Advancing Medical Device Innovation with TE's Precision Coils

TE's medical coils are specialized components designed for medical device applications, including guidewire coils, neurovascular coil delivery, catheter shaft reinforcement, and women’s health devices. We provide an extensive range of off-the-shelf coils for rapid deployment with customizable dimensions, and premium materials.

With 25 years of specialized experience in Medical Coils - we understand the challenges our customers face in medical device manufacturing: extended lead times, economic constraints, and substantial engineering costs. Our advanced coil solutions are designed to address these issues and enhance your production processes. Our rapid prototype coil platform is designed to expedite your product development cycle. By reducing development time and costs, we help you gain a competitive advantage in bringing innovative medical devices quickly to market. Partner with TE Connectivity to elevate your medical device manufacturing and bring your innovative ideas to life.

About our Medical Coils offering

- Expert Collaboration: Our engineering team, with over 25 years of specialized experience, is committed to supporting your product development journey.

- Global Manufacturing Network: With strategic locations in the USA, Ireland, and Costa Rica, we offer efficient production and delivery to meet your needs.

- Scalable Production: From initial prototypes to high-volume manufacturing, our solutions adapt to your requirements with a focus on quality and customization.

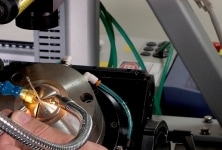

- Precision Manufacturing: Our advanced manufacturing technology is engineered for consistent, high-quality products across all production volumes.

- Rapid Development: Extensive range of off-the-shelf coils for rapid deployment to speed your prototyping requirements.

Materials & Specifications

Materials & Dimensions

Customizable dimensions:

- OD 0.0055" (0.1397 mm) to 0.050" (1.27 mm)

- ID 0.003" (0.0762 mm) to 0.048" (1.2192 mm)

Premium materials:

- Stainless Steel

- Platinum alloys

- Tungsten

- MP35N

- Nitinol

Capabilities

Capabilities

- Tapered and multi-pitch coil designs

- Round and flat wire options

- High-precision coil cutting

- Extended coil lengths up to 120" (304.8 cm)

Benefits

Precision-Wound Construction:

For uniformity and consistent performance, that is crucial for your medical devices.

Flexibility and Durability:

Utilizes biocompatible alloys to enhance flexibility and minimize risk of device failure.

Enhanced Visualization:

Optional radiopaque markers facilitate precise tip placement during therapeutic procedures.

Tailored for Medical Device Applications

Our coils are specifically engineered for:

- Neurovascular intervention devices

- Cardiovascular intervention devices

- Endovascular intervention devices

- Structural heart intervention devices

- Electrophysiology intervention devices

- Peripheral intervention devices

Manufacturing Locations

Technical Resources

Frequently Asked Questions

FAQs

Q: Can you customize wire diameter, pitch, turn count, or length?

A: Yes, our coil winding process is highly configurable. We support wire diameters from 0.0005” (~0.0127 mm) up to 0.008” (~0.2 mm), with precise control overturn count, pitch, and coil length. We work closely with you to match dimensionaland mechanical specs.

Q: Are your processes ISO 13485 certified or FDA audited?

A: Yes, TE Connectivity operates under ISO 13485:2016 and FDA-audited quality systems for medical manufacturing.

Q: Do you support rapid prototyping?

A: Yes. We have fast-track engineering teams to support early-stage development and feasibility builds, with short lead times and iterative design feedback.

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e