Medical Technologies

Manufacture your Micron Resolution Microfluidic Devices Using High Precision Molds and Injection Molding Techniques

Microfluidics is an emerging field that deals with the behavior and manipulation of fluids at the microscale level. Microfluidic devices are widely used in chemical analysis, biomedical research, drug discovery, and in vitro diagnostics. These devices require a high level of dimensional precision and consistency. Injection molding is a common manufacturing technique for mass-producing microfluidic devices. Injection molding can offer several advantages:

- Suitable for high-volume production, making it highly cost-effective

- Helps to enable the production of complex geometries and features with high precision and accuracy

- Precise control over microfluidic channel dimensions and geometries, ensuring consistent feature sizes and tolerances

While it’s easy to design complex features in computer-aided design (CAD), fabricating them is another story. It’s true that micro milling can achieve tolerances down to about ±5 µm and a radius of 0.05 mm, depending on the structure’s aspect ratio. However, based on our experience with industry-leading medical device OEMs, that is simply not precise enough for some complex microfluidic applications with intricate geometries and very tight tolerances. Designing channels and features smaller than these dimensions significantly complicates manufacturing if using conventional micro-milling or molding techniques. So how do you create such small features and tight tolerances while still having a mold that is durable? Enter the nickel shim…

What are Nickel Shims?

Nickel shims (Ni shims) are metal inserts made using electroforming and are applied directly onto master templates made from polymethyl methacrylate (PMMA), cyclic olefin copolymer (COC/COP), or other polymers. They are used to enhance the accuracy and durability of injection molds.

Injection molding is an excellent choice for producing various microstructures used to actuate or control fluid flow, enhance mixing, and execute other functions. Nickel shims bring the potential of injection molding to the next level by fine tuning parameters and help enable the production of precise microfluidic devices with complex geometries.

Ni shims are compatible with mass manufacturing and injection molding methodologies and are an excellent choice for high-volume production.

What About Photolithography?

This is another popular method for producing microfluidic devices. Photolithography allows microfluidic microstructures with resolutions of 1mm on the X and Y axes, and 100nm on the Z axes. While photolithography can be used in the initial prototyping stages, it does not transfer well to mass manufacturing. Once the photolithography mold is created, hot embossing techniques have limited throughput and ultimately become more expensive. Photolithography and hot embossing simply do not lend themselves to high volume manufacturing. In addition, photolithography master molds are not as durable and are easily damaged, requiring more frequent replacement.

Nickel shims are designed to withstand repeated use, so they last longer than photolithography molds. Electroplating can produce highly precise and accurate molds with features as small as a few micrometers. This level of precision helps to enable the production of complex microfluidic devices with high conformance, functionality, and reliability.

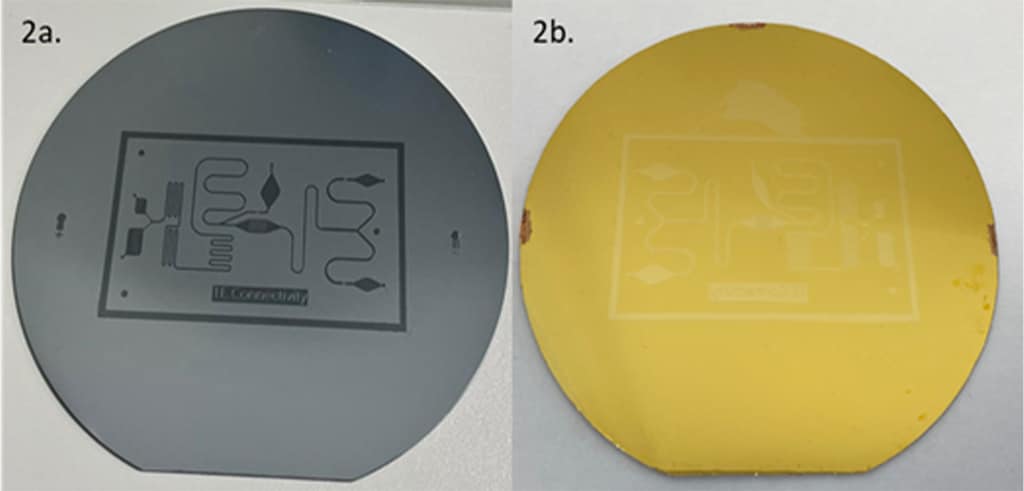

A photolithography master mold (left) and corresponding nickel shim (right ).

Variothermal Injection Molding

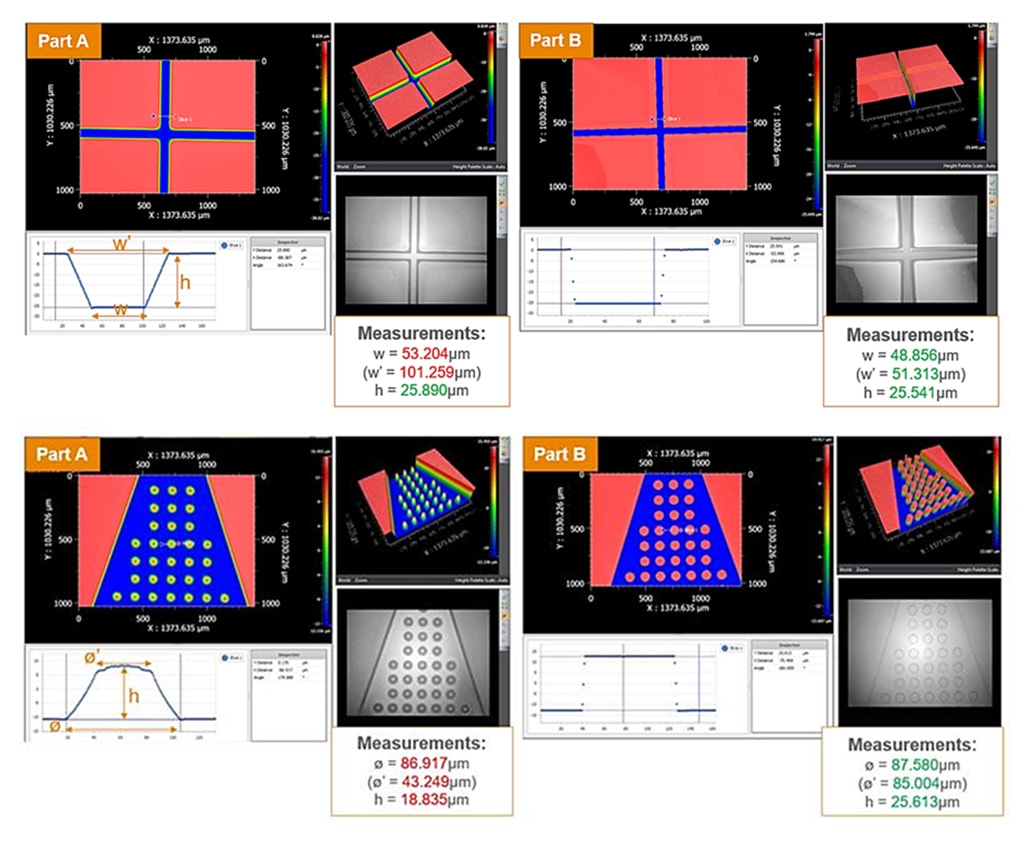

There are many different injection molding process variations. One that works particularly well with nickel shims is variothermal injection molding. This technique involves carefully controlling the temperature of the mold surface. Targeted/localized and process-integrated heating and cooling cycles help to allow significant improvements in quality of the parts. Variothermal injection molding allows surface defects (visible weld lines, flow marks, sink marks, dull halos, color defects) to be avoided and thin wall thicknesses to be achieved. The aspect ratio, a critical parameter for structural design, highlights the challenge of manufacturing and demolding high aspect ratio structures like the pillars in Figure 1 (bottom row). Variothermal injection molding enables the production of these structures with a higher aspect ratio, achieving greater height while enabling structural integrity.

Comparative measurements of microfeatures created using conventional injection versus variothermal injection processes, showing channel intersections (top row) and pillars (bottom row). As indicated by the measurements, variothermal injection molding (shown on the right side of the figure1) produces microchannels with straighter walls and pillars with more uniform dimensions from base to top.

In the example above, conventional injection molding would not allow the proper filling of the microstructures shown. For that reason, variotherm injection molding is the preferred technology when working with molds that have integrated Ni shim inserts. Glass transition temperature (Tg) marks the dramatic change in physical and mechanical properties of a polymer as it transitions from a glassy to rubbery state. It is an important feature of polymer behavior, and the quick heat and cool cycles help to allow the polymer to flow into a cavity that is near or higher than its Tg during the filling stage. This makes the replication of the complex microstructures possible before the polymer starts to solidify when in contact with the mold. It then permits a quick cooling during the same injection cycle for part solidification and posterior ejection.

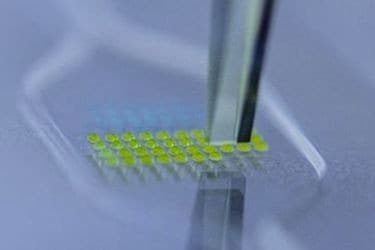

As an example, the part below was made using nickel shims technology and contains structures with depths of 22-78±1µm and tolerances of ±1µm. The flatness is less than 150µm with surface roughness of less than 5nm.

Adding Ni Shims to Photolithography Molds

As mentioned previously, Ni shims make photolithography molds far more durable and precise. This makes the technique a good choice for high volume manufacturing. Moreover, complex Ni shims designs can be achieved with the same resolution as in photolithography. For example, with valving applications rounded channels can be created in one area of the microstructure, and squared channels in other parts of the same device as an optical detection chamber.

Fabrication of single layer same height and multi-layer different heights structures are also possible with Ni shims. Ni shims become very useful in creating finer precision complex structures (i.e., holes and/or pillars), which could be quite challenging with micro molds and micro milling. Generating various degree slopes and radii in the design also become challenging with macro techniques. This design flexibility can be easily achieved by growing a Ni shim on a photolithography master mold.

Are Nickel Shims Right for Your Microfluidic Application?

Conventional molding techniques have some limitations with narrow dimensional tolerances. Adaptation of Ni shims as a manufacturing process allows for microfluidic cartridges with microscale features to be produced in large volumes at similar resolutions achieved by photolithography. Moreover, Ni shims can help you achieve complex patterns by combining different layers and shapes with a tolerance as low as ±1µm. By harnessing the power of Ni shims and variothermal injection mold fabrication techniques, previously unattainable levels of precision and flexibility can be achieved in the field of microfluidics.