Forming lasting bonds

Dedicated to delivering a higher standard for medical device OEMs, our goal is to form lasting bonds with the world’s leading medical technology brands to build medical devices that saves lives.

Contract design and manufacturing outsourcing (CDMO) partners play a critical role in the medical device supply chain. Medical device companies increasingly rely on outsourced development and manufacturing to access innovation and specialist technologies at scale with the added benefit of improved cost and operational efficiencies. Successful OEM and CDMO relationships are enduring, built on high-trust partnership models founded in know-how. In an increasingly competitive MedTech market, medical device companies demand partners who can maintain high quality standards, competitiveness, and technical expertise on a global scale. Partners with the highest degree of vertical integration and widest global reach will spearhead this structural transformation, including TE Connectivity.

By working with us, you get more than just a component supplier. You get an integrated solutions partner who can develop your idea from design to prototype and volume manufacturing.

Integrated Solutions Partner

The value we provide helps you compete, including:

- Engineering expertise: early design collaboration takes you from concept to production, and more

- Extensive manufacturing capabilities: we create components or fully functional devices where and when you want, including contract manufacturing

- Global footprint: get better responsiveness and access to emerging markets

- Focus on the end user: we design for ergonomics, small spaces, high speed, high performance and reliable connectivity

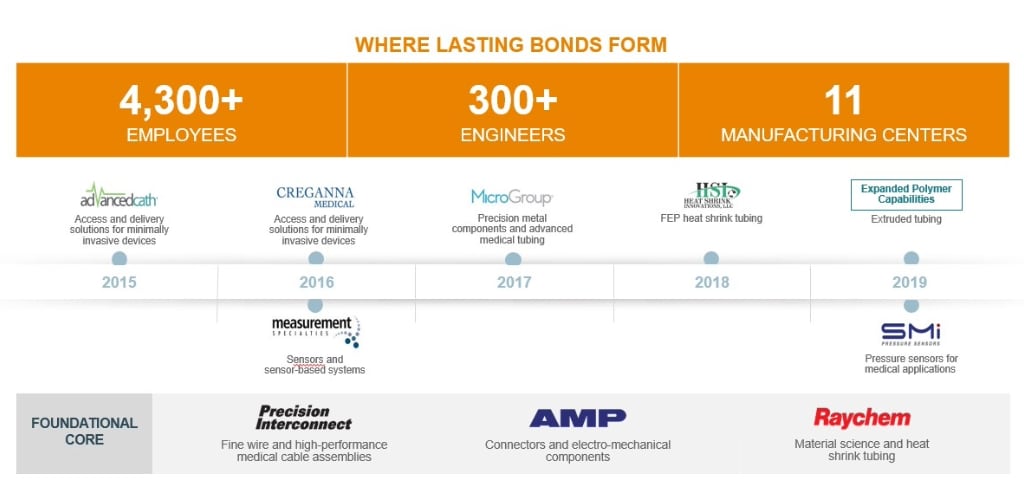

4,300+

Employees

330+

Engineers

14

Global R&D and manufacturing centers

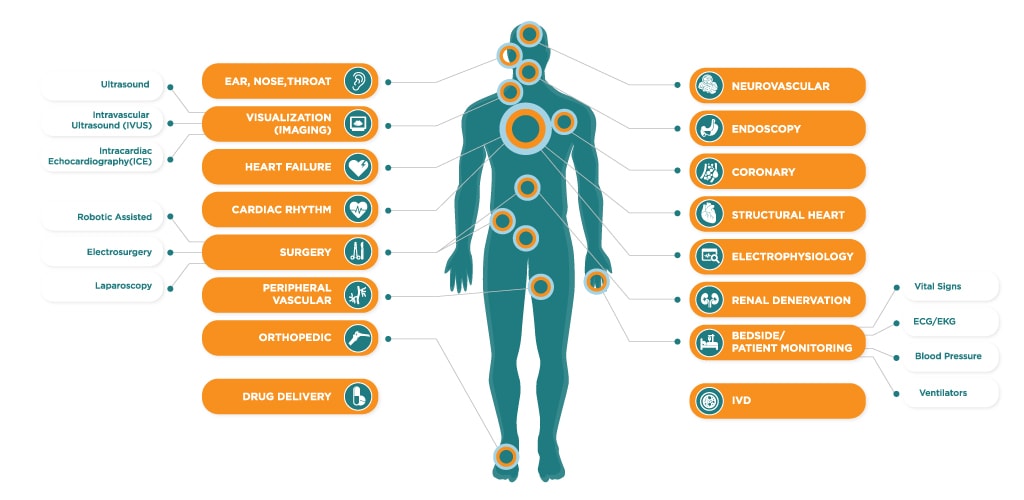

An essential component in turning your ideas into reality at speed. We provide top-tier engineering and manufacturing expertise to help our customers innovate and manufacture key components and minimally invasive medical device solutions for various healthcare specialties/procedures.

Over 60 years of medical innovation and transformation. We’re continuously building on a legacy of innovation with each new portfolio addition to better serve our MedTech customers.