Applications are getting smaller but connectors are being asked to do more. Connectors need to reach a higher power and provide flexibility in modular, hybrid solutions. Learn more about how TE Connectivity’s Heavy Duty Connectors get the job done for your application needs in this video.

Heavy Duty Connectors

Heavy Duty Connectors (HDC) are industrial connectors designed to transmit power, data and signal in the toughest of conditions. In environments with vibrations, risk of dust, temperature challenges and mechanical impact, our HDC connectors provide a reliable solution with solid aluminum or thermoplastic hoods and housings with protection degree from IP65 up to IP69k. Approved according to EN/IEC 61984 standard, our HDC connectors range from 10A to 650A, and are available with up to 288 contacts.

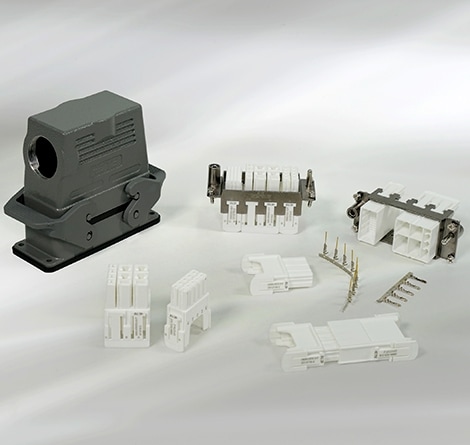

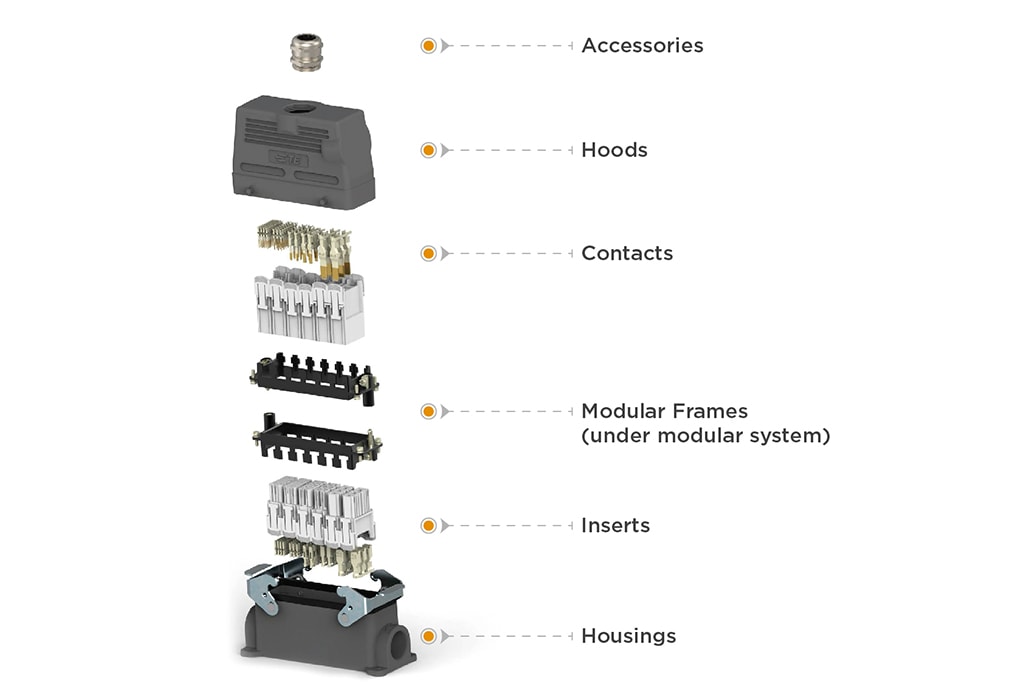

HEAVY DUTY CONNECTORS SYSTEM

We offer a vast portfolio of heavy duty rectangular power connectors as well as signal connectors to suit many application needs. In the indoor applications, try the lightweight and safe thermoplastic enclosures, saving space and installation effort. High performance inserts provide standard and high density contact configurations, with electrical performance ranging from 2.2A @ 32V up to 650A at 12kV. Reliable lose-piece screw machined contacts and cost efficient stamped & formed contacts on the reel are available for crimp, screw and cage clamp termination and offered in gold, silver, tin and palladium plated options. Space saving hybrid connectors make power, signal and data transmission possible in a single connection, and HMN modular system will make interface customization as easy as the use of building blocks can be.

TE has been producing Heavy Duty Connectors (HDC) for over 60 years. The portfolio includes one of the best in quality and sustainability, helping you to reduce go-to-market time. Featuring a modular design, TE HDCs fit perfectly in our one-piece frame, to make installation more convenient and time-saving.

With the broad portfolio of Heavy Duty Connectors, TE Connectivity offers a reliable solution for industrial applications in the harshest environments, from rail to the factory. The modular concept of these connectors provides a flexible and quick adaption to the requirements of your application.

TE introduces the newest upgrade - HDC TIC-LOQ Technology. HDC with TIC-LOQ technology features a self-locking system, fitting with metal enclosures, IP65 water protection, and compatibility with a standard HDC portfolio. Choose from a variety of inserts from 2 pins to 32 pins in a single module allowing for both power and signal transfer with current available from 2.2 amps to 40 amps.

Heavy Duty Connector Portfolio

HQ-4/4/6 HYBRID INSERT WITH CAT5 ETHERNET

TE Connectivity (TE) HDC introduced an HQ insert with a hybrid design, the Hybrid Insert involves power, signal and Ethernet data transmission functions. The ethernet data module with EMC shielding provides high-quality data with CAT5 speed. The latest solution helps enable connection reliability and higher accuracy.

HDC H3A TIC LOQ CONNECTOR SYSTEM

TE Connectivity's (TE) HDC H3A TIC LOQ Connector System helps enable us to provide operator-friendly locking connectors. With introduction of this latest H3A TIC-LOQ housing, it is possible to perform automatic mating with H3A Hood. The process will bring to save process time and will contribute to customer satisfaction. This TIC-LOQ Housing is compatible with series of standard HDC HQ Insert. HQ-D-032 Insert has been released at the same time. It can be used with TIC-LOQ Housing. It is a high density design with 32 contacts in the Insert and will contribute to space -saving in various applications.

HPC 200A CONNECTOR

TE Connectivity (TE)’s HPC Series focuses on Battery Energy Storage System (BESS) to provide a high safety and reliability solution with one pole 200A/1500V high current connector. Bringing the one-piece molding contact, the HPC 200A Connector provides excellent temperature rise control capability. Meanwhile, the HPC 200A Connector is installed with a high-performance temperature sensor (optional) to enable 24Hrs system safety monitor. The smart locking system with 180° in-line design, provides 360° rotation, 12 angles of locking with each 30° degrees, quick lock, and press to release function to enable convenient and fast assembly of large volume connectors on site.

TE Connectivity (TE)’s HPC Series focuses on Battery Energy Storage System (BESS) to provide a high safety and reliability solution with one pole 200A/1500V high current connector. Bringing the one-piece moulding contact, the HPC 200A Connector provides excellent temperature rise control capability.

HPC 350A BESS CONNECTOR

TE Connectivity (TE)’s HPC Series focuses on Battery Energy Storage System (BESS) to provide a higher safety and reliability solution with one pole 350A/1500V

high current connector. Bringing the one-piece molding contact, HPC 350A the connector provides excellent temperature rise control capability. Meanwhile, HPC 350A connector installed with a high-performance temperature sensor (optional) to support 24-hour system safety monitor. The smart locking system with a 180° in-line design, provides 360° rotation, quick lock and press-to-release function to support convenient and fast assembly of large volume connectors on site.

HDC FLOATING CHARGE CONNECTOR FOR AGV CHARGE

TE Connectivity (TE) Heavy Duty Connectors (HDC) now offer the HDC Floating Charge Connector for the Warehouse Automation application. This charging connectors innovative technology has excellent capability with up to 30,000 mating cycles to provide a highly reliable solution. Its clever floating system helps enable Autonomously Guided Vehicles(AGV) to automatically correct mating positions. Additionally, its compact design with hybrid power and signal helps enable the miniaturization of vehicles. TE HDC floating charge connector focuses on providing your AGV/AutonomousMobile Robot (AMR) with a higher efficiency, more reliable, and size-reduced solution.

TE Connectivity (TE) Heavy Duty Connectors (HDC) now offering the HDC Floating Charge Connector for Warehouse Automation application. This charging connector's innovative technology has excellent capability, with up to 30,000 mating cycles to provide a highly reliable solution. Its clever floating system helps enable Autonomously Guided Vehicles (AGV) to automatically correct mating positions.

BESS STACKED HYBRID CONNECTOR

TE Connectivity, a global leader in connectivity and sensing, introduces the new product of Heavy Duty Connectors, the HDC BPSC Stacked Hybrid Connector for BESS Battery Energy Storage application. With its smart hybrid design, it provides a safer, more reliable and more flexible residential BESS power & signal stacked connectivity connection.The new generation of BPSC hybrid stacked connector uses materials with excellent electrical conductivity and composite terminal technology. It provides outstanding terminal conductive efficiency and excellent lower temperature rise control. This supports the safety and reliability of the system’s life cycle.

Frequently Asked Questions (FAQs)

What is a Heavy Duty Connector (HDC)?

An HDC connector is a rectangular, robust industrial connector designed to transmit power, data, and signals in harsh environment applications.

What are the appropriate applications for Heavy Duty Connectors (HDC)?

Typical applications include robotics, automation, machinery, rail, and power applications.

What products does the Heavy Duty Connector (HDC) portfolio consist of

The HDC portfolio consists of:

- Hoods, housings, and bases: available in different protection degrees IP65, IP67, IP68, and IP69k.

- Contact systems: ranging from 5A to 650A in the screw, crimp, and cage clamp termination.

- Inserts: available in up to 216 pins in one connector for crimp, screw termination, or cage clamp.