Monitor Level Using Differential Pressure

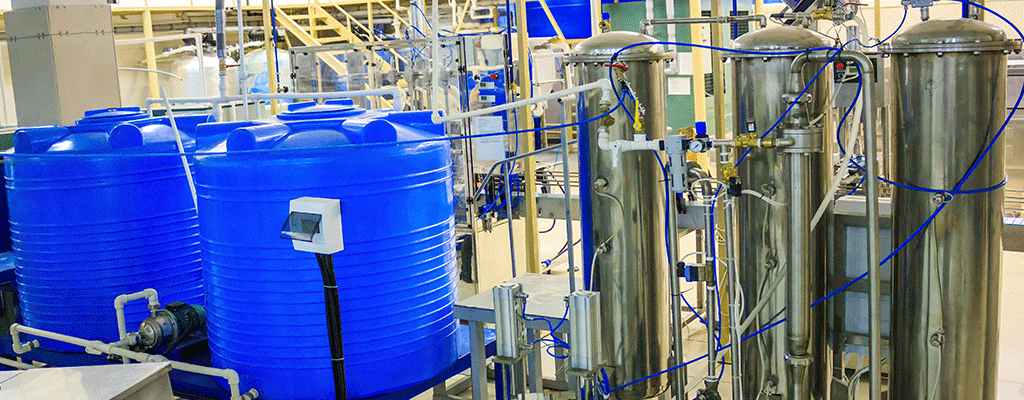

When tanks are sealed from barometric pressure, differential pressure transducers are a reliable, cost-effective way to monitor liquid level.

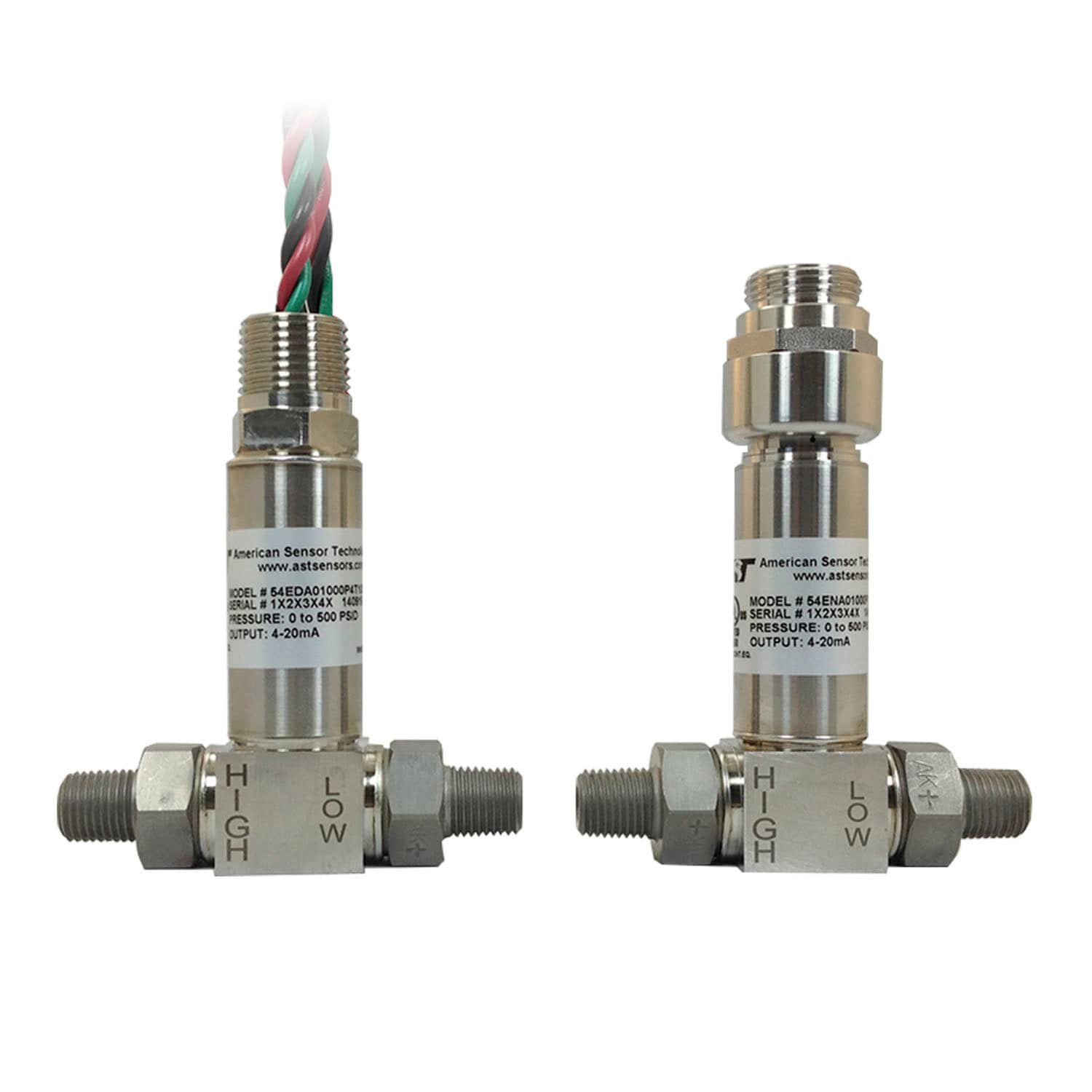

For liquid level measurement in sealed tanks, TE manufactures differential pressure transducers for hazardous and non-hazardous applications. The high / upstream process connection is installed at the bottom of the tank with the low / downstream side installed with 1/4" tubing (minimum) connected to the top of the tank. The larger the diameter of the pipe, the lower the potential of a capillary effect from moisture build up.

Certain applications use pressure or vacuum pressure above the liquid; in these cases the pressurized line can be connected directly to the low side of AST5300. In applications where liquid from the tank or condensation might build up in the low line, a drip leg and drain valve are recommended to maintain accurate level measurement. The drip leg allows incidental condensation to accumulate and re-evaporate without affecting the transducer readings. The drain valve allows for quick maintenance and draining of the line without sensor removal, saving time and money in the long run. By understanding the maximum height of the liquid and its specific gravity, measuring liquid level becomes simple and cost effective.

Technology Advantages

Overall, differential pressure transducers have the advantage over top mounted transmitters in sealed tanks in applications where the fluid is reflective, has foam or is clear. Since the measurement is based on the physical force of the liquid on the diaphragm, there is less chance for error. Using LVDT technology, the AST5300 differential pressure transducer can operate in extremely cold ambient conditions (-50°C) without harm or damage to the device. Designed with extremely high forward proof pressure (1,500 PSI) and burst pressure (5,000 PSI), the AST5300 series can monitor liquid or gas level in storage tanks without fear of rupture.

A wide range of explosion proof and non-incendive approvals are available for Class I, II and III environments. Using the latest technologies in electronics, AST is able to achieve low current consumption for its products. This allows remote telemetry units (RTU's), M2M and SCADA system integrators the ability to apply additional transducers on the same solar circuit or minimize battery maintenance and replacement.