Improve the life/load performance of relay contacts

Referenced Application Notes

Introduction

Throughout this Application Note, references to “relay(s)” may generally be assumed to apply to “contactor(s)” as well. Similarly, little is specifically mentioned regarding application of “telecommunications type relays”. Generally, the need for proper coil drive applies equally to contactors and telecommunications relays except that increased internal and coil temperature rise due to contact load is seldom an issue in telecommunications applications.

Proper coil drive is critically important for correct relay operation and good load/life performance. In order for a relay (or contactor) to function properly, it is necessary to ensure that the coil is properly driven so that the contacts close correctly and remain closed, and the armature seats fully and remains seated, over all conditions that might be encountered in the application.

Regardless of whether the coil type is DC or AC, all relay contact ratings for AC load-life are assumed to be randomly switched with respect to the AC power line cycle, distributed evenly around the entire cycle over time, and with equal probability of switching in both positive and negative cycles. One must take care that the control hardware and software does not inadvertently cause line-syncing of contact opening and/or closure - which will result in uneven or accelerated contact wear and early failure.

Relays are electro-magnets, and the strength of the magnetic field operating them is a function of ampere-turns (AT) - (i.e. the number of turns of wire multiplied by the current flowing through that wire). Since the number of “turns” does not change once wound, the only application variable is the coil current.

DC coil current is solely determined by the applied voltage and the resistance of the coil. If voltage decreases or resistance increases, then coil current decreases - resulting in lower AT and thus reduced magnetic force in the coil.

AC coil current is similarly affected by applied voltage and coil impedance - but the impedance(Z) is defined as Z=sqrt(R2 + XL 2 ) so changes to coil resistance alone have a somewhat less direct effect on AC coils than on DC coils.

The applied coil voltage will also vary as the power supply varies over time. The control designer must define the input voltage range over which the control is guaranteed to operate (typically +10%/-20% of nominal) and then compensate in the control design to assure proper operation over that voltage range.

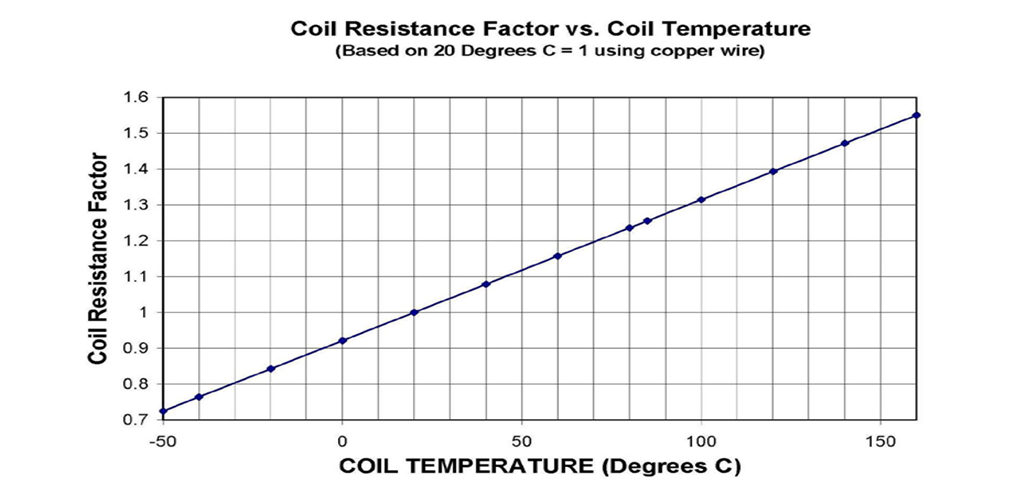

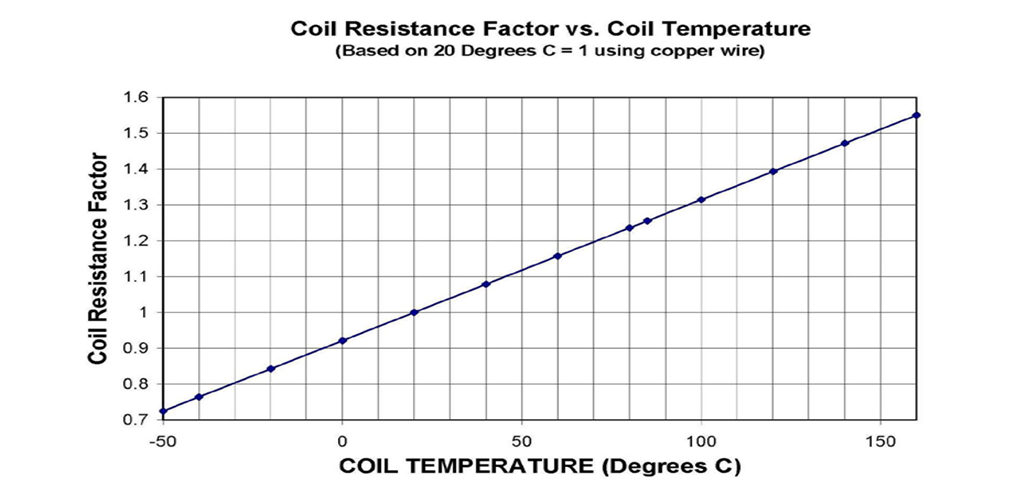

Not only will there be variations in the applied voltage, but the relay coil resistance has similar variations. First, coil resistance will have a manufacturing tolerance (typically +/-5% or +/-10% at room temperature). Secondly, the resistance of the coil wire also has a positive temperature coefficient so the coil resistance will increase as the wire temperature increases or decrease as the wire temperature decreases. This is shown graphically following and also in more detail in Application Note “Coil Voltage and Temperature Compensation”.

Effect of Temperature on Coil Performance

Coil resistance versus temperature (Graphically):

Definitions of Terminology

- Coil resistance - The DC resistance of the relay coil is usually specified at “room” temperature (typically 23°C). Also see Application Note “Coil Voltage and Temperature Compensation”.

- Operate (Pull-in) Voltage - The voltage at or below which the relay armature must be seated against the coil core by assuming its fully operated position.

- Release (Drop-out) Voltage - The specified voltage at or above which the relay armature must restore to its unoperated position.

- Hold Voltage - The voltage at or above which the armature is required not to move perceptibly from its fully operated position after having been energized electrically. (Note that this is normally not specified on datasheets or controlled in manufacturing) - More on this later in the section on Coil Power Reduction and also in Application Note “DC Relay Coil Power Reduction Options”.

Correct DC Coil Voltage over Worst Case Conditions

(Note: Beyond this point, DC coil relays are always assumed to be powered by well filtered DC - not unfiltered half-wave or fullwave unless specifically noted. Furthermore, datasheet information is assumed to be at room temperature (typically. 23°C unless otherwise noted).

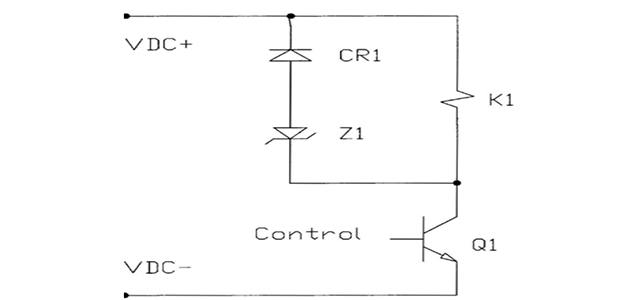

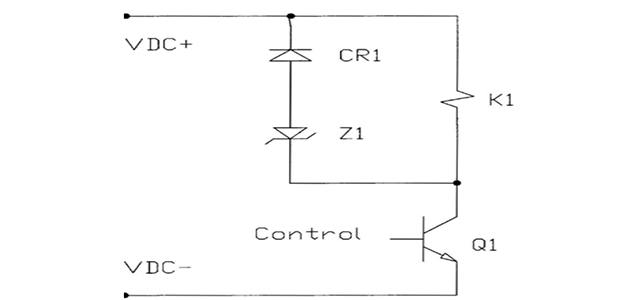

Typical DC Relay Coil Drive Circuit

Diode CR1 serves to snub the reverse “kickback” voltage from the relay coil K1 to protect the driver Q1 when turning OFF but it also has the effect of slowing contact dropout which may degrade load-life. Zener Z1 is optional, but when used it reduces the dropout slowing effect of CR1. The Z1 zener voltage is selected at no more than 80% of the PIV of transistor Q1.

If unfiltered half-wave or full-wave DC coil power is to be used, diode CR1 must be provided across the coil (and Z1 must not be used) so that energy will re-circulate to the coil and allow it to ride-through the low voltage portions of the power waveform without unseating the armature, buzzing, etc. Consult TE Relay Products Engineering for advice. Conditions vary significantly by relay/contactor type and the circuit design. Some relays tolerate this well and others not at all.

The worst case operating conditions for a relay are at minimum supply voltage and maximum coil resistance at the highest ambient temperature concurrent with the highest contact current loading. Inductance divided by resistance (L/R) defines the charge and discharge rate of the current in relay coils and thus affects their operate time (and release time if diode or diode-zener snubbed). L/R also varies by relay type, coil voltage and ambient temperature. Similarly, this results in variations in operate and release timing as well as in tolerance to half-wave and full-wave operation - all of which must be considered in each application.

It is important to subtract out and correct for voltage drops in the coil circuit due to series diodes, transistors (especially Darlington), etc. so that the minimum voltage actually applied to the coil remains as required.

Self-heating via I2 R losses in the relay due to current through the coil wire and load current through the contact arms and terminals results in additional coil and internal part heating {in addition to any increases in ambient temperature alone). All need to be considered when computing actual coil temperature.

The designer should always correct the input voltage to adjust for the increased coil resistance, circuit losses and decreased AT so that, under worst case conditions, there is still enough AT to reliably operate the relay and to fully seat the armature so that there is full contact force applied. If the contact is closed but the armature is not fully seated, the contact force will be low, thus the contact(s) may be subject to overheating and prone to tack-welding upon application of high currents.

- Note: AC coils are corrected similarly while remembering that the resistance change affects the AC coil impedance (and therefore the coil current) by the formula Z=sqrt(R2 + XL 2 ) rather than linearly as on DC coils.

See Application Note “Coil Voltage and Temperature Compensation” for a detailed discussion of these issues.

Additional Coil Drive Design Considerations

- The maximum coil temperature (calculated per Application Note “Coil Voltage and Temperature Compensation”) at nominal coil voltage, maximum load and maximum ambient temperature should not exceed the maximum temperature allowed by UL or CSA for the “Insulation Temperature Class” (A, B, F or H - (105°C, 130°C, 155°C and 180°C respectively)) of the relay selected.

- If the relays will be heavily loaded and tightly packed in the final assembly or if they are near other heat producing components, a higher coil temperature rise can be expected and must be similarly defined and compensated.

- All sources of heating discussed previously must be considered so that coils are properly driven without temperatures exceeding the Insulation System limits.

- Since relays are electromagnets, they are susceptible to external magnetic fields from nearby transformers, other relays or contactors, high current conductors, etc.; all of which can influence the Operate and Release characteristics of the relay. Similarly, relays and contactors may influence the performance of other magnetically sensitive components near them.

- The ultimate test is in the final assembly when the relay is exposed to maximum loading, maximum ambient temperature and minimum power supply voltage. Under these conditions, the coil temperature rise (and thus resistance change) should be re-evaluated to make sure that there is still a sufficient safety factor to reliably drive the relay at low supply voltage without overheating at maximum supply voltage, load current and ambient temperature.

- Characteristics unique to AC coils will be discussed in more detail later in this Note.

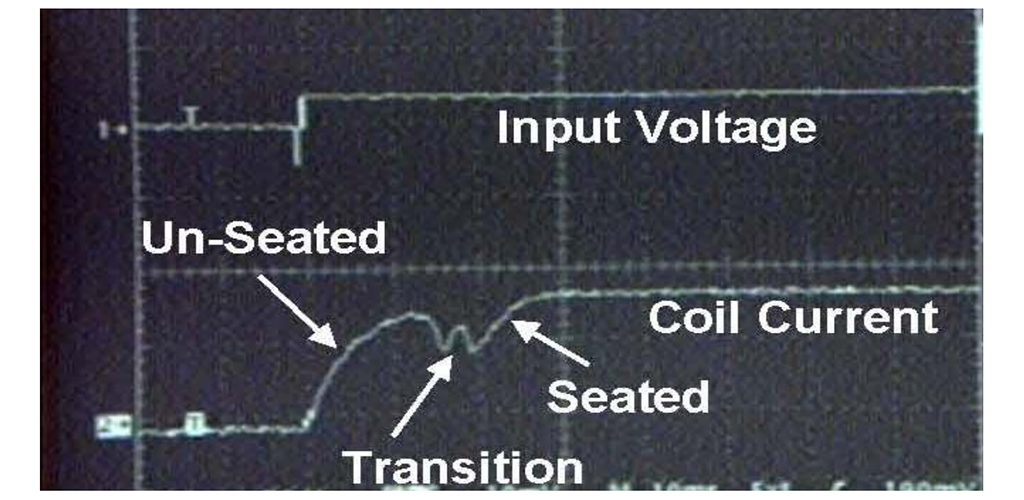

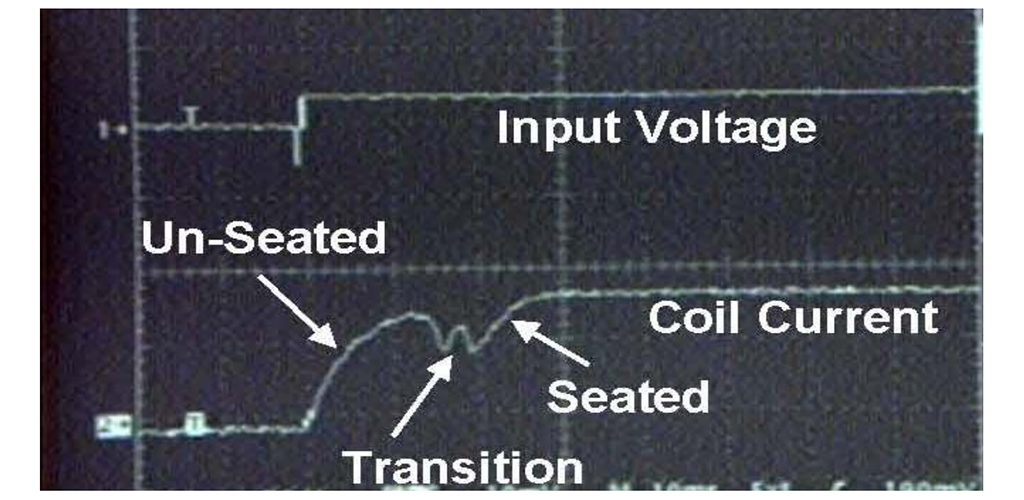

- For DC coils the coil current waveform during initial operation must look like Figure “A” and not like Figure “B”.

Figure A. Good Transition

Figure B. Bad Transition

If the coil current transition looks like Figure “B” (which indicates that the armature “stalled” momentarily and did not seat firmly) something is wrong with the drive circuit that needs to be corrected.

If the coil current transition looks like Figure “B” (which indicates that the armature “stalled” momentarily and did not seat firmly) something is wrong with the drive circuit that needs to be corrected.

If the coil current transition looks like Figure “B” (which indicates that the armature “stalled” momentarily and did not seat firmly) something is wrong with the drive circuit that needs to be corrected.

DC Coil Latching Relays with Remanent Magnet Systems

DC latching relays using remanent magnet systems are special DC coil relays that only need to be powered for a short time to “SET” them and then again to “RESET” them. These coils are normally not intended to be continuously powered in either Set or Reset mode.

- All previous comments about proper coil drive of DC relays and correction for increased ambient temperature, etc. apply except for coil heating due to applied coil voltage.

- These relays have much more restricted requirements for both applied voltage range and “on time” than do monostable relays.

The SET voltage should normally not exceed 120% of the nominal rated voltage. RESET voltage, on the other hand, should never exceed 120% of nominal voltage and is best kept to 110% maximum or the risk of “upsetting” (RESETTING, then SETTING again) the magnet system increases. Where wide ambient temperature ranges are needed, please consult TE Relay Products Engineering for guidance.

Minimum SET and RESET time intervals are specified on the relay datasheet. These minimum times are much longer than the actual time needed to transfer the contact to its opposite state. The extra time is necessary so that the magnet system is appropriately “charged” at each step.

- Similarly, “charge pump” or other pulsed coil drive schemes which utilize discharging capacitors as a power source, are not recommended because it is very difficult to maintain sufficient current over the proper time interval to SET or RESET the relay without exceeding the maximum AT the magnet system will tolerate - especially on RESET.

Characteristics of AC Coil Relays and Contactors

Relays and contactors using AC coils have some important differences from DC types. Because of the sinusoidal nature of AC power:

- Some AC relays tend to “hum”audibly even though they work correctly. This may vary from relay to relay, operation to operation and over life. “Hum” is an audible sound that does not appreciably move the internal parts of the relay or the contacts. “Buzz” or “chatter” on the other hand, is louder and physically moves internal parts and so must never be allowed to occur or performance will be greatly degraded.

- AC relays cannot be intentionally synchronized to the AC sine-wave because parts of the AC sine-wave do not contain enough energy to operate the relay mechanism - so there are points where relay operate and release timing just cannot work correctly.

- This phenomena also results in more variation in operate and release timing than in DC relays and often in increased contact or armature bounce or chatter. All this is dependent upon exactly where in the sine-wave the coil power is connected or removed and can even cause excessive contact bounce or chatter when initially operated.

- As a result, AC relays typically carry a lower rating than DC relays of the same family. This is because 1) the sinewave has low energy spots (as explained previously) and so AC relay contacts do not randomly break over the entire cycle in both polarities and 2) this can result in an excessively high incidence of making and/or breaking in high energy portions of the sine-wave. All these features tend to reduce contact ratings or contact life on AC-coil devices.

- AC coil relays typically run hotter than DC types so the maximum ambient temperature allowed is often less than on DC models.

- Similarly, AC coil relays driven by triacs or back-to-back SCRs will tend to have a shorter life. Such devices can normally be gated ON, and will come on, at any point in the cycle. They may also be gated OFF anywhere - but they will not actually turn OFF until the current through them reaches zero. This results in contacts “breaking” the load at a nearly fixed point in the power cycle. If the “release time” of the relay makes that happen near zero current, performance is better than average, but if it happens near peak current then performance is much worse. Datasheet and safety-agency load-life ratings are based on totally random cycling with respect to the AC sine-wave (not this synchronous condition) unless otherwise specified in the reports.

Coil power Reduction Schemes (DC Coil Relays Only)

It is sometimes desirable to reduce total control power consumption and reduce heating. One way to do this is to use relays with latching mechanisms, however they are relatively expensive and may leave the relay in an undetermined state in the event of a power failure. An alternative is to reduce the coil power consumption on standard DC coil relays using one of the following techniques.

- PWM (Pulse Width Modulation) - With this scheme, the DC coil relay or contactor is initially operated at nominal coil voltage, or slightly above, for a short interval to operate and stabilize the relay mechanism. The relay coil is then driven by a rectangular wave pulse train of some specified amplitude, duty-cycle and frequency to hold the relay in the operated condition with less power applied.

- Step-Down DC Coil Drive - Like PWM, this technique initially operates the relay at nominal rated DC coil voltage for a short interval to operate and stabilize the mechanism. Then the DC voltage is reduced to a lower level to hold the relay in the operated condition with less power applied.

- Caution - Use of “charge-pump” and similar other schemes can accomplish the same purpose, but they use charging/discharging capacitors for power. The resulting non-rectangular wave-shape makes it very difficult to ensure that stable, proper coil power is applied to the relay coil for the proper time interval to properly operate the relay or to hold it properly engaged while reducing coil power. Though commonly used, such schemes are not recommended due to the difficulty in ensuring proper coil drive.

Similarly, one must always remember that reduction of coil power reduces the holding power of the relay’s coil and thus reduces shock and vibration tolerance in the application.

TE Relay Products Engineering should be consulted for relay family specific information for all of these techniques. Not all relays perform the same.

Contact Load/Life Performance Enhancement

- Zero-Cross Syncing - There are various techniques that may allow DC coil relays to perform better than their published load/life rating (for AC loads when randomly switched). This usually involves some sort of zero-cross syncing of the contact to the load voltage waveform on “make” and to the load current waveform on “break”. Properly done, exceptional improvements in switching life can be achieved when using resistive loads, reactive loads and especially high-inrush capacitive and lamp loads.

There are also several contact performance issues related to potentially increased contact resistance when switching very accurately near to zero-crossing on both “make” and “break” since there is no self-cleaning by breaking arcs to reduce normally occurring contact oxidation and contamination over the life of the relay.

This is an inherently complex process and it is discussed separately and in more detail in Application Note “Contact Load/Life Performance Enhancement”.

TE Relay Products Engineering should be consulted for relay family specific information for this technique. Not all relays perform in the same ways.

Improve the life/load performance of relay contacts

Referenced Application Notes

Introduction

Throughout this Application Note, references to “relay(s)” may generally be assumed to apply to “contactor(s)” as well. Similarly, little is specifically mentioned regarding application of “telecommunications type relays”. Generally, the need for proper coil drive applies equally to contactors and telecommunications relays except that increased internal and coil temperature rise due to contact load is seldom an issue in telecommunications applications.

Proper coil drive is critically important for correct relay operation and good load/life performance. In order for a relay (or contactor) to function properly, it is necessary to ensure that the coil is properly driven so that the contacts close correctly and remain closed, and the armature seats fully and remains seated, over all conditions that might be encountered in the application.

Regardless of whether the coil type is DC or AC, all relay contact ratings for AC load-life are assumed to be randomly switched with respect to the AC power line cycle, distributed evenly around the entire cycle over time, and with equal probability of switching in both positive and negative cycles. One must take care that the control hardware and software does not inadvertently cause line-syncing of contact opening and/or closure - which will result in uneven or accelerated contact wear and early failure.

Relays are electro-magnets, and the strength of the magnetic field operating them is a function of ampere-turns (AT) - (i.e. the number of turns of wire multiplied by the current flowing through that wire). Since the number of “turns” does not change once wound, the only application variable is the coil current.

DC coil current is solely determined by the applied voltage and the resistance of the coil. If voltage decreases or resistance increases, then coil current decreases - resulting in lower AT and thus reduced magnetic force in the coil.

AC coil current is similarly affected by applied voltage and coil impedance - but the impedance(Z) is defined as Z=sqrt(R2 + XL 2 ) so changes to coil resistance alone have a somewhat less direct effect on AC coils than on DC coils.

The applied coil voltage will also vary as the power supply varies over time. The control designer must define the input voltage range over which the control is guaranteed to operate (typically +10%/-20% of nominal) and then compensate in the control design to assure proper operation over that voltage range.

Not only will there be variations in the applied voltage, but the relay coil resistance has similar variations. First, coil resistance will have a manufacturing tolerance (typically +/-5% or +/-10% at room temperature). Secondly, the resistance of the coil wire also has a positive temperature coefficient so the coil resistance will increase as the wire temperature increases or decrease as the wire temperature decreases. This is shown graphically following and also in more detail in Application Note “Coil Voltage and Temperature Compensation”.

Effect of Temperature on Coil Performance

Coil resistance versus temperature (Graphically):

Definitions of Terminology

- Coil resistance - The DC resistance of the relay coil is usually specified at “room” temperature (typically 23°C). Also see Application Note “Coil Voltage and Temperature Compensation”.

- Operate (Pull-in) Voltage - The voltage at or below which the relay armature must be seated against the coil core by assuming its fully operated position.

- Release (Drop-out) Voltage - The specified voltage at or above which the relay armature must restore to its unoperated position.

- Hold Voltage - The voltage at or above which the armature is required not to move perceptibly from its fully operated position after having been energized electrically. (Note that this is normally not specified on datasheets or controlled in manufacturing) - More on this later in the section on Coil Power Reduction and also in Application Note “DC Relay Coil Power Reduction Options”.

Correct DC Coil Voltage over Worst Case Conditions

(Note: Beyond this point, DC coil relays are always assumed to be powered by well filtered DC - not unfiltered half-wave or fullwave unless specifically noted. Furthermore, datasheet information is assumed to be at room temperature (typically. 23°C unless otherwise noted).

Typical DC Relay Coil Drive Circuit

Diode CR1 serves to snub the reverse “kickback” voltage from the relay coil K1 to protect the driver Q1 when turning OFF but it also has the effect of slowing contact dropout which may degrade load-life. Zener Z1 is optional, but when used it reduces the dropout slowing effect of CR1. The Z1 zener voltage is selected at no more than 80% of the PIV of transistor Q1.

If unfiltered half-wave or full-wave DC coil power is to be used, diode CR1 must be provided across the coil (and Z1 must not be used) so that energy will re-circulate to the coil and allow it to ride-through the low voltage portions of the power waveform without unseating the armature, buzzing, etc. Consult TE Relay Products Engineering for advice. Conditions vary significantly by relay/contactor type and the circuit design. Some relays tolerate this well and others not at all.

The worst case operating conditions for a relay are at minimum supply voltage and maximum coil resistance at the highest ambient temperature concurrent with the highest contact current loading. Inductance divided by resistance (L/R) defines the charge and discharge rate of the current in relay coils and thus affects their operate time (and release time if diode or diode-zener snubbed). L/R also varies by relay type, coil voltage and ambient temperature. Similarly, this results in variations in operate and release timing as well as in tolerance to half-wave and full-wave operation - all of which must be considered in each application.

It is important to subtract out and correct for voltage drops in the coil circuit due to series diodes, transistors (especially Darlington), etc. so that the minimum voltage actually applied to the coil remains as required.

Self-heating via I2 R losses in the relay due to current through the coil wire and load current through the contact arms and terminals results in additional coil and internal part heating {in addition to any increases in ambient temperature alone). All need to be considered when computing actual coil temperature.

The designer should always correct the input voltage to adjust for the increased coil resistance, circuit losses and decreased AT so that, under worst case conditions, there is still enough AT to reliably operate the relay and to fully seat the armature so that there is full contact force applied. If the contact is closed but the armature is not fully seated, the contact force will be low, thus the contact(s) may be subject to overheating and prone to tack-welding upon application of high currents.

- Note: AC coils are corrected similarly while remembering that the resistance change affects the AC coil impedance (and therefore the coil current) by the formula Z=sqrt(R2 + XL 2 ) rather than linearly as on DC coils.

See Application Note “Coil Voltage and Temperature Compensation” for a detailed discussion of these issues.

Additional Coil Drive Design Considerations

- The maximum coil temperature (calculated per Application Note “Coil Voltage and Temperature Compensation”) at nominal coil voltage, maximum load and maximum ambient temperature should not exceed the maximum temperature allowed by UL or CSA for the “Insulation Temperature Class” (A, B, F or H - (105°C, 130°C, 155°C and 180°C respectively)) of the relay selected.

- If the relays will be heavily loaded and tightly packed in the final assembly or if they are near other heat producing components, a higher coil temperature rise can be expected and must be similarly defined and compensated.

- All sources of heating discussed previously must be considered so that coils are properly driven without temperatures exceeding the Insulation System limits.

- Since relays are electromagnets, they are susceptible to external magnetic fields from nearby transformers, other relays or contactors, high current conductors, etc.; all of which can influence the Operate and Release characteristics of the relay. Similarly, relays and contactors may influence the performance of other magnetically sensitive components near them.

- The ultimate test is in the final assembly when the relay is exposed to maximum loading, maximum ambient temperature and minimum power supply voltage. Under these conditions, the coil temperature rise (and thus resistance change) should be re-evaluated to make sure that there is still a sufficient safety factor to reliably drive the relay at low supply voltage without overheating at maximum supply voltage, load current and ambient temperature.

- Characteristics unique to AC coils will be discussed in more detail later in this Note.

- For DC coils the coil current waveform during initial operation must look like Figure “A” and not like Figure “B”.

Figure A. Good Transition

Figure B. Bad Transition

If the coil current transition looks like Figure “B” (which indicates that the armature “stalled” momentarily and did not seat firmly) something is wrong with the drive circuit that needs to be corrected.

If the coil current transition looks like Figure “B” (which indicates that the armature “stalled” momentarily and did not seat firmly) something is wrong with the drive circuit that needs to be corrected.

If the coil current transition looks like Figure “B” (which indicates that the armature “stalled” momentarily and did not seat firmly) something is wrong with the drive circuit that needs to be corrected.

DC Coil Latching Relays with Remanent Magnet Systems

DC latching relays using remanent magnet systems are special DC coil relays that only need to be powered for a short time to “SET” them and then again to “RESET” them. These coils are normally not intended to be continuously powered in either Set or Reset mode.

- All previous comments about proper coil drive of DC relays and correction for increased ambient temperature, etc. apply except for coil heating due to applied coil voltage.

- These relays have much more restricted requirements for both applied voltage range and “on time” than do monostable relays.

The SET voltage should normally not exceed 120% of the nominal rated voltage. RESET voltage, on the other hand, should never exceed 120% of nominal voltage and is best kept to 110% maximum or the risk of “upsetting” (RESETTING, then SETTING again) the magnet system increases. Where wide ambient temperature ranges are needed, please consult TE Relay Products Engineering for guidance.

Minimum SET and RESET time intervals are specified on the relay datasheet. These minimum times are much longer than the actual time needed to transfer the contact to its opposite state. The extra time is necessary so that the magnet system is appropriately “charged” at each step.

- Similarly, “charge pump” or other pulsed coil drive schemes which utilize discharging capacitors as a power source, are not recommended because it is very difficult to maintain sufficient current over the proper time interval to SET or RESET the relay without exceeding the maximum AT the magnet system will tolerate - especially on RESET.

Characteristics of AC Coil Relays and Contactors

Relays and contactors using AC coils have some important differences from DC types. Because of the sinusoidal nature of AC power:

- Some AC relays tend to “hum”audibly even though they work correctly. This may vary from relay to relay, operation to operation and over life. “Hum” is an audible sound that does not appreciably move the internal parts of the relay or the contacts. “Buzz” or “chatter” on the other hand, is louder and physically moves internal parts and so must never be allowed to occur or performance will be greatly degraded.

- AC relays cannot be intentionally synchronized to the AC sine-wave because parts of the AC sine-wave do not contain enough energy to operate the relay mechanism - so there are points where relay operate and release timing just cannot work correctly.

- This phenomena also results in more variation in operate and release timing than in DC relays and often in increased contact or armature bounce or chatter. All this is dependent upon exactly where in the sine-wave the coil power is connected or removed and can even cause excessive contact bounce or chatter when initially operated.

- As a result, AC relays typically carry a lower rating than DC relays of the same family. This is because 1) the sinewave has low energy spots (as explained previously) and so AC relay contacts do not randomly break over the entire cycle in both polarities and 2) this can result in an excessively high incidence of making and/or breaking in high energy portions of the sine-wave. All these features tend to reduce contact ratings or contact life on AC-coil devices.

- AC coil relays typically run hotter than DC types so the maximum ambient temperature allowed is often less than on DC models.

- Similarly, AC coil relays driven by triacs or back-to-back SCRs will tend to have a shorter life. Such devices can normally be gated ON, and will come on, at any point in the cycle. They may also be gated OFF anywhere - but they will not actually turn OFF until the current through them reaches zero. This results in contacts “breaking” the load at a nearly fixed point in the power cycle. If the “release time” of the relay makes that happen near zero current, performance is better than average, but if it happens near peak current then performance is much worse. Datasheet and safety-agency load-life ratings are based on totally random cycling with respect to the AC sine-wave (not this synchronous condition) unless otherwise specified in the reports.

Coil power Reduction Schemes (DC Coil Relays Only)

It is sometimes desirable to reduce total control power consumption and reduce heating. One way to do this is to use relays with latching mechanisms, however they are relatively expensive and may leave the relay in an undetermined state in the event of a power failure. An alternative is to reduce the coil power consumption on standard DC coil relays using one of the following techniques.

- PWM (Pulse Width Modulation) - With this scheme, the DC coil relay or contactor is initially operated at nominal coil voltage, or slightly above, for a short interval to operate and stabilize the relay mechanism. The relay coil is then driven by a rectangular wave pulse train of some specified amplitude, duty-cycle and frequency to hold the relay in the operated condition with less power applied.

- Step-Down DC Coil Drive - Like PWM, this technique initially operates the relay at nominal rated DC coil voltage for a short interval to operate and stabilize the mechanism. Then the DC voltage is reduced to a lower level to hold the relay in the operated condition with less power applied.

- Caution - Use of “charge-pump” and similar other schemes can accomplish the same purpose, but they use charging/discharging capacitors for power. The resulting non-rectangular wave-shape makes it very difficult to ensure that stable, proper coil power is applied to the relay coil for the proper time interval to properly operate the relay or to hold it properly engaged while reducing coil power. Though commonly used, such schemes are not recommended due to the difficulty in ensuring proper coil drive.

Similarly, one must always remember that reduction of coil power reduces the holding power of the relay’s coil and thus reduces shock and vibration tolerance in the application.

TE Relay Products Engineering should be consulted for relay family specific information for all of these techniques. Not all relays perform the same.

Contact Load/Life Performance Enhancement

- Zero-Cross Syncing - There are various techniques that may allow DC coil relays to perform better than their published load/life rating (for AC loads when randomly switched). This usually involves some sort of zero-cross syncing of the contact to the load voltage waveform on “make” and to the load current waveform on “break”. Properly done, exceptional improvements in switching life can be achieved when using resistive loads, reactive loads and especially high-inrush capacitive and lamp loads.

There are also several contact performance issues related to potentially increased contact resistance when switching very accurately near to zero-crossing on both “make” and “break” since there is no self-cleaning by breaking arcs to reduce normally occurring contact oxidation and contamination over the life of the relay.

This is an inherently complex process and it is discussed separately and in more detail in Application Note “Contact Load/Life Performance Enhancement”.

TE Relay Products Engineering should be consulted for relay family specific information for this technique. Not all relays perform in the same ways.