MAGNETORESISTIVE SENSOR FAQS

SENSOR CHARACTERISTICS

What is the difference between low-field sensitivity and high-field sensitivity?

Magnetic sensitivity refers to a sensor’s ability to detect changes in magnetic field strength. It is a critical characteristic for MR sensors, determining how effectively they can measure variations in magnetic fields.

- Low-field sensitivity: Sensors with high sensitivity to weak magnetic fields can detect minute changes, making them suitable for applications requiring precise measurements in low-field environments, such as medical imaging or geophysical surveys.

- High-field sensitivity: Sensors designed for high-field sensitivity can accurately measure strong magnetic fields without saturation. These sensors are suitable for applications involving powerful magnets or high-current environments, such as industrial automation or automotive systems.

What is a pole pitch?

Pole pitch is a crucial measurement that refers to the distance between adjacent magnetic poles on a magnetized surface or within a magnetic field. It affects the sensor’s ability to accurately detect and measure magnetic field variations.

- A small pole pitch is suited for applications that require high resolution position sensing like robotics and industrial automation. Medical diagnostic equipment employs small pole pitches to improve resolution and accuracy.

- A medium pole pitch provides a balance between resolution and range suitable for dynamic environments such as automobiles and consumer electronics.

- A large pole pitch allows detection of magnetic fields over larger areas for applications in large-scale industrial equipment and renewable energy systems.

What are the characteristics of magnetic field strength?

Field strength characteristics vary across weak, medium, and strong magnetic fields. Here are the relevant criteria for each:

- Weak field strength: MR sensors require high sensitivity to detect minute changes in weak magnetic fields, often achieved through advanced thin-film processing technology for accurate measurements. Their temperature stability confirms that performance does not fluctuate with changes in temperature, which is crucial for maintaining precise measurements in low-field conditions.

- Medium field strength: Sensors operating in medium field strengths balance sensitivity and range. They confirm the sensor's output accurately reflects magnetic field variations through linearity and minimize hysteresis to maintain measurement accuracy.

- Strong field strength: MR sensors handle high field strengths without saturation. They enable reliable performance through range and temperature stability, maintaining linearity and minimizing hysteresis for consistent and accurate readings.

How does a switching field equal a magnetic field at switching voltage?

In the context of magnetoresistive (MR) sensors, the specific magnetic field strength required to change the sensor's resistance state is known as the switching field. When this field is applied, the sensor alters its electrical resistance, which we detect as a change in voltage (switching voltage). Essentially, the switching field triggers the sensor to switch its resistance state, and the switching voltage indicates this change.

What is the purpose of an air gap in magnetic sensors?

Air gap in the context of MR sensors, is the distance between the sensor and the magnetic source. This gap has a critical impact on the sensor’s performance and accuracy. Proper management of the air gap enables consistent, reliable results.

- Maximum air gap is determined through magnetic simulations, empirical testing and manufacturer specifications:

- Magnetic simulations: Software like Ansys Maxwell or MATLAB can model the sensor system to help predict the magnetic field strength at various air gaps.

- Empirical testing: Engineers carry out physical tests to validate the computer model and identify the space at which the sensor meets its minimum performance goals.

- Manufacturer specifications: Sensor manufacturers often provide guidelines on the maximum air gap based on the sensor’s design, intended application and their own laboratory tests.

- Sensor accuracy optimization requires maintaining an air gap within the sensor manufacturer’s specified range. This enables sufficient magnetic field strength for accurate measurements while minimizing noise and errors:

- Magnetic field strength: A smaller air gap results in a stronger magnetic field at the sensor which leads to higher sensitivity and accuracy. The magnetic field decreases as the gap increases, reducing sensitivity and accuracy.

- Signal to Noise Ratio (SNR): Higher magnetic field strength from smaller air gaps enhances the sensor’s ability to distinguish between the signal and noise. A larger gap makes it harder to accurately detect changes in the magnetic field.

- Measurement errors: Smaller air gaps minimize measurement errors leading to precise readings. Increased air gaps can introduce errors due to weaker magnetic fields and potential misalignment.

- Interrelationship between pole length, pole pitch and air gap: The pole length and pole pitch must be designed to work within the optimal air gap range specified by the sensor manufacturer. For example, sensors with a shorter pole length and smaller pole pitch can allow for a smaller air gap, improving sensor accuracy.

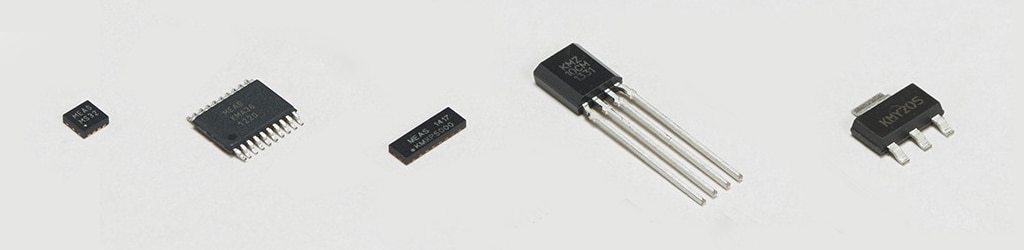

What is wafer level packaging?

Wafer level packaging (WLP) integrates fabrication, packaging, testing and burn-in of hundreds or thousands of sensors on a thin slice of semiconductor material (called a wafer) before it is divided into individual sensors.

Key benefits:

- Miniaturization: WLP facilitates smaller, more compact sensor designs, which are critical for applications with limited space constraints.

- Improved Performance: Wafer level packaging enhances electrical performance by shortening interconnects, thereby mitigating parasitic effects of inductance and capacitance.

- Cost Effectiveness: By increasing manufacturing scale and reducing the handling of individual sensors significantly reduces the cost when manufactured by WLP.

- Reliability: Reductions in processing and handling improve the quality and reliability of sensors by providing better protection from environmental factors.

Typical Applications:

- Consumer electronics

- Advanced automotive driver-assistance systems (ADAS)

- Medical diagnostic equipment

How does an AMR sensor determine the angle of rotation of an object?

An AMR sensor detects the direction of the magnetic field to determine an object's angle of rotation. When a permanent magnet rotates, the sensor detects changes in resistance due to the anisotropic magnetoresistance effect. Using a Wheatstone bridge configuration, the sensor converts resistance changes into differential sine and cosine signals. A computer algorithm processes these signals to determine the precise angle of rotation. Proper calibration is essential to enable accurate angle measurements, involving corrections for errors in offset, amplitude, and orthogonality. AMR sensors can measure angles up to 180° with accuracy between 0.5° and 0.1°. However, by combining AMR sensing with Hall-effect latches, they can achieve angle measurements through 360°.

WHEATSTONE BRIDGE CONFIGURATION

How do Wheatstone bridges improve the performance of AMR sensors?

AMR sensors typically employ resistive elements arranged in a Wheatstone bridge configuration to detect changes in resistance due to the anisotropic magnetoresistance effect. The bridge produces differential sine and cosine signals corresponding to the magnetic field direction. Computer algorithms process these signals to determine the precise position of the object. Multiple Wheatstone bridges are often employed to improve the accuracy and resolution of AMR sensors.

Functionality:

- Multiple Wheatstone bridges are configured in parallel to operate independently. These bridges provide redundant data to enhance accuracy and reliability.

- Algorithms process the redundant signals employing weighted averaging or advanced data fusion.

Benefits:

- Enhanced accuracy: Using multiple Wheatstone bridges can improve measurement accuracy by analyzing redundant signals and identifying erroneous readings.

- Higher resolution: Multiple bridges can also increase the resolution of the sensor, allowing for finer detection of magnetic field changes.

- Robustness: The use of multiple bridges can enhance the robustness of the sensor, making it more reliable in varying environmental conditions.

Applications:

- Vehicle detection: AMR sensors with multiple Wheatstone bridges are used in vehicle detection systems to accurately measure speed, direction, and presence of vehicles

- Angle measurement: In applications like motor control and robotics, multiple bridges help achieve precise angle measurements

HOMOGENOUS FIELD SENSING

What is homogenous field sensing?

Homogenous field sensing refers to the detection of magnetic fields that are uniform in strength and direction across area being sensed. Magnetoresistive sensors are intended to measure changes in magnetic fields accurately and consistently. There are cases where homogenous field sensing is critical and others in which it is not as important.

Critical applications for homogenous field sensing include:

MRI machine

In Magnetic Resonance Imaging (MRI) machines, a highly homogeneous magnetic field is crucial for producing clear and accurate images of the body's internal structures. Any inhomogeneity can lead to distortions and artifacts in the images.

Magnetic Navigation System

Magnetic Navigation Systems are used in aerospace and marine navigation. These systems rely on homogeneous magnetic fields to provide precise directional information. Variations in the magnetic field could lead to navigational errors.

Scientific Research

Experiments in physics and materials science often require homogeneous magnetic fields to confirm that the results are not influenced by field variations.

HYSTERESIS IN MAGNORESISTIVE SENSORS

How does hysteresis impact the accuracy of MR sensors?

Hysteresis refers to the lag between the input and output in a system, particularly when the magnetic field changes direction. In MR sensors, hysteresis can impact sensor accuracy in several ways:

- Residual Magnetization

- Effect: Hysteresis causes the sensor to retain some residual magnetization even after the magnetic field is removed or changed. This residual magnetization can lead to errors in subsequent measurements.

- Example: If an MR sensor is used to measure a magnetic field that changes direction, the residual magnetization from the previous field direction can cause the sensor to provide inaccurate readings.

- Lag in Response

- Effect: Hysteresis introduces a lag between the input magnetic field and the sensor's output. This lag can result in delayed or inaccurate measurements, especially in dynamic applications where the magnetic field changes rapidly.

- Example: In applications like vehicle detection, where the magnetic field changes quickly as vehicles pass by, hysteresis can cause the sensor to miss or inaccurately measure these changes.

- Offset Errors

- Effect: Hysteresis can cause offset errors, where the sensor's output does not return to zero when the magnetic field is removed. This offset can lead to a constant error in all subsequent measurements.

- Example: In angle measurement applications, an offset error due to hysteresis can cause the sensor to consistently report an incorrect angle.

Mitigation Techniques:

- Calibration: Regular calibration can help correct for hysteresis-induced errors by adjusting the sensor's output to account for residual magnetization and offset errors.

- Compensation Algorithms: Advanced algorithms can be used to compensate for hysteresis by modeling and correcting the sensor's response based on its magnetic history.

COMPARISONS

What is the difference between an AMR sensor and a GMR sensor?

Anisotropic magnetoresistive (AMR) and giant magnetoresistive (GMR) sensors both detect changes in magnetic fields by associated changes in thin film electrical resistance. They are also used in similar applications. However, there are differences in operating principles and key performance characteristics:

| Detection Principle | |

|---|---|

| AMR sensors measure changes in electrical resistance due to the angle between the magnetization and the current direction in a ferromagnetic material. This effect occurs because the resistance varies with the direction of the magnetic field relative to the current flow. | GMR sensors rely on the change in resistance caused by the alignment of magnetizations in multilayered ferromagnetic structures separated by non-magnetic layers. When the magnetic layers are aligned parallel, the resistance is lower; when they are antiparallel, the resistance is higher. |

| Sensitivity | |

|---|---|

| Generally, AMR sensors offer moderate sensitivity, making them suitable for applications where precise but not extremely high sensitivity is required. |

GMR sensors provide higher sensitivity compared to AMR sensors, allowing them to detect very small changes in magnetic fields. This makes them suitable for applications requiring high precision. |

| Structure | |

|---|---|

| Typically, AMR sensors consist of a single layer of ferromagnetic material, such as permalloy (nickel-iron alloy). | GMR sensors are composed of multiple layers, including ferromagnetic layers, such as cobalt, and non-magnetic layers, such as copper. This multilayer structure is key to achieving the giant magnetoresistance effect. |

| Performance Characteristics | |

|---|---|

| AMR sensors are known for their simplicity and cost-effectiveness, with a narrow detection range and a small hysteresis. | GMR sensors offer a wider detection range and higher reliability, though they may exhibit multiple switching points in the presence of strong permanent magnets. |

What is the difference between an AMR sensor and a Hall effect sensor?

Anisotropic magnetoresistance (AMR) sensors and Hall effect sensors both detect magnetic fields but operate differently and have distinct characteristics:

| Operating Principle | |

|---|---|

| AMR sensors detect changes in electrical resistance due to the angle between the magnetization and the current direction in a ferromagnetic material. | Hall effect sensors measure the voltage generated perpendicular to the current flow when exposed to a magnetic field. |

| Sensitivity |

|---|

| AMR sensors generally offer higher sensitivity compared to Hall effect sensors, making them suitable for detecting minute changes in magnetic fields. |

| Magnetic Field Orientation | |

|---|---|

| AMR sensors respond to magnetic fields parallel to the sensor. | Hall effect sensors respond to fields perpendicular to the sensor. |

| Design Flexibility | |

|---|---|

| AMR sensors provide more design flexibility due to their ability to detect horizontal magnetic fields. | Hall effect sensors typically require the magnet to be placed directly above the sensor. |