Trend Insight

Evolution of Medical Sensor Design

As the connected medical industry continues to grow, sensor technology design evolves to meet the demanding needs. Explore these five considerations for non-contact medical applications and review key trends.

As new developments in personal devices and medical equipment are established, sensor technology continues to evolve to meet the demanding needs of the growing connected medical industry. With trends such as Internet of Things (IoT) and enhancements in data analytics and artificial intelligence, sensors are becoming more crucial to collect accurate data. To collect this critical data, invasive and non-invasive sensor technology can be used. Invasive sensors are designed for applications such as arterial blood pressure monitoring during surgical procedures and temperature measurement through micro-thermocouples in catheter assemblies. These sensors require specialized compatibility and packaging, typically in a miniature disposable package. Non-invasive and non-contact sensor technologies have a broader use-case and have both mechanical and electrical design considerations to support the growth in medical devices and equipment. In this article, we will explore these sensor design considerations for non-contact medical applications and review key trends to keep in mind.

SURVIVABILITY

One of the first essential concepts to consider is the survivability, or ruggedness, of these devices. The sensing elements that measure properties such as temperature, vibration, and position are relatively small and delicate. For example, a thermopile sensor is comprised of a precise array of miniature thermistors to measure the temperature within its field of view. These sensors are packaged in a way to protect the sensing element from external environments. This becomes crucial in applications such as ventilation equipment, where a thermopile is designed to measure surface temperature and mass airflow sensors measure the airflow temperature to compensate for condition changes and provide a baseline temperature measurement for other sensors on board. Encapsulated in a stainless-steel housing, the sensing element is hermetically sealed to protect against external conditions such as humidity and other harsh factors.

Similarly, sensors can be packaged within an assembly through non-contact measurement for position sensing.

The demand for Anisotropic Magneto-Resistive (AMR) position sensors has increased with its ability to be packaged and sealed within a device while measuring a magnetic scale external to the assembly. Prosthetic joints are an interesting example. Within this application, AMR sensors can measure rotation of a joint such as a knee or ankle to compensate for movement and create a more natural gait pattern. Since the sensor is packaged within the knee assembly, it protects it from the environmental conditions such as water, impact, and general wear. Therefore, it allows independent rotational movement between the sensor and moving limb without physical contact.

Packaging sensors and electronics in sealed assemblies addresses sterilization concerns. Sterilization in medical applications can be accomplished in a variety of ways including the use of steam or exposure to ethylene oxide. With a sensor encapsulated within a device, it is protected against extreme temperatures or moisture at the component level. Non-contact sensors used for motion control has the ability to be installed in assemblies with the sensor submerged in non-conductive hydraulic oil. This further allows the sensor to be embedded within the assembly without external components exposed. Wearable devices can also exposed to elements in daily life including sweat and chlorinated water. While both elements seem harmless, electronic devices and sensors could experience corrosion issues and electrical shorts if not properly protected. To protect against these conditions, specialty coatings can be applied to sensing devices while still allowing for accurate detection and measurement.

MINIATURIZATION

Another major trend to consider in the sensors industry is miniaturization, an effort to limit a sensor’s required ‘real estate’ within a product. With the increase in wearable, connected devices, the ability to create lightweight, compact designs becomes necessary. Even though watches, chest-mounted heart rate monitors, and jewelry are monitoring health factors with varying accuracy, they are providing more information than was available in the past. As the consumer focus on healthy living grows, the drive to have more precise data increases sensor demand and the need to fit more sensors into the same size package.

Beyond healthy living wearables, miniature sensors can be built into electronic robotic prosthetics. The force and control of fingers require meticulous skill with precise measurements. When considering force measurement, the difference between holding a grape and crushing it can be significant; therefore, it demands accurate data for the fingers to perform seemingly simple tasks. Applying magnetic sensors to the finger joints at the point of rotation and strain gauges allow for the precise contactless control and movement needed.

DIGITAL SIGNAL PROCESSING

Greater accuracy is a key objective in choosing a sensor for medical applications, which makes digital sensors more desirable due to their more precise and robust outputs. For example, digital thermopile temperature sensors can deliver high accuracy ±1°C readings of temperature ranges from 0° to 100°C. When customized to accommodate a wider range of applications for intensely harsh environments, these sensors can deliver high accuracy of ±4.5°C at 300°C. While analog products are often less expensive, digital sensors, by virtue of their design and configuration, do not require the purchase of additional electrical components including low offset/low noise amplifiers and associated filters. Certain sensor technologies, when packaged with digital outputs, can offer multiple output signals from the same device, thus eliminating the overall platform and real estate of the circuit board. Sensors can be designed for more consumer-based medical devices by adopting digital signal processing. This would allow for lower current consumption, the capability to ‘sleep’ while not in use and operate with lower supply voltages which would enable the use of smaller batteries on board.

DIGITAL SIGNALS & SCALABILITY

Digital signal processing plays a role in scalability, which is a fundamental consideration. Traditional analog output signals require some level of conversion for modern electronics to read and process the data. However, on-board digital signal processing reduces the calibration time during system or device manufacture which leads to greater accuracy. Since the sensor manufacturer’s calibration equipment is designed to test and qualify the sensor, it requires less investment by the OEM to duplicate the system requirements to manage the signal processing from analog to digital. In addition, sensor manufacturers can customize mechanical tooling, sensor programming, and calibration to customer requirements to enable plug and play designs.

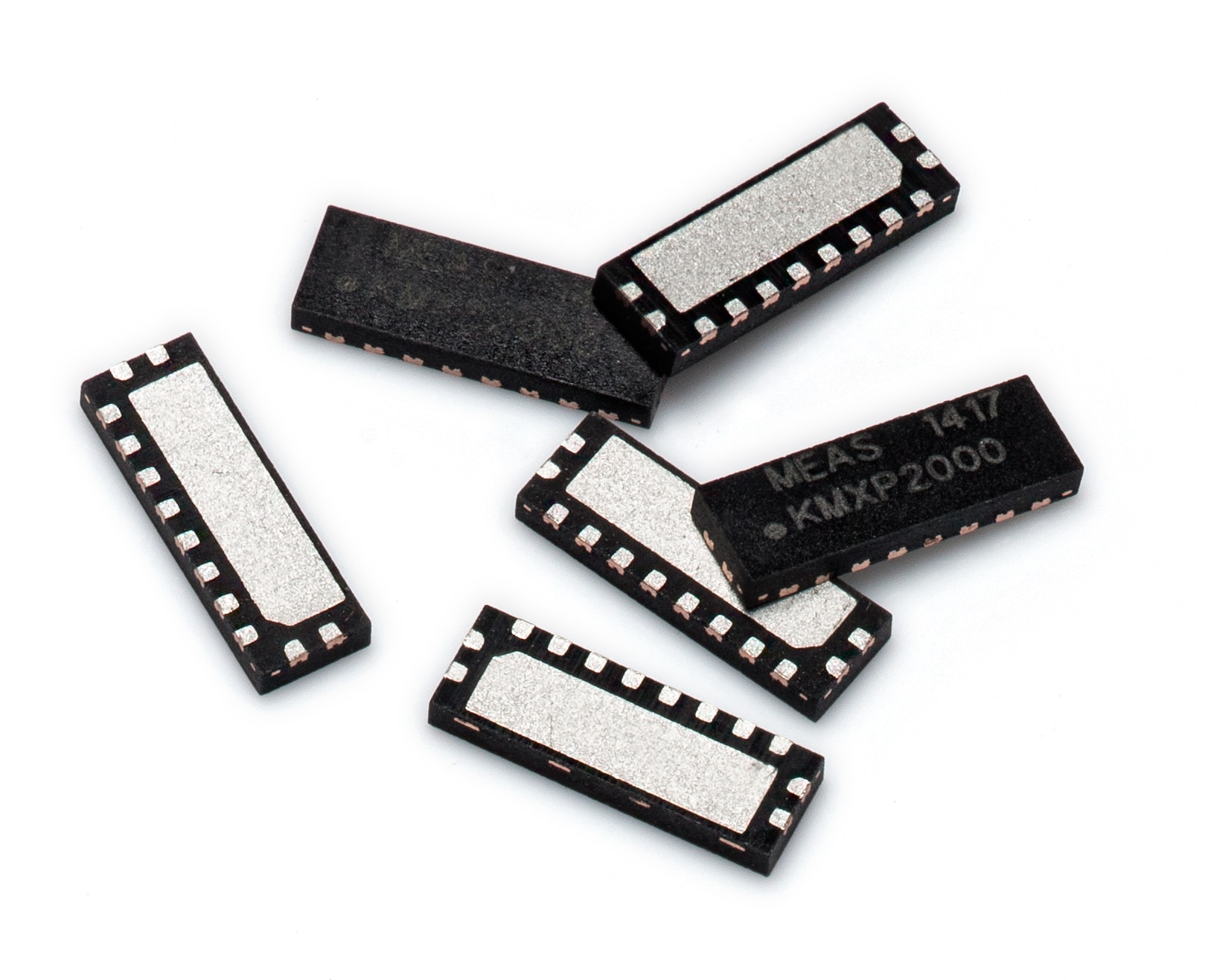

SMT TECHNOLOGY

According to the American Hospital Association, over 5,000 US registered hospitals experienced over 35 million admissions in 2017. While the medical industry in the US is pivoting to reduce hospital visits, admissions, and admission times, the demand to support the patient and the need for monitoring equipment remains consistent. Therefore, designing sensors for scalable, automated production has become a more desired option in the medical space to keep up with demand. Surface mount technology for sensors enables design engineers to embed the sensor within the electronics of the assembly. Photo optic sensors offer traditional lead-frame designs which are hand soldered into assemblies and are now packaged for SMT designs. The reflow solderable packaging allows engineers to design sensors into assemblies that are embedded through pick and place machines, increasing overall quality while reducing manufacturing time and cost. With the flexibility to be mounted vertically or horizontally, AMR sensors are designed for SMT packages, as well. Depending on the design of the system, this can play an important role to ensure the sensor can fit within the system and give more flexibility on the magnet placement.