Instrument Development

Tap into TE Connectivity's expertise in IVD and Life Science applications with our holistic approach to product development, supporting the microfluidic design with mechatronics and system level interfacing under the same roof, resulting in the shortest path to market for your product.

Effective IVD and Life Science product development depends on the parallel design of hardware and associated consumables to ensure seamless integration at the hardware/consumable interface. Regardless of the complexity of your project, TE brings a wealth of experience in developing robust, reliable, and user-friendly systems and consumables for point-of-care (POC), next-gen sequencing (NGS), liquid biopsy, cell culture, and other applications.

Core Competencies

- Concept Validation

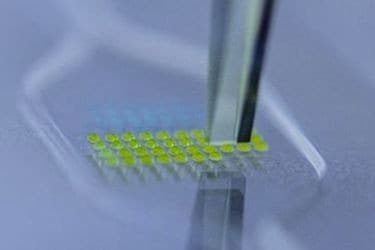

- Microfluidic Development

- Customized Instrumentation

- Laboratory, Point-of-Care and Home-Use Instruments and Devices

- IVD Product Development

- Rapid System Prototyping

- Consumable Loading, Unloading, and Registration

- Lab and Environmental Equipment Design

- Detection and Monitoring Systems

- Rapid Fabrication Systems and Equipment

- Reagent Blister Integration and Management

- Blister Actuation and Mixing Interfaces

- Electronic and Software Interface Control

Reliable Instrument Design

TE simultaneously develops IVD disposable cartridges with associated instruments and hardware systems to ensure a reliable, intuitive system. We work to bring custom onboard hardware processes to life, such as microchannel actuation, blister dispensing, optical monitoring, and more. Our experienced team takes development a step further with clinical research studies to help ensure that your systems are verified and validated for regulatory clearance.TE adheres to ISO 20916 best practices and is ISO 13485 certified, providing a solid platform for IVD development, employing electronic record management, study design, and regulatory strategy development.

Areas of Expertise

IVD Development and Design Considerations

The IVD instrument development process is complex: there are many interconnected design concerns that need to be understood, balanced and managed. TE helps ensure that everyone from designers to regulatory authorities is on the same page. End-user requirements are at the forefront of design, with performance, quality, safety, and regulations close behind. IVD design complexities are effectively reduced with design-for-manufacturing-and-assembly (DFMA) methods, resulting in a high degree of reproducibility, simplicity, and cost-effectiveness. Rigorous testing is carried out to validate device stability, calibration and life expectancy. TE can design packaging, labelling, and IFUs for your IVD device.