Learn how sensors can be used in predictive maintenance and the added value of recognizing sensors as key components of condition monitoring applications. These industrial sensors help predict machine failures, increase productivity, lower maintenance costs, and improve worker safety in harsh environments.

Application

Sensors in Industrial Condition Monitoring

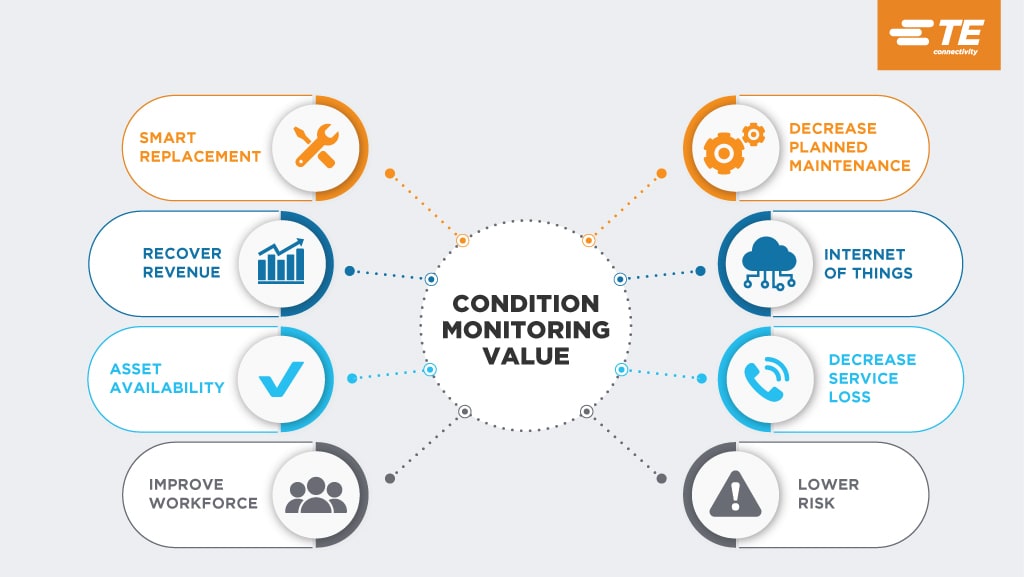

Sensors in condition monitoring applications can help anticipate machine failures, increase productivity, lower maintenance costs, and improve worker safety.

While condition monitoring has been around for years, it is evolving with the Internet of Things (IoT). This growth of IoT, and its advancing ecosystem which supports continuous monitoring in all factory assets, has affected condition monitoring practices and has contributed to evolving predictive maintenance operations. Sensors are now being manufactured to include the requirements demanded by this IoT ecosystem. The latest sensor developments are being influenced by IoT trends such as miniaturization, digitization, sensor fusion, low power and wireless technologies while being packaged for harsh environments. As a result, sensors are progressing to enable continuous condition monitoring by collecting data which facilitates intelligent decisions via machine learning or artificial intelligence (AI). Vibration, pressure, position, speed, fluid property, temperature and humidity sensors all play a critical role within industrial condition monitoring applications. These industrial sensors help reduce downtime by predicting machine failures, increasing productivity, lowering maintenance costs, and improving worker safety.

Industrial condition monitoring sensors historically have been used for heavy, high-end machinery such as windmills, industrial pumps, compressors, and HVAC systems. However, with the shift in IoT and increased automation practices, there is a need for adding condition monitoring sensors onto smaller systems such as machine spindles, conveyor belts, sorting tables, and machine tools which require better predictive maintenance. Reducing machine downtime in these industrial applications is a critical consideration in terms of customer experience and profitability. Therefore, the value of implementing condition monitoring and preventive maintenance practices include many benefits which would not be realized without the use of accurate, reliable sensors. With the proper sensor to measure the needed data, condition monitoring could be accomplished within any industrial application and predictive maintenance can take place to confirm that operations can stay up and running when needed.

Predictive Maintenance

While scheduled maintenance can go a long way towards ensuring equipment health, it may not be the most efficient or cost-effective method of servicing a system. Replacing a part on a scheduled timeframe does offer a predictable downtime, but it doesn’t always use the full lifespan of the part. Depending on the complexity of the system and the scarcity of the materials used, replacing a part too early can create unnecessary cost burden and excess environmental waste. Predictive maintenance, a subset of condition monitoring, focuses on determining when maintenance needs to be performed on industrial equipment and machinery. It enables uptime for manufacturing factories and allows for continuous development of goods to confirm positive customer experiences and profitability.

Sensors provide the technologies needed to detect and flag the possible failure characteristics. Pressure sensors can monitor filtration, vibration sensors can monitor wear, and temperature sensors can monitor friction. Sensors can create intelligent warning systems that alert when parts have reached the end of their useful life. Only replace what you need, when you need.

Because evidence of failure may be extremely subtle or occur only intermittently, constant monitoring with industrial automation sensors is key to capturing it. When fed into a computerized maintenance management system (CMMS), this data becomes a powerful forecasting tool to drive just-in-time maintenance workflows and supply chains. As data grows over time, predictive maintenance analysis becomes more accurate.

While condition monitoring has been around for years, it is evolving with the Internet of Things (IoT). Watch this webinar to discover how IoT is evolving, how condition monitoring sensors are enabling this shift, and the value of recognizing sensors as key components of condition monitoring applications.

Factories are becoming more autonomous and require sensors to monitor equipment on the factory. Watch this webinar to learn how sensors are capturing critical data for performance analytics, improved efficiency, lower costs, and better equipment utilization.

TE's 65xxN & 69xxN series wireless pressure sensors bring practical innovation to industrial monitoring. Engineered with LoRaWAN® and Bluetooth® technologies, these compact sensors fit seamlessly into various environments, from tight spaces to remote infrastructures.

TE's 85x1N & 89x1N series wireless vibration sensors bring great stability and longevity to industrial monitoring. Utilizing both Bluetooth® Low Energy and LoRaWAN® technologies, these compact sensors fit seamlessly into tight spaces and diverse environments.

FREQUENTLY ASKED QUESTIONS

What is industrial condition monitoring?

Condition monitoring is the method of assessing components within industrial equipment to identify any changes that occur within the machinery which typically indicates there is a problem. If there is a significant change detected, this could signal the need for maintenance.

Do sensors enable condition monitoring and predictive maintenance?

Yes, by placing sensors on industrial equipment to monitor performance, identify changes in different parameters, and determine if changes signal a need for equipment maintenance enables the practice of condition monitoring and/or predictive maintenance. Sensors are progressing to facilitate continuous condition monitoring by collecting data which helps in making intelligent decisions via machine learning or artificial intelligence (AI).

The Industrial Internet of Things (IIoT) evolution is driving demand for remote condition monitoring systems in various industries. TE Connectivity offers a range of wireless vibration sensors, enabling convenient and dependable monitoring and analysis of critical equipment from any location and at any time.

LEARN MORE

Industrial Condition Monitoring Sensors

-

The Drive To Go from Wired to Wireless Trend Paper

Learn about the industry drivers behind the trend of wired to wireless in condition-based monitoring of rotating equipment assets.

-

Vibration Sensors for Condition Monitoring White Paper

Learn how vibration sensors are used in condition monitoring applications and how to select the right technology.