Maximize Quality, Yield and Savings

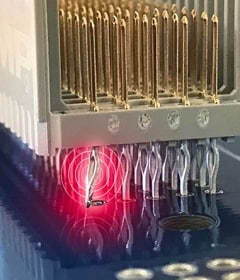

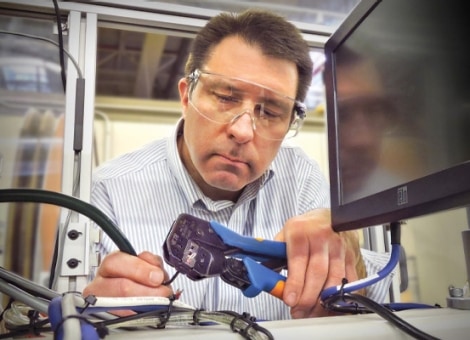

Our connector seating machines process compliant pin connectors and can handle the most demanding applications from daughter cards to mid-planes and back-planes. Our premier compliant pin, solder-free insertion press fit machines offer quicker, more reliable and less operator intensive processing. Fast, simple product presentation with full control and monitoring of force, distance and speed results in higher quality, improved yield and greater cost savings. Plus, each press is programmed and run via a PC with all product, tool and process information conveniently stored in a database. When operating the press fit machine, all necessary adjustments to the press stroke are completed automatically without intervention. Imagine how much scrap and rework from common operator errors this will prevent.

Features

| Model | Pressing Force | Est. Speed Cycle | System Type | Programmable |

|---|---|---|---|---|

| CBP-5T MKII | 5 Tons [44 kN] |

3-5 sec/ connector | Semi-automatic press, bench-top | Yes |

| CMP-5T MKII | 5 Tons [44 kN] |

3-5 sec/ connector | Automatic press, standalone | Yes |

| CMP-10T MKII | 10 Tons [88 kN] |

3-5 sec/ connector | Automatic press, standalone | Yes |

| CSP-5T MKII | Up to 5 Tons [44 kN] |

6-8 sec/stroke incl. shuttle of product | Semi-automatic press, standalone w/shuttle | Yes |

| AP-3T | Up to 3 Tons [29 kN] | Depends on requirements of application | Automatic press, standalone | Yes |

| AP-5T | Up to 5 Tons [44 kN] | Depends on requirements of application |

Automatic press, standalone | Yes |

Applications

Printed Circuit Boards (PCB's)

- Daughter cards

- Mid-planes

- Back-planes

- Low to medium production volumes

Typical Application in Industries

-

Aerospace

CBT-5T MKII

-

Automotive

CSP-5T MKII

-

Data Centers

AP-3T/5T, CBT-5T MKII, CMP-5T MKII, CMP-10T MKII, CSP-5T MKII