Trend Insight

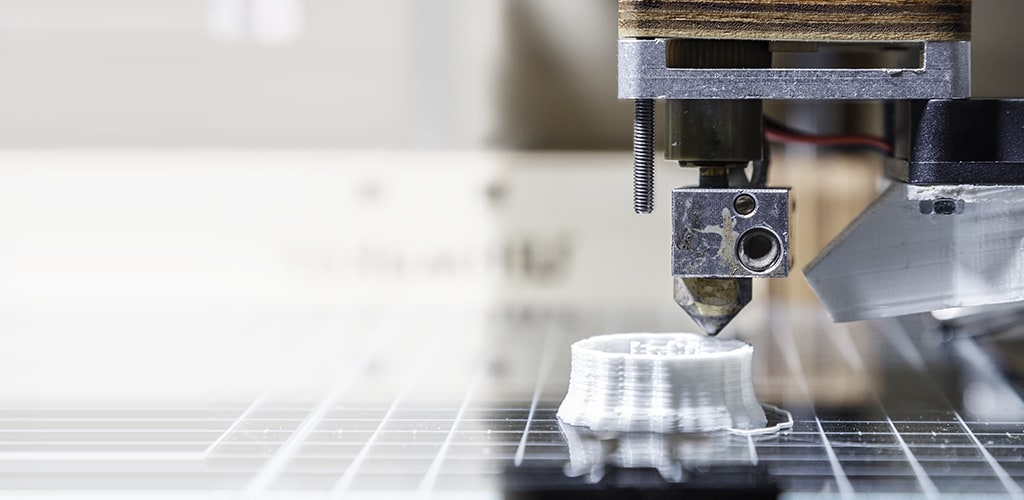

Future: Platforming and 3D

Platforming offers many benefits to customers, including higher quality and faster time-to-market.

Platforming:

The Original Recycle Bin

To offer customers design flexibility and faster time-to-market, we use platforming, the reuse of our tooling components. Egbert Stellinga, our product manager for mobile I/O products, says, “We are moving more toward manufacturing systems that will help us build connectors with structures like interchangeable toy blocks.”

Doing all this work online might be utopia, but I would like to see it happen in the next five years. I think this is possible.

- Egbert Stellinga,

- Product Manager, Mobile Input/Output

Survey to Prototype

In Less Than 60 Minutes

Stellinga imagines the TE customer being able to go to TE.com and answer a few questions. The questions would be used to generate a 3D model, and the file for that model could be sent to a 3D printer anywhere in the world for hands-on review. “Our A/V platform is quite far along in this way—we have identified the common building blocks customers can ‘shop’ for.” Using the customer’s selection, the engineer creates the 3D model for the new audio/visual jack. Stellinga says that today, prototype creation sometimes can take as little as 30-60 minutes.

Trend Insight

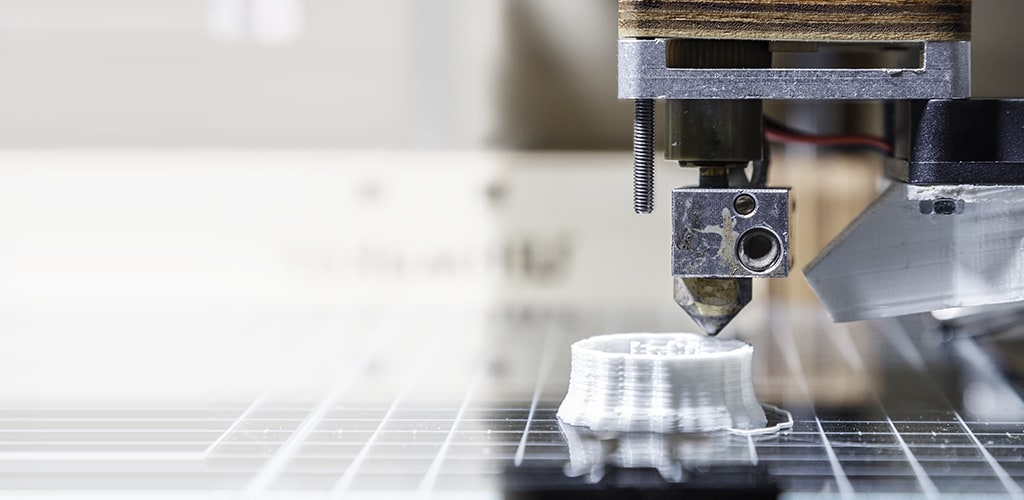

Future: Platforming and 3D

Platforming offers many benefits to customers, including higher quality and faster time-to-market.

Platforming:

The Original Recycle Bin

To offer customers design flexibility and faster time-to-market, we use platforming, the reuse of our tooling components. Egbert Stellinga, our product manager for mobile I/O products, says, “We are moving more toward manufacturing systems that will help us build connectors with structures like interchangeable toy blocks.”

Doing all this work online might be utopia, but I would like to see it happen in the next five years. I think this is possible.

- Egbert Stellinga,

- Product Manager, Mobile Input/Output

Survey to Prototype

In Less Than 60 Minutes

Stellinga imagines the TE customer being able to go to TE.com and answer a few questions. The questions would be used to generate a 3D model, and the file for that model could be sent to a 3D printer anywhere in the world for hands-on review. “Our A/V platform is quite far along in this way—we have identified the common building blocks customers can ‘shop’ for.” Using the customer’s selection, the engineer creates the 3D model for the new audio/visual jack. Stellinga says that today, prototype creation sometimes can take as little as 30-60 minutes.