Voltage Output Comparison

Compare the differences of some of the more popular analog voltage output signals available for pressure transducers.

Pressure Transducers are available with a variety of voltage output options. With advances in controllers that receive the transducer signal, there is more flexibility in the marketplace. There are minor differences between many of the output options on the market place. While some developed to maintain competitive advantages via customized products, others have solid reasoning. The outputs reviewed here are all powered by a minimum of 10VDC (0-10V and 1-10V outputs need 12VDC). A 0.5-4.5V ratiometric output signal is traditionally powered by a 5VDC regulated supply, yet other variations are possible. In a similar way, millivolt output signals have their own unique features and benefits. The following is a brief introduction to amplified voltage pressure transducers.

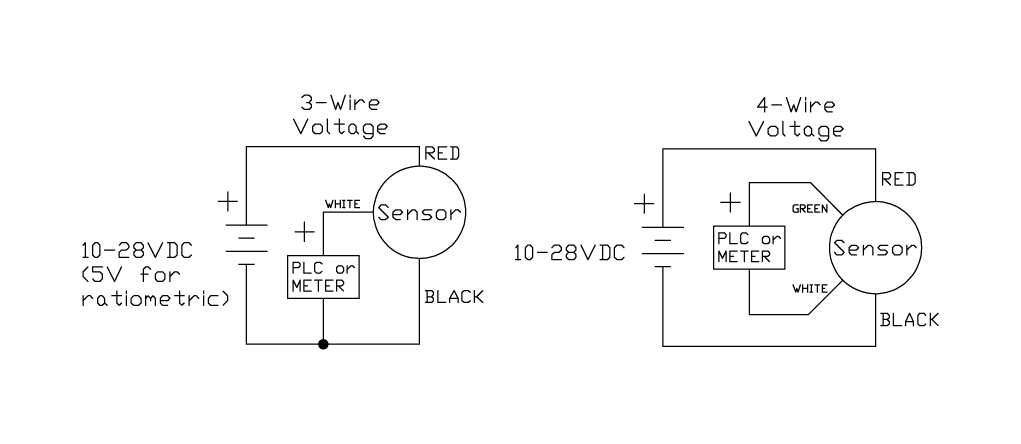

ZERO BASED OUTPUTS

Traditional pressure transducer outputs include 0-5V and 0-10V signals. Popularized in Europe, zero based output signal produce no output signal at zero pressure in a standard gauge pressure transducer. Transducers are offered in three wire and four wire configurations with zero based output signals. The advantage of the 0-10V signal is that it has twice the span as the 0-5V. The main disadvantage to any zero-based output signal is that there is no signal with zero pressure. If the transducer has a cut wire, broken sensing element, or electronics that received an over-voltage, the sensor will produce no signal, thus no way to know of a problem. If we assume that the pressure transducer is measuring water pressure, it will produce a 0V signal when there is no pressure in the line. When pressure is sensed, it will signal the pump to act. Since the sensor at 0V is the same in fault conditions and at no pressure, there is no way to distinguish between the two. The pump would not know to run, and could cause a flooding condition.

VOLTAGE AT ZERO PRESSURE

There are many variations and custom options for pressure transducers with an output signal at 0 PSI. For example, TE offers 1-5V, 1-6V, 0.25-5V, and 1-10V. The 1-5V output signal is most popular in the industry. There is the safety feature of having a 1 volt output signal at zero pressure and a 4 volt span for pressure measurement. 1-6V and 1-10V output signals are popular among engineers who prefer a voltage span similar to the zero based outputs above, but with the signal at zero pressure. The 0.5-2.5V output signal is somewhat unique. For remote telemetry applications, current consumption is a common factor. Because lithium-ion batteries or solar panels create power in remote oil fields and on construction site equipment, having a low power supply voltage and low current consumption extend the service life of the pressure transducer. The 0.5V 0PSI signal gives enough indication that the transducer is working. The span to 2.5V gives enough resolution to accurately measure the pressure or level.

SMARTER SENSORS

Industrial pressure transducers are becoming smarter. With advances in electronics and microprocessors, pressure transducers are available with a factory set "fault condition." The transducer can be programmed to "rail" or send the output below the lowest point or above the highest point to indicate to the controller that there is an issue. For example, if a pressure spike in the system causes the sensor diaphragm to break, the output signal on a 1-5V output signal can be programmed to drop the output below 1V or above 5V (by about 10%). In a pump application, it can help prevent flooding, the pump from running dry, or extra wear.