-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples (with Business email address)

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

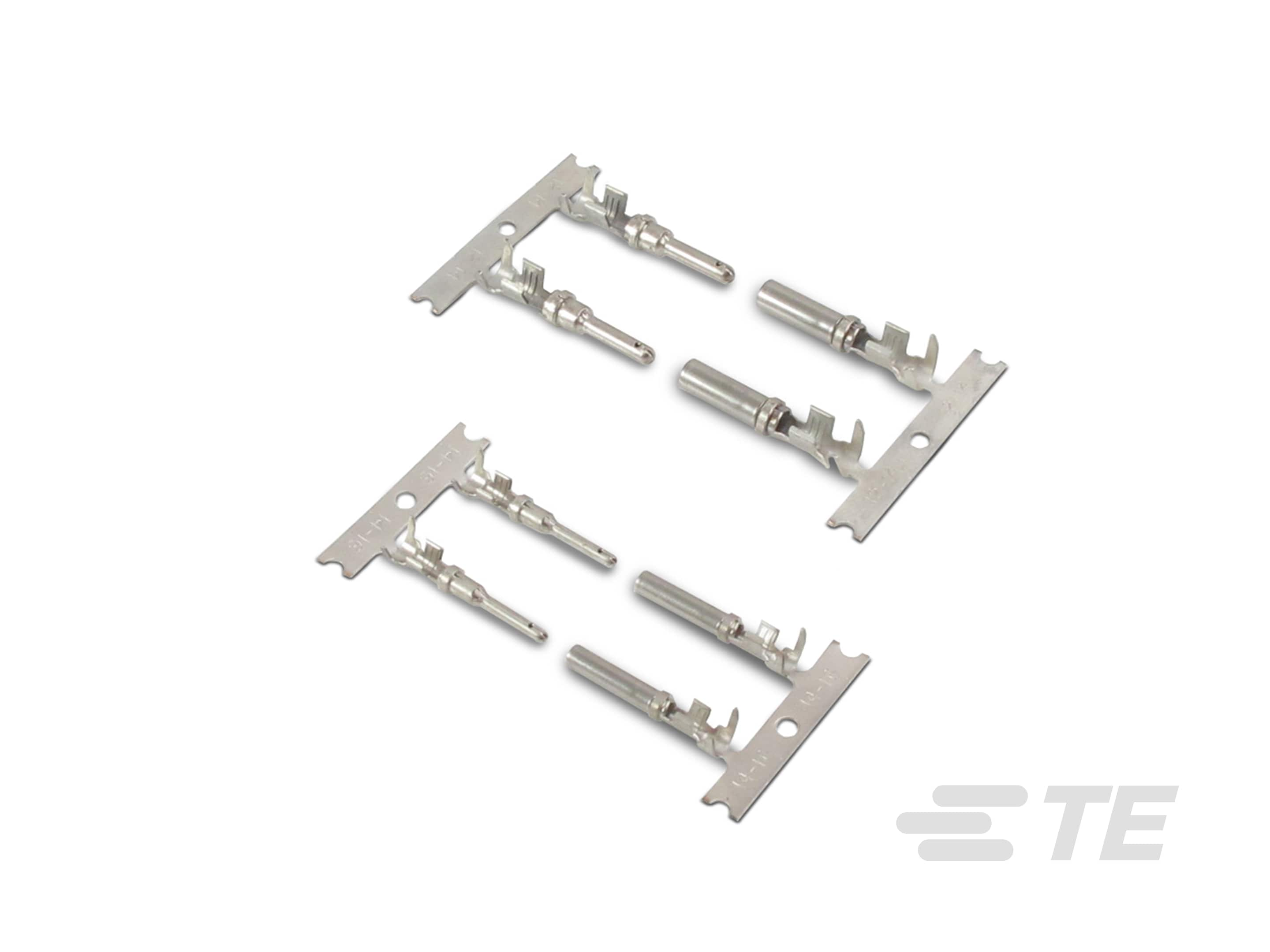

DEUTSCH Connector Stamped and Formed Contacts - Reel

- DEUTSCH

- DEUTSCH Common Contact

Product Features

-

Terminal Type : Pin | Socket

-

Wire Size (AWG): 10 | 14 – 12 | 16 – 12 | 16 – 14 | 18 – 14 | 20 – 16 | 22 – 16

-

Wire Size (mm²): .35 – 1.5 | .5 – 1 | .517 – 1.3 | .75 – 2 | .823 – 2.08 | 1. – 2.5 | 2 – 4 | 4 – 6

-

Interface Plating : Gold (Au) | Nickel (Ni) | Palladium Nickel Gold (PdNiAu) | Tin (Sn)

-

Primary Locking Feature : Integrated in Housing | On the Terminal

Available from

New Datasheet (English)

DEUTSCH Stamped & Formed Contacts

Access the latest DEUTSCH Stamped & Formed Contacts datasheet for detailed technical specifications, wire compatibility, plating options, and associated tooling. This document covers stamped & formed contact series used across our DEUTSCH portfolio for commercial vehicle and industrial transportation systems.

Key Benefits:

DEUTSCH Connector Stamped and Formed Contacts - Reel

Cost-Effective Termination

Stamped and formed construction provides a lower-cost alternative to solid contacts for large-volume wiring applications.

Wide Wire Size Compatibility

Accommodates 10–22 AWG [0.35 to 6 mm2] wires, making it versatile for automotive, marine, and industrial harness assemblies.

Reliable Electrical Connections

F-crimp design supports consistent crimp quality, reducing resistance and supporting stable signal and power delivery.

High Current Carrying Capability

Supports up to 25 amps (Size 12 contacts), enabling use in both power and low-power circuits.

Enhanced Vibration Resistance

Multi-points of contact and strong crimp tensile strength help maintain connectivity in demanding environments.

Corrosion-Resistant Plating Options

Available with tin, nickel, or gold plating to provide electrical performance and environmental protection.

Harsh Environment Durability

Performs in temperatures from -55°C to 150°C, ideal for commercial vehicles and off-road machinery.

Multiple Contact Sizes

Available in sizes 20, 16, and 12 to match a broad range of current and mechanical requirements.

DEUTSCH stamped & formed common contacts reduce the number of required tools.

Key Features:

DEUTSCH Connector Stamped and Formed Contacts - Reel

| Feature | Description |

|---|---|

| Wire Size Compatibility |

Supports 10–22 AWG (0.35–6.0 mm²) wire sizes |

| Contact Sizes |

Available in Sizes 20, 16 and 12 |

| Current Rating | Up to 25 amps (Size 12 contact at 125°C) |

| Crimp Type | F-crimp design for fast, reliable terminations |

| Contact Retention | Withstands 20–35 lbs depending on contact size |

| Crimp Tensile Strength | Up to 70 lbs for maximum mechanical durability |

| Plating Options | Tin, nickel, and gold for corrosion resistance |

| Operating Temperature Range | -55°C to 150°C for use in harsh environments |

| Durability | Rated for 100+ mating cycles |

| Termination Method | F Crimp termination to wire |

| Product Type | Pin and socket terminals, stamped and formed style |

| Packaging Options | Available in reel formats ranging from 2000 to 4000 parts |

Performance Specifications

Durability: No electrical or mechanical defects after 100 cycles of engagement and disengagement.

Current Rating: Contact current rating @ 125°C

| Contact Size | Max. Current |

|---|---|

| Size 20 | 7.5 amps |

| Size 16 | 13 amps |

| Size 12 | 25 amps |

Contact Retention: Contacts withstand a minimum load of:

- 20 lbs (89 N) for size 20

- 25 lbs (111 N) for size 16

- 30 lbs (133 N) for size 12

Crimp Tensile Strenght

| Contact Size | Tensile Strength |

|---|---|

| Size 20 | 20 lbs |

| Size 16 | 25 lbs |

| Size 12 | 70 lbs |

Contact Millivolt Drop

| Contact Size | Test Current Amps | Millivolt Drop* |

|---|---|---|

| 20 | 7.5 | 100 |

| 16 | 13 | 100 |

| 12 | 25 | 100 |

| * Less drop through wire | ||

| Size | Stamped & Formed Contact Part Numbers |

Carrier Strip Identification |

Wire Size AWG (mm2) | Wire Insulation O.D. Range | Recommended Strip Length Inches (mm) |

Min. Contact Retention | Max. Rated Amps at 125 degree Continous |

|

|---|---|---|---|---|---|---|---|---|

| Pin | Socket | |||||||

| 20 |

1060-20-01** |

1062-20-01** |

20-01 |

16-22 (1.5-.035) |

.075-.125 (1.91-3.18) |

.150-.200 (3.81-5.08) |

20 89 |

7.5 |

| 20 | 1060-20-02** |

1062-20-02** |

20-02 |

16-22 (1.5-.035) |

.051-.085 (1.30-2.16) |

.150-.200 (3.81-5.08) |

20 89 |

7.5 |

| 20 | N/A | 1062-20-03** (Sleeveless) |

20-03 | 16-22 (1.5-.035) |

.075-.125 (1.91-3.18) | .150-.200 (3.81-5.08) | 20 89 |

7.5 |

| 20 | 1060-20-06** | 1062-20-06** | 20-06 | 14-16 (2.5-1.0) |

.075-.125 (1.91-3.18) |

.150-.200 (3.81-5.08) |

20 89 |

7.5 |

| 16 | 1060- 14-01** |

1062- 14-01** |

14-16 | 14-18 (2.0-.75) |

.095-.150 (2.41-3.81) |

.150-.200 (3.81-5.08) |

25 111 |

13 |

| 16 | 1060- 14-10** |

1062- 14-10** |

14-16 | 14-18 (2.0-.75) |

.095-.150 (2.41-3.81) |

.150-.200 (3.81-5.08) |

25 111 |

13 |

| 16 | 1060- 16-01** |

1062- 16-01** |

16-18 | 14-18 (2.0-.75) |

.075-.140 (1.90-3.55) |

.150-.200 (3.81-5.08) |

25 111 |

13 |

| 16 | 1060- 16-06** |

1062- 16-06** |

0.5-1.0 | 16-20 (1.0-.50) |

.055-.100 1.40-2.54) |

.150-.200 (3.81-5.08) |

25 111 |

13 |

| 16 | 1060- 16-09** |

1062- 16-09** |

16-18 | 14-18 (2.0-.75) |

.075-.140 (1.90-3.550 |

.150-.200 (3.81-5.08) |

25 111 |

13 |

| 16 | 1060- 16-12** |

1062- 16-12** |

1.0-2.5 | 12-16 (2.5-1.0) |

.075-.140 (1.90-3.55) |

.175-.225 (4.45-5.72) |

25 111 |

13 |

| 16 | N/A | 1062- (Sleeveless) |

14-16 | 12-16 (2.5-1.0) |

.075-.140 (1.90-3.55) |

.175-.225 (4.45-5.72) |

25 111 |

13 |

| 12 | 1060-12-01** | 1062-12-01** |

12-14 | 12-14 (4.0-2.0) |

.113-.176 (2.87-4.47) |

.225-.275 (5.72-6.99) |

30 134 |

25 |

| 12 | 1060-12-02** | 1062-12-02** | 10-12 | 10■ (6.0-4.0) |

.140-.204 (3.56-5.18) |

.225-.275 (5.72-6.99) |

30 134 |

25 |

** = Plating codes. Consult the factory for custom finish needs.

■ = TXL wire insulation is preferred

Real-world Applications:

DEUTSCH Connector Stamped and Formed Contacts - Reel

Agricultural Equipment Wiring

Used in tractors and implements where wire terminations must withstand outdoor exposure and rugged terrain.

Off-Road and Utility Vehicles

Provides dependable connectivity for construction and mining equipment in the most demanding applications

Commercial Vehicle Electrical Systems

Ideal for use in heavy-duty trucks, construction vehicles, and vocational vehicles that require durable and cost-efficient terminations.

Automotive Wiring Harnesses

Used in cars, trucks, and buses for power distribution, signal routing, and secure interconnects in engine and cabin systems.

Recreational

Provides dependable connectivity for ATVs, utility task vehicles (UTVs) and other recreational equipment such as Suited for boats and marine equipment exposed to the outdoors, moisture, vibration, and temperature fluctuations.

Industrial Machinery and Robotics

Applied in heavy duty stationary equipment, factory automation and control systems for stable connections under repetitive motion and environmental stress.

Learn how to crimp our DEUTSCH contacts. Watch this video for step-by-step instructions on crimping the contacts using hand tools.

DEUTSCH Connector Stamped & Solid Contacts

Also of Interest

DEUTSCH Stamped and Formed Contacts - Reel

Q: What wire sizes are compatible with DEUTSCH stamped and formed contacts?

A: These contacts support wire sizes from 10 to 22 AWG (0.35 to 6.0 mm²), making them suitable for a broad range of signal and power applications.

Q: What current can these contacts handle?

A: Depending on the contact size, they support from 7.5 amps (Size 20) to 25 amps (Size 12) at a continuous operating temperature of 125°C.

Q: What plating options are available for corrosion resistance?

A: DEUTSCH stamped and formed contacts are available with tin, nickel, or gold plating, allowing users to match corrosion protection and conductivity needs to specific application environments.

Q: What if I need bigger contacts? More current and bigger wires?

A: Our range of Solid Contacts offer additional contact sizes for high current / larger wire applications up to 100Amps / 4AWG [25mm2]

READ MORE FAQS ABOUT DEUTSCH CONNECTORS STAMPED & SOLID CONTACTS

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Receptacle Style 180°

-

Primary Locking Feature Integrated in Housing | On the Terminal

-

Sealable No | Yes

Body Features

-

Terminal Seal Type Family Seal or Unsealed

Contact Features

-

Contact Fabrication Stamped & Formed

-

Contact Size Size 12 | Size 16 | Size 20

-

Typical Current Rating (A) 7.5 | 13 | 25

-

Crimp Type F-Crimp

-

Wire Contact Termination Area Plating Material Nickel | Palladium Nickel Gold | Tin

-

Terminal Type Pin | Socket

-

Interface Plating Gold (Au) | Nickel (Ni) | Palladium Nickel Gold (PdNiAu) | Tin (Sn)

-

Mating Pin Diameter (mm) 1 | 1.5 | 1.59 | 2.4

-

Mating Pin Diameter (in) .04 | .06 | .062 | .063 | .094

Termination Features

-

Termination Method to Wire & Cable Crimp

-

Product Terminates To Wire

Dimensions

-

Compatible Insulation Diameter Range (mm) 1.3 – 2.2 | 1.4 – 2.5 | 1.4 – 2.54 | 1.9 – 3.3 | 1.9 – 3.6 | 1.9 – 3.55 | 1.9 – 3.2 | 2.4 – 3.8 | 2.9 – 4.5 | 3.6 – 5.2

-

Compatible Insulation Diameter Range (in) .051 – .085 | .055 – .1 | .074 – .13 | .075 – .14 | .075 – .125 | .095 – .15 | .113 – .176 | .14 – .204

-

Wire Size (AWG) 10 | 14 – 12 | 16 – 12 | 16 – 14 | 18 – 14 | 20 – 16 | 22 – 16

-

Wire Size (mm²) .35 – 1.5 | .5 – 1 | .517 – 1.3 | .75 – 2 | .823 – 2.08 | 1. – 2.5 | 2 – 4 | 4 – 6

-

Wire Size Search (mm²) .35 | .5 | .75 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6

-

Wire Size Search (AWG) 10 | 12 | 14 | 16 | 18 | 20 | 22

Usage Conditions

-

Insulation Option Partially Insulated | Uninsulated

-

Operating Temperature (Max) (°C) 125 | 150

-

Operating Temperature (Max) (°F) 257 | 302

-

Operating Temperature Range (°C) -55 – 150 | -55 – 125

-

Operating Temperature Range (°F) -67 – 302 | -67 – 257

Operation/Application

-

Compatible With Wire Base Material Copper

Packaging Features

-

Packaging Method Package | Reel

-

Packaging Quantity 1 | 2000 | 2500 | 3000 | 3200 | 4000

Other

-

Customer Preferred Contact Yes

-

Terminal Transmits 0 – 24 A (Low Power) | 25 – 40 A (Power)

Flipbook Catalog

- Industrial & Commercial Transportation - Terminals and Connectors (English) TE's Industrial & Commercial Transportation Terminals and Connectors flipbook catalog features AMPSEAL, AMPSEAL 16, Circular DIN, DEUTSCH, HDSCS, LEAVYSEAL, and Superseal 1.0 connectors, contacts, tools, and accessories.

Connector Selector

- Connector Selector (English) The Connector Selector is a reference guide to TE Connectivity's (TE) Industrial & Commercial Transportation electrical connectors.

DEUTSCH, TE Connectivity, and TE connectivity (logo) are trademarks.

Are you sure you want to close chat?

To begin your chat with TE please enter your details

e

e

e

e