-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples (with Business email address)

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

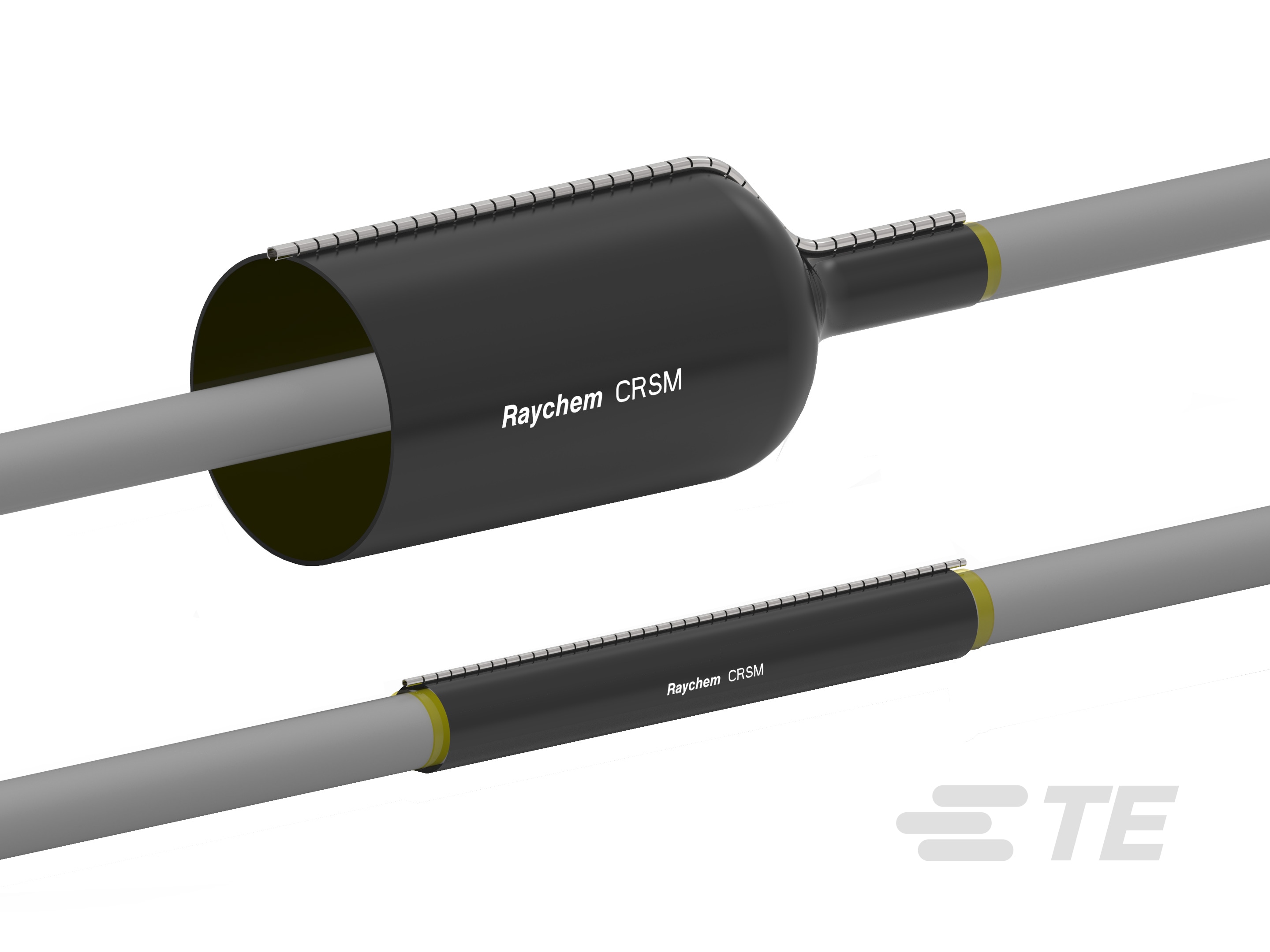

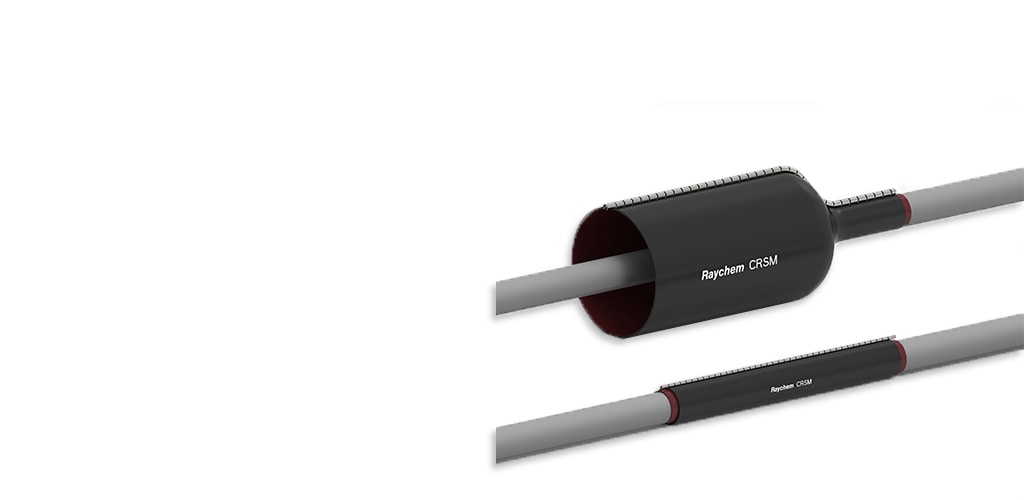

Wraparound Sleeve for Cable Repair

- RAYCHEM

- RAYCHEM CRSM

Product Features

-

Voltage Class (kV): ≤ 1

-

Power Cable Wrap Product Type : Sleeve

-

Compatible Cable Diameter (Max) (mm): 21 | 27 | 32 | 43 | 50 | 65 | 68 | 86 | 115 | 120 | 150 | 160 | 200

-

Compatible Cable Diameter (Max) (in): .826 | 1.062 | 1.259 | 1.692 | 1.968 | 2.559 | 2.677 | 3.385 | 4.527 | 4.724 | 5.905 | 6.299 | 7.874

-

Compatible Cable Diameter (Min) (mm): 11 | 17 | 24 | 31 | 32 | 33 | 39 | 56 | 60 | 103 | 105

-

Compatible Cable Diameter (Min) (in): .433 | .669 | .944 | 1.22 | 1.259 | 1.299 | 1.535 | 2.204 | 2.362 | 4.055 | 4.133

-

Flammability Performance : Non-Flame-Retardant

Available from

Our Raychem CRSM Wraparound Sleeve fit easily onto the cable to repair the outer jacket and seal against moisture.

Our Raychem CRSM Wraparound Sleeve for Cable Repair are designed using heat shrink technology. The closure system consists of a raised rail profile and a stainless steel channel that can be installed without any special tools. When heat is applied to the wraparound heat shrink cable jacket repair sleeves, they shrink tightly to the original smaller extruded diameter and to the cable shape. Their hot-melt sealant provides a reliable environmental seal. The Wraparound Sleeve for Cable Repair are halogen-free and stabilized against UV radiation, which ensures long-term reliability in harsh environments.

The Wraparound Sleeves are mainly used as insulation, sealing, or as rejacketing material for 1000V power cables, as well as cable jacket repair for medium voltage power cables and may also be used as protection on various substrates.

Our wraparound system is very easy to install and is particularly suitable when installation space is tight or difficult to reach.

Key Features

- Fast and easy fitting thanks to the channel which can be installed without any special tools

- Reliable closure system and environmental seal with excellent bonding

- Cross-linked polyolefin material, halogen-free and non-corrosive

- RoHS and REACH compliant

- Unlimited shelf-life when stored under normal conditions

- Qualified to ANSI C119.1 and EN 50393:2015

Wraparound Sleeve for Cable Repair

Improving Grid Reliability

Learn how to quickly install TE Connectivity's Raychem CRSM Heat Shrink Repair Sleeve.

Our Raychem Insulation and Protection Solutions

Frequently Asked Questions

Question: For which application can TE’s Raychem CRSM Wraparound Sleeve be used?

Answer: Our Raychem Wraparound Sleeves can be used to repair the outer jacket of the cable and seal against moisture. The closure system consists of a raised rail profile and a stainless-steel channel.

Question: With what type of cable can I use the Wraparound Sleeve?

Answer: Our Wraparound Sleeves are for insulating, sealing or as rejacketing material for 1000V power cables, as well as cable jacket repair for medium voltage power cables. They may also be used as protection on various substrates, where installation space is tight or difficult to reach.

Question: What are the heat shrink Wraparound Sleeves made of?

Answer: The Wraparound Sleeves are made of our Raychem heat shrink material. This specially-formulated medium-wall, cross-linked polyolefin shrinks to its original smaller extruded diameter when heat is applied. The heat shrink material is comprised of polymeric materials exposed to a high-energy electron beam that causes permanent cross-linking, or intermolecular joining, of adjacent molecules. Due to cross-linking, the heat shrink material loses its melting properties allowing it to be heated to temperatures beyond the crystalline melting point without melting. Above this temperature, heat shrink can be expanded and formed in shapes that will remain in position while the temperature decreases below the crystalline melting point again.

When properly installed our Raychem heat-shrinkable repair sleeves are long-lasting products that will help you improve your grid connectivity and reliability for decades.

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Adhesive Coating With

-

Power Component Options Channels & Clips | Channels Included

-

Coating Style Inline

-

Power Cable Wrap Product Type Sleeve

-

Wall Style (Excluding Adhesive) Single

-

Installation Technology Heat Shrink

Electrical Characteristics

-

Voltage Class (kV) ≤ 1

Body Features

-

Primary Product Color Black

-

Primary Product Material Crosslinked Polyolefin

-

Flexibility Semi-Rigid

-

Shrink Ratio >3:1

Mechanical Attachment

-

Mechanical Reinforcement No

Dimensions

-

Compatible Cable Diameter (Max) (mm) 21 | 27 | 32 | 43 | 50 | 65 | 68 | 86 | 115 | 120 | 150 | 160 | 200

-

Compatible Cable Diameter (Max) (in) .826 | 1.062 | 1.259 | 1.692 | 1.968 | 2.559 | 2.677 | 3.385 | 4.527 | 4.724 | 5.905 | 6.299 | 7.874

-

Compatible Cable Diameter (Min) (mm) 11 | 17 | 24 | 31 | 32 | 33 | 39 | 56 | 60 | 103 | 105

-

Compatible Cable Diameter (Min) (in) .433 | .669 | .944 | 1.22 | 1.259 | 1.299 | 1.535 | 2.204 | 2.362 | 4.055 | 4.133

-

Wall Thickness Medium

-

Recovered Wall Thickness (Max) (mm) 1.7 | 1.8 | 2 | 2.1 | 2.4

-

Expanded Inside Diameter (Min) (mm) 34 | 35 | 53 | 54 | 84 | 85 | 86 | 107 | 108 | 143 | 144 | 198 | 203 | 250 | 257

-

Expanded Inside Diameter (Min) (in) 1.338 | 1.377 | 2.086 | 2.125 | 3.307 | 3.346 | 3.385 | 4.212 | 4.251 | 5.629 | 5.669 | 7.795 | 7.992 | 9.842 | 10.11 | 10.118

-

Recovered Inside Diameter (Max) (mm) 9 | 10 | 13 | 15 | 20 | 21 | 27 | 28 | 29 | 36 | 50 | 55 | 91

-

Recovered Inside Diameter (Max) (in) .354 | .393 | .511 | .59 | .787 | .826 | 1.06 | 1.1 | 1.14 | 1.41 | 1.96 | 2.16 | 3.58

-

Product Length (mm) 150 | 200 | 250 | 300 | 350 | 375 | 400 | 500 | 600 | 650 | 750 | 870 | 1000 | 1200 | 1500 | 2000

-

Product Length (in) 5.905 | 7.874 | 9.842 | 9.846 | 11.811 | 13.779 | 14.763 | 15.748 | 19.685 | 23.622 | 29.527 | 29.59 | 34.251 | 39.37 | 47.244 | 59.055 | 78.74

Usage Conditions

-

Fluid Resistance Type Hydrocarbons | Transformer Oil

-

Environmental Resistance Contaminated Water | Moisture | Rain | Salt Water | Water-Blocking | Weathering

-

Flammability Performance Non-Flame-Retardant

Operation/Application

-

Mechanical Resistance Against Mechanical Impact | Against Mechanical Impact or Damage

-

Thermal Resistance Applicable for High Temperatures | Applicable for Low Temperatures

-

Power Component Application Type Underground

-

Marine-Offshore-Shipbuilding Certified No | Yes

-

UV-Stabilized Yes

Industry Standards

-

Compatible With Approved Standards Products ANSI C119.1 | EN 50393 | HD631.2 | IEC 60684-2 | IEC 60684-3-214 | IEC 60684-3-246 | IEC 60684-3-247

Product Availability

-

Product Availability Worldwide

Other

-

Product Use Cable Jacketing | Cable Jacket Repair

Reference Number

-

TE Internal Number CAT-CRSM

Datasheets & Catalog Pages

- CRSM WRAPAROUND SLEEVES IEC pdf German

- CRSM WRAPAROUND SLEEVES IEC pdf English

- CRSM WRAPAROUND SLEEVES IEEE pdf English

Are you sure you want to close chat?

To begin your chat with TE please enter your details