-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Overview

This product is not currently available. For more information, including distributor inventory, please contact us.

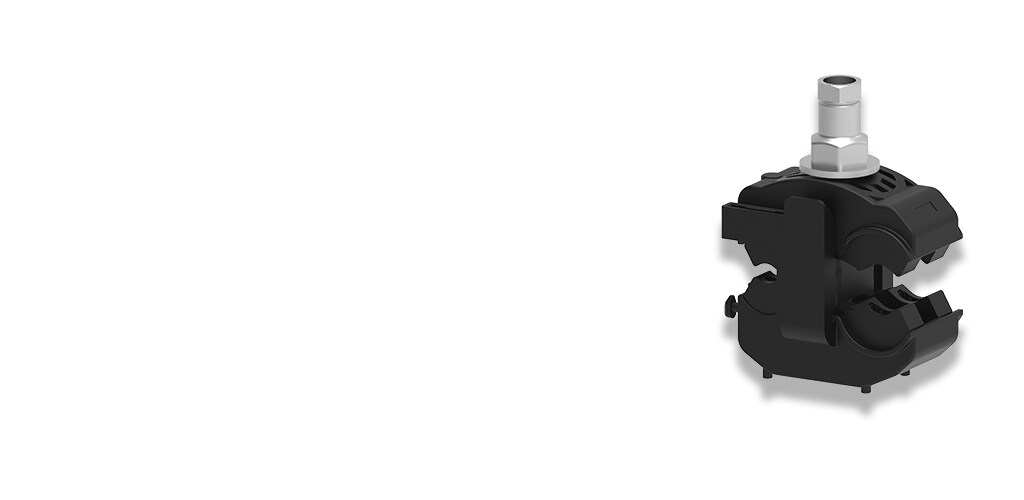

Insulation Piercing Connector for Solar Farm Applications

Product Features

-

Solar Connector Type : PV connector

-

Solar Connector Style : Piercing

Available from

Build and price the product now

Overview

Our P2S Solar Insulation Piercing Connectors are designed to be installed in utility-scale solar plants using DC trunk-bus system.

Our P2S 240 Solar Insulation Piercing Connectors are engineered for the DC trunk bus system to connect the main side (double insulated stranded (class II) aluminum cables from 70 to 240 mm²) to tap side (double insulated flexible (class V) copper cables from 6 to 35 mm²) in operating temperature from -55°C to +°55°C. The P2S 40 solar connectors are made with UV-stable and impact-resistant plastic raw materials.

The P2S 240 connectors provide protection, insulation, and high-quality sealing of the electrical connections thanks to the Insulation Piercing Technology (IPC) that doesn't require stripping the conductor insulation before making the connection.

Metallic blades surrounded with a sealing compound ensure electrical contact for PV cables up to 1.5 kV DC. A single torque control nut draws the two parts of the connector together and shears off when the teeth have pierced the insulation and made contact with the conductor strands. The connection made by the P2S 240 on solar cables is totally watertight thanks to the elastomeric seals.

Shear bolts always guarantee the optimum contact force without the use of a torque wrench or other special tools.

The solar Insulation Piercing Connectors have been successfully tested according to EN 50483-4 and according to some specific tests defined in IEC 62852.

In order to meet protection class II, a Powergel box can be added over the IPC (GIPC-500). The GIPC-500 enclosure, with Powergel sealant, protects and seals the connection quickly and easily, saving both time and effort. The Powergel sealant is rated to 90°C continuous temperature and is halogen-free with an extended shelf life.

Key Features

- Range taking

- Waterproof (6.5 kV under 30 cm for 5 minutes)

- Protection degree: IP68

- Glow wire test at 650°C

- Installation temperature -10°C to +55°C

- Flame retardant property: HB according to UL94

- Extremely low leakage current

- Adjusts to connection spacing on-site with convenient flexibility

P2S 420 Solar Insulation Piercing Connectors

Improving Grid Connectivity

FAQ

Frequently Asked Questions

Question: Which type of solar farm is TE’s Solar IPC P2S 240 designed for?

Answer: Our P2S 240 is specifically designed for solar farms using a trunk bus system. It will connect the bus cable (main side) to the jumper cables (tap side). It can be installed on PV cables up to 1.5 kV DC.

Question: What is the difference between the solar farms using a conventional method or the trunk bus system?

Answer: With a conventional system, each panel string is connected to the Combiner box (including fuses) using a jumper cable (4 to 16 mm²). With the trunk bus system, each panel string is connected to a Bus cable (70-240 mm²) thanks to our Insulation Piercing Connector (P2S 240). The strings are protected using an over-molded fused harness.

The Trunk Bus system is designed to reduce material and labor costs during installation, and ultimately improves the efficiency of the DC grid system:

- Length of jumper wires reduced up to 50% with reduced voltage losses thanks to bigger sections (cost reduction)

- Reduce installation time allows more flexible farm design

- Over-molded fused harness eliminates the need for combiner boxes

Question: Why is TE’s Solar IPC P2S 240 different from the other IPCs already available?

Answer: Our solar IPC P2S 240 has been specially designed to connect PV cables up to 1.5 kV DC using double insulated stranded (class 2) aluminum cables for the bus cable and double insulated flexible (class 5) copper cables for the jumper cables.

The P2S 240 meets the specific solar requirements regarding protection and insulation performance (degree of protection IP68, voltage test underwater at 6.5 kV for 5 min, impulse withstand test) and specific raw material features (glow wire test at 650°C, flame retardant property HB according to UL94).

The P2S 240 will help you achieve high-quality electrical contact by piercing the double insulation layers without affecting the mechanical performances of the flexible solar conductors at the tap side.

Question: Is a specific tool needed to install TE’s Solar IPC P2S 240?

Answer: No, the installation of our P2S 240 can be done using a spanner 13 mm A/F.

Question: Is any cable preparation needed before installing TE’s Solar IPC P2S 240 on solar cable?

Answer: Thanks to Insulation Piercing Technology (IPC), no specific cable preparation is required such as cable stripping, before mounting the connector. The installer must only make sure that the insulation jacket of the connected cables is clean before connecting the IPC.

Features

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Piercing Blade Base Material Tinned Copper

-

Solar Connector Type PV connector

-

Solar Connector Style Piercing

Electrical Characteristics

-

Voltage Class (kV) ≤ 2

Operation/Application

-

Power Component Application Type Overhead

Product Availability

-

Product Availability Europe, Middle East & Africa

Packaging Features

-

Packaging Quantity 50

Reference Number

-

TE Internal Number CAT-P2S-240

Related Materials

Datasheets & Catalog Pages

- SOLAR INSULATION PIERCING CONNECTORS P2S 240 pdf English

Are you sure you want to close chat?

Chat

To begin your chat with TE please enter your details