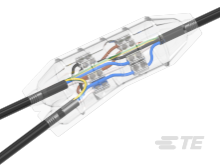

TBJ joints are designed for simplicity and easy installation. They are part of TE’s cable accessories range, known for more than 60 years for its expertise, reliability, and quality. Clear rigid high-impact polystyrene joint shells provide generous jointing dimensions and allow easy viewing to check connector positioning and resin filling. The joint shells are supplied complete with pre-applied foam sealing strips, fixing clips and sealing tape. Filling the joint is made easier with a convenient pouring funnel and sealing cap.

All joints are supplied with TE Connectivity range of B&H mechanical connectors. These connectors come complete with moulded insulation shrouds which offer reliable and robust insulation reducing installation time and making live working easier and safer.

For applications above 70 mm2, the kits complete with shear-controlled mechanical connectors suitable for stranded, solid, sectoral and round conductors.

Components for armour bonding are included in the kit. The continuity bond is an insulated flexible conductor with short circuit rating suitable for fuse-protected circuits.

Joints are filled with a qualified and well-established resin, with the option of either two-part polyurethane resin or

Guroflex-N™ environmentally friendly resin. Each option is supplied in flexible foil laminate pouches for easy mixing and pouring. Resin kits carry a full 2-year shelf-life.

Each joint kit includes clear and detailed installation instructions. Kit components are well protected in robust box packaging with clear labelling.