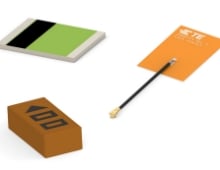

Our broad portfolio of antennas includes products designed for Wi-Fi, cellular, GNSS, RFID, IoT, DAS, and more. Our antennas are engineered for use in cars, heavy-transport vehicles including rail, and a wide variety of personal electronics, including mobile device and wearable technology. Our antennas offer high-quality transmission for a wide variety of frequencies including, but not limited to Bluetooth, WLAN, and Zigbee. We manufacture our antennas in facilities worldwide, which include testing capabilities in near and far field patterns, scattering parameters, SAR, vibration, humidity, temperature shock, salt fog, throughput, and acoustic. We also manufacture antenna assemblies.

Browse our Extensive Portfolio

TE Connectivity has one of the broadest antenna offerings available with antennas ranging from millimeters to meters for many frequencies. The documents below will give you an insight into our portfolio and just some of the options we have with industry partner products.

Insight on Antenna Design and Placement

Other References