Product Insight

Understanding DIP Switch Configurations

The capability to pre-configure equipment before it is incorporated into a network can help reduce downtime and accelerate changes. These demands are driving more flexibility in the design of DIP switches.

Even before the days of software menus and re-programmable memory, there was a need to customize the behavior of electronic devices. Whether to fine-tune the operation of a machine or set the difficulty of a video game, it was essential to have an easy-to-use method of changing the characteristics of an electronic system. As a solution to this problem, the DIP switch was developed in the early 1970s. More than 40 years later, these DIP switches remain useful and relevant for innovative applications, including technology for the Internet of Things (IoT).

Select DIP Switches

Browse by Type and Element

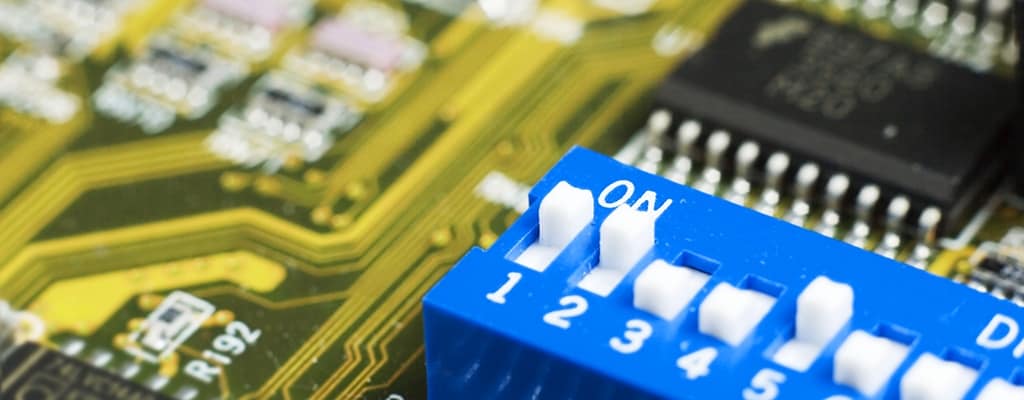

A Dual In-line Package (or DIP) switch has traditionally been manufactured in variety of sizes. These manual electric switches were usually designed with two rows of pins, one on each side. One of the common configurations has been the integrated circuits (ICs) version.

The distance, or pitch, between pins was 0.1” and the distance between rows was 0.3". The standardized package size made it easy for designers to create the printed circuit board (PCB) layout. By using the same interface as the IC, the DIP switch provided a compact switching device that could take advantage of the same mounting techniques.

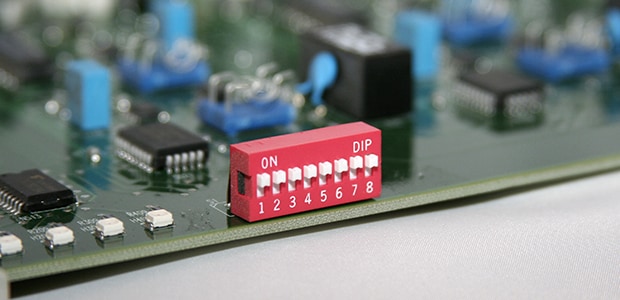

An 8-position DIP switch gives the user up to 256 options (the product of 2 to the eighth power), which is the equivalent of a single byte of information. Therefore, 8 position switches are hugely common, but not always ideal for all applications.

DIP switches use several individual actuators in a variety of styles, including slide, rocker, and piano. These work by offering the user a means to customize the functioning of the PCB with just the movement of a switch. As an electromechanical device, DIP switches offer numerous advantages over software-driven solutions.

Firstly, these provide a visual indication of the position of the switch, making it easier for the user to understand the functioning of the circuit. Secondly, these do not require power for the circuit to be changed. This second feature is particularly interesting.

By using a DIP switch to re-program a device, manufacturers could streamline their production by making one machine that could be customized easily, either in the factory environment or later by the user.

DIP Switches in select applications

As with many other electromechanical solutions to electronics problems, the DIP switch started to fade from use. Innovations in the 1990s included the continued miniaturization of electronics, and the physical size of the DIP switch meant that it found fewer applications in the consumer products of the day. Non-volatile memory became cheaper and more compact, allowing equipment re-programming to be software driven.

The DIP switch has never disappeared entirely, however. Its usefulness makes it relevant for use in many applications, including high-performance technology. For example, the Internet of Things (IoT) has given rise to new advanced applications in the home and factory, with consumer devices and industrial machinery capable of delivering unprecedented connectivity, coupled with flexibility and rapid installation.

DIP switches are designed for this sort of configuration as new elements of a connected home or smart factory are installed. The capability to pre-configure equipment before it is incorporated into a network means that downtime is kept to a minimum and changes can be made rapidly. This has led to demands for a new type of flexibility in the design of DIP switches.

By using a DIP switch to re-program a device, manufacturers could streamline their production by making one machine that could be customized easily, either in the factory environment or later by the user.

Today, space on the PCB is at a premium, and engineers need solutions not limited by standardized form factors. To enable this, we developed the single-position, end-stackable DIP switch. This innovation allows engineers to create to customize a DIP switch, making the best use of the space available and avoiding the inconvenience of having to choose components with features they do not need. The result is a product that can help you meet your requirements. Learn about the solutions we offer for your applications. Start shopping our portfolio of DIP switches.

e

e

e

e

e

e

e

e

e

e