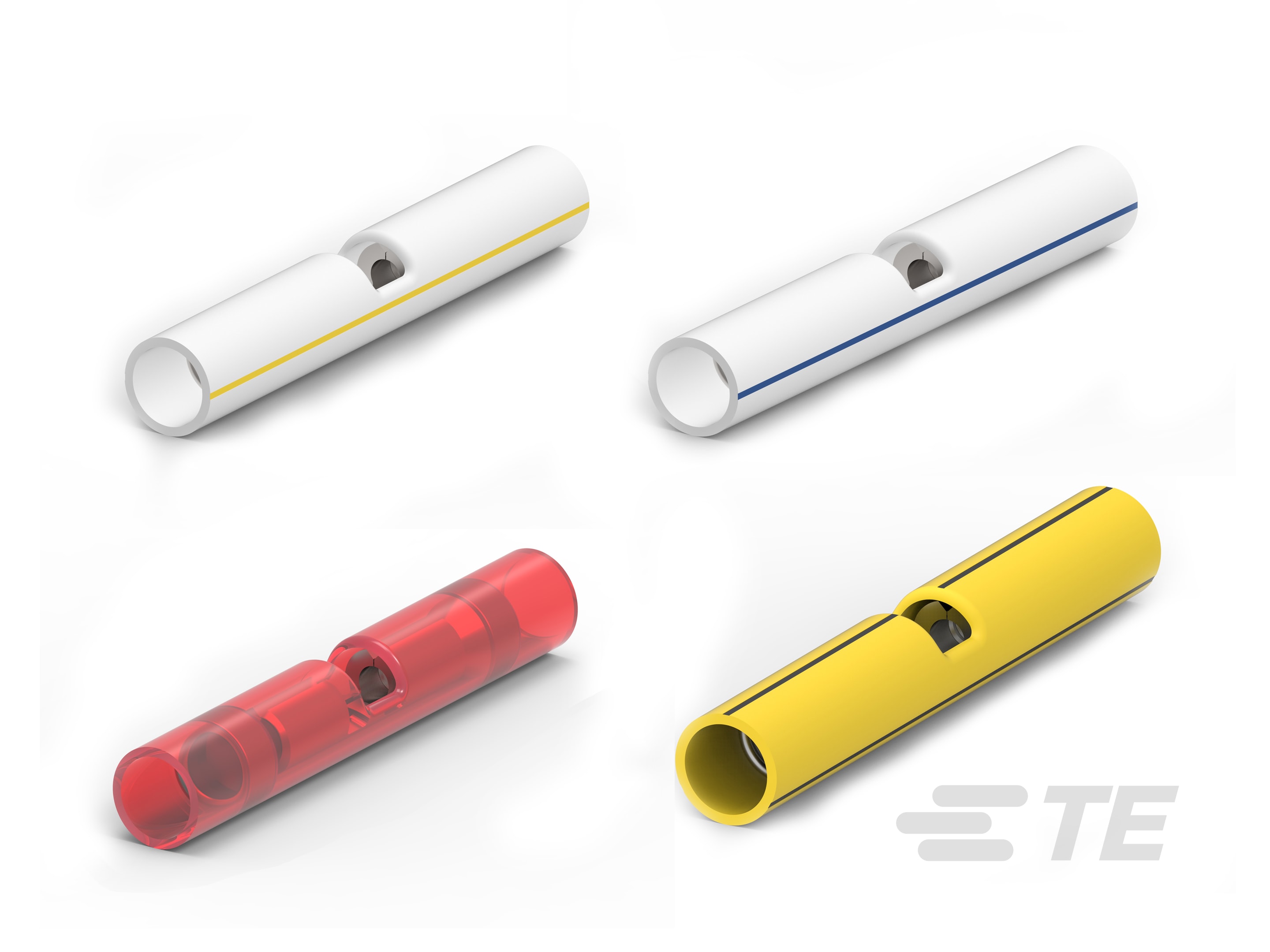

Splice Accessory Type

Splice

-

Splice Type

Butt Splice

-

Sealable

No

-

Compatible With Discrete Wire Type

Stranded

-

Wire Insulation Support Retention Type

Insulation Support

Configuration Features

-

Number of Serrations

8

-

Compatible With Wire & Cable Type

Discrete Wire

Electrical Characteristics

-

Operating Voltage (V)

300

-

Operating Voltage (VAC)

600

Body Features

-

Stripe Color

Black | Red

-

Insulation Support Sleeve Material

Copper

-

Insulation Material

Copper | Nylon | PVF2

-

Product Weight (g)

.411 | .709 | .735 | .855 | 1.48 | 1.489 | 1.61 | 1.619 | 1.934 | 2 | 2.05 | 3.402 | 3.8 | 4.092 | 4.383 | 4.404 | 4.536 | 10

-

Splice Features

Serrated

-

Primary Product Color

Blue - Transluscent | Natural | Red - Translucent | Yellow | Yellow - Translucent

Contact Features

-

Military Part Class

Class I | Class II

-

Terminal Plating Material

Tin | Tin-Lead

-

Contact Base Material

Copper

-

Barrel Type

Closed

Termination Features

-

Termination Method to Wire & Cable

Crimp

Mechanical Attachment

-

Wire Insulation Support

With

Dimensions

-

Recovered Inside Diameter

3.89 mm [ .153 in ]

-

Wire Size (AWG)

12 – 10 | 16 – 14 | 22 – 16 | 22 – 18 | 24 – 20 | 26 – 22

-

Wire Size (mm²)

.12 – .24 | .12 – .4 | .2 – .6 | .26 – .96 | .3 – 1.42 | 1.04 – 2.62 | 1.25 – 2 | 3 – 6

-

Compatible Insulation Diameter Range (mm)

2.08 | 2.09 | 2.54 | 3.18 | 3.81 | 5.59 | 6.35

-

Compatible Insulation Diameter Range (in)

.082 | .1 | .125 | .15 | .22 | .25

-

Barrel Inside Diameter (mm)

.73 | 1.09 | 1.55 | 2.16 | 3.28 | 6.4

-

Barrel Inside Diameter (in)

.029 | .043 | .061 | .085 | .129 | .253

-

Wire Size (kcmil)

.202 – .81 | .238 – .475 | .32 – 1.29 | .509 – 3.26 | 2.05 – 5.18 | 5.18 – 13.1

-

Wire Size (CMA)

202 – 810 | 238 – 475 | 320 – 1290 | 509 – 3260 | 2050 – 5180 | 5180 – 13100

-

Terminal Material Thickness (mm)

.38 | .46 | .51 | .56

-

Terminal Material Thickness (in)

.015 | .018 | .02 | .022

-

Product Length (mm)

22.61 | 26.29 | 32.13 | 32.14 | 41.91 | 42.06 | 42.07

-

Product Length (in)

.22 | .87 | .89 | 1.035 | 1.265 | 1.65 | 1.656

Usage Conditions

-

Insulation Option

Fully Insulated

Operation/Application

-

Compatible With Wire Base Material

Copper

Industry Standards

-

Government Qualified Splice

No | Yes

Packaging Features

-

Packaging Quantity

1 | 25 | 50 | 100 | 500 | 1000 | 1500 | 2500 | 4000

-

Packaging Method

Loose Piece | Tape Mounted