High Vibration Connectors and Contacts for Engine Applications

Driven by the need for increased fuel efficiency and CO2 emissions reduction while improving performance, the next generation of internal combustion engines in passenger cars is characterized by their reduced size, increased power and engine speed (RPM). However, the higher vibration behavior of these new engine designs means that electrical connectors, that connect the electronics components within the engine bay, require new levels of vibration resistance not provided by standard connectors traditionally deployed in such applications.

SG 6

Designed for SG 6 (LV 214) vibration resistance

150°C

Operating Temperatures up to 150°C

IPx9K

IP rating for harsh environments

Engine bay applications

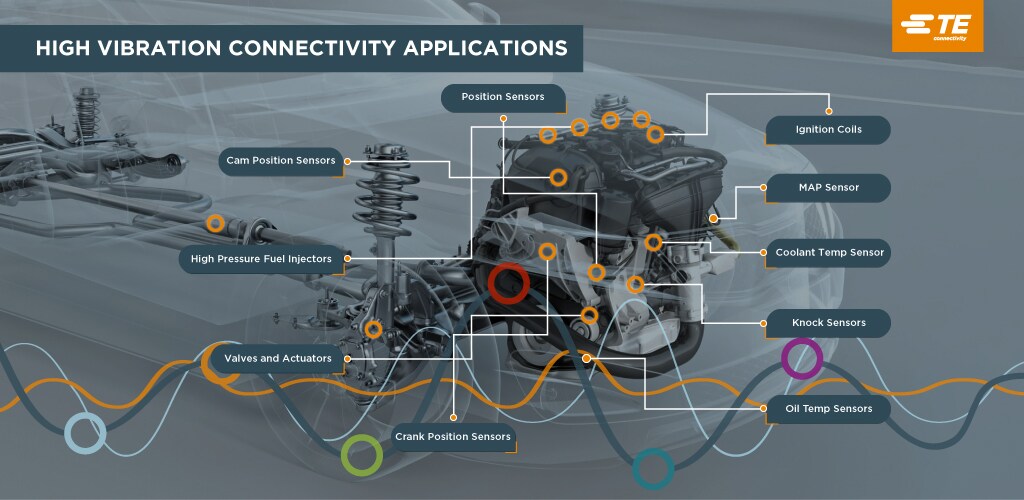

Engine bay connector applications require a high level of robustness ensuring reliability throughout the lifetime of the vehicle. That means a fully sealed design capable of operating in temperatures up to 150°C and up to Level 6 vibration and be certified against the strictest automotive standards such as LV214. It is critical that connectors and contacts be designed to avoid movement and surface layer destruction of the contact points.

This should include:

- Minimization of connector movement at the connection interface

- Avoidance of relative movement of the contacts

- Reduction of cable movement

HPF 1.2 Terminals

TE Connectivity’s HPF 1.2 contact system which accommodates 1.2mm x 0.6mm tabs, is a flat terminal designed specifically to address high vibration and temperature applications in the vehicle engine bay. It is designed to avoid micro movements caused by vibration at the points of contact. This is achieved by the contact zone being mechanically decoupled from the remaining terminal body and by the application of higher normal force to the point of contact. A crimp-type connection is designed for connecting cables with cross-sections ranging between 0.35 mm² and 1 mm².

A “meander” shaped geometry is designed to minimize micro movements introduced in the axial direction through the cable.

Benefits

- ‘Meander’ design minimizes external forces and movement

- Level SG6 (LV214) in conjunction with HPF 1.2 connectors

- Fully validated to LV214

- High performance copper alloy for sustained performance throughout lifetime

- High normal force for better contact with PCB

- Ultra-high-performance flat terminal for high vibration and high temperature environments

- Multiple contact points for high vibration capability

- Large wheelbase at contact

- Highly suitable for engine compartment applications

- Single Wire Seal (SWS) Design - new seal isolates wire-transmitted vibration away from the terminal

- Suitable for tab size 1.2 x 0.6mm

HPF 1.2 Connectors

The housing has been adapted to the contact in a number of ways in order to decouple the contact zone from the introduced movements realized in the HPF 1.2 to create an optimal effect. These effects include accuracy of fit in the contact cavity and a specific 20% longer special radial wire seal to prevent relative movements in the contact points. With its good damping properties, the housing material also contributes towards the overall performance of the connector system.

Benefits

- Sealed design

- Standard housings -40°C to 150°C temperature range (Up to 180°C housings available on request)

- Level 6 (LV214) when deployed with HPF 1.2 terminals

- Connector minimizes interface free play in both long and short shroud versions

- Interface-compatible with the MCON 1.2

- Up to 48V - ready for 48V architectures

- Connector Position Assurance (CPA) and terminal retainer for reliability and security

- Minimization of connector movement at the connection interface

- Reducation of cable movement

- Vibration resistance 4x higher than most stringent vibration requirements specified today