Medical Device Laser Marking

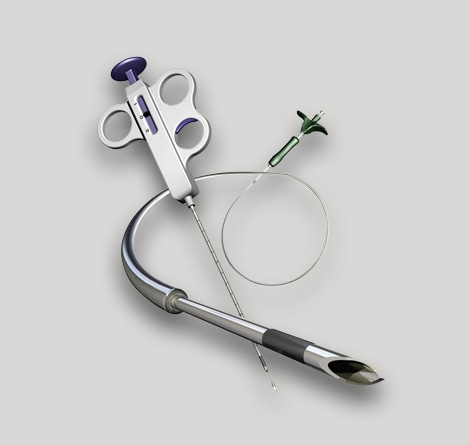

Medical laser marking is the process of applying precise, permanent, high-contrast marks to metal alloys and plastics. Parts and materials can be custom-marked for marker bands, and depth markers to support clinical procedures or manufacturing processes or other information.

TE’s laser marking process is a less invasive alternative to mechanical engraving. Strong enough to withstand harsh environments and conditions, laser-generated engraving keeps material and part surfaces clean and free of physical disturbances. Laser marking is suitable for a wide range of medical instruments including tubing, syringes, orthopedic products, scalpels, clamps, and electronic devices. Laser marking is a more environmentally friendly process, eliminating the need to add coated marker bands or additional materials, reducing the carbon footprint of the product and manufacturing processes.

TE has different forms of laser marking to suit your requirements and to be compliant with other manufacturing processes that the part may see down the line e.g. chemical cleaning. When you need a custom marking solution for medical micro-components, TE is your partner for fast, precise, and clean laser engraving services.

Manufacturing Locations

Technical Resources

Frequently Asked Questions

FAQs

Q: What types of laser processing do you offer?

A: TE Connectivity offers laser cutting, welding, ablation, drilling, and marking, with precision systems optimized for medical device components. We focus on tight-tolerance metal and polymer processing for delivery systems and implants.

Q: What materials can be laser processed (e.g., stainless steel, nitinol, polymers, PEEK)?

A: We laser process a wide range of materials, including 304 and 316L stainless steel, nitinol, MP35N, L605, titanium, and select high-performance polymers like PEEK or PTFE-coated shafts.

Q: Can you help with DFM (design for manufacturability) for laser-processed components?

A: Absolutely. Our engineers will co-develop designs with your team to ensure clean cuts, optimized part geometry, and repeatable processing, reducing downstream scrap and cost.

Q: Can you support both prototyping and high-volume production?

A: Yes — we support early-stage prototyping, pilot builds, and scalable production. We have dedicated lines for development and validated processes for commercial volume manufacturing.

e

e

e

e

e

e

e

e

e

e

e

e