For more details and information on our TE’s Laser Processing capabilities, visit our capabilities page on te.com or download our brochure. You can also connect with our experts to learn more, get samples and design support.

Capabilities & Applications

Q: What types of laser processing do you offer?

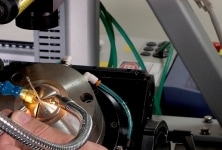

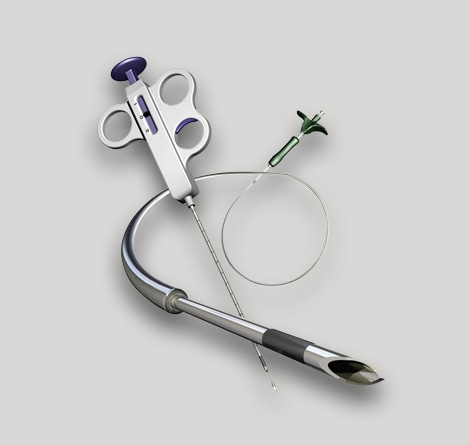

A: TE Connectivity offers laser cutting, welding, ablation, drilling, and marking, with precision systems optimized for medical device components. We focus on tight-tolerance metal and polymer processing for delivery systems and implants.

Q: Can you perform laser cutting on hypotubes, flatsheets, or polymers?

A: Yes — we laser cut metal hypotubes, flat stock, and select engineered polymers (e.g., PEEK, PTFE). Hypotube cutting is a specialty, including steerable shafts and valve delivery systems.

Q: Do you support laser drilling, welding, marking, or ablation?

A: All of the above. We offer laser drilling for ports and fluid pathways, laser welding for component joining, laser marking for traceability, and ablation for coating removal (e.g., on PTFE or hydrophilic surfaces).

Q: Can you create complex geometries like flex cuts or helical patterns?

A: Yes — our systems support spirals, axial slots, bridges, flares, and customized flex patterns with micron-level repeatability, often used in deflectable shafts and stent crimping zones.

Q: Do you support laser micromachining for small, intricate features?

A: We do. Our femtosecond lasers enable high-resolution features, often down to tens of microns, suitable for neurovascular or structural heart devices requiring extreme precision.

Q: What feature sizes and tolerances can you achieve?

A: Typical laser cut feature sizes range from 20–30 μm, and we routinely achieve tolerances of ±10–15 μm, depending on material and geometry.

Materials & Design Considerations

Q: What materials can be laser processed (e.g., stainless steel, nitinol, polymers, PEEK)?

A: We laser process a wide range of materials, including 304 and 316L stainless steel, nitinol, MP35N, L605, titanium, and select high-performance polymers like PEEK or PTFE-coated shafts.

Q: Can you process coated materials (e.g., PTFE-coated hypotubes)?

A: Yes — we can selectively ablate or process PTFE coatings and other polymers.

Q: How does laser cutting affect material properties like grain structure or fatigue life?

A: Our processes are optimized to minimize the heat-affected zone (HAZ) and preserve material integrity. For fatigue-critical components, we offer post-laser annealing, electropolishing, and fatigue testing.

Q: Do you offer heat-affected zone (HAZ) control or post-process annealing?

A: Yes — we control HAZ through beam parameters, shielding gases, and thermal management, and offer post-process annealing where required (e.g., for nitinol or stainless steel).

Q: Can you help with DFM (design for manufacturability) for laser-processed components?

A: Absolutely. Our engineers will co-develop designs with your team to ensure clean cuts, optimized part geometry, and repeatable processing, reducing downstream scrap and cost.

Process Control & Quality

Q: What laser sources do you use (fiber, femtosecond, CO₂, UV)?

A: We use a range of lasers — including fiber, femtosecond, nanosecond, UV, and CO₂ — depending on material and feature requirements. We match the source to your performance and cleanliness needs.

Q: How do you manage burrs, recast layers, and oxidation?

A: We optimise cut parameters to reduce recast and burrs, and we offer post-processing such as electropolishing, chemical etch, bead blasting, and passivation to ensure medical-grade finishes.

Q: Do you offer electropolishing or surface passivation after laser processing?

A: Yes — we routinely electropolish or passivate parts after laser processing to improve corrosion resistance, biocompatibility, and surface finish. This is especially common in hypotube-based shafts and valve delivery components.

Q: Can you perform in-line or post-process inspection (e.g., vision systems, microscopy, metrology)?

A: We use automated vision systems, laser micrometers, digital microscopy, and CMMs for inspecting cut dimensions and features. Custom metrology reports can be provided per customer request.

Q: What is your approach to validating laser processes for Class II/III medical devices?

A: We support full process validation (IQ/OQ/PQ), including GR&R, Cpk analysis, and traceable data collection. Our team partners with yours to support your design history file and regulatory submissions.

Production, Traceability & Compliance

Q: Can you support both prototyping and high-volume production?

A: Yes — we support early-stage prototyping, pilot builds, and scalable production. We have dedicated lines for development and validated processes for commercial volume manufacturing.

Q: Is your laser processing done in an ISO13485-certified facility?

A: Yes — all laser processing for medical devices is performed in ISO 13485-certified environments, with strict process controls, documentation, and traceability.

Q: Do you offer traceability, batch control, and full documentation for regulatory submissions?

A: Yes — we provide a lot of traceability, batch records, and full documentation packages to support EU MDR, FDA, or PMDA regulatory needs.

Q: What are your standard lead times for laser-cut or welded components?

A: Prototypes can typically be turned around in 2–4 weeks, with standard lead times for production around 6–8 weeks, depending on complexity and post-processing needs.

Q: Do you offer assembly-level integration or just component-level processing?

A: Both. We offer component-level services (e.g., laser-cut hypotubes) and integration into subassemblies, including welding, bonding, overmolding, and catheter shaft assembly.

Q: Can you provide PPAP, FAIR, or IQ/OQ/PQ documentation?

A: Yes — we support PPAP (Production Part Approval Process), First Article Inspection Reports (FAIR), and full IQ/OQ/PQ validation in alignment with your quality system requirements.

e

e

e

e

e

e

e

e

e

e

e

e

e

e