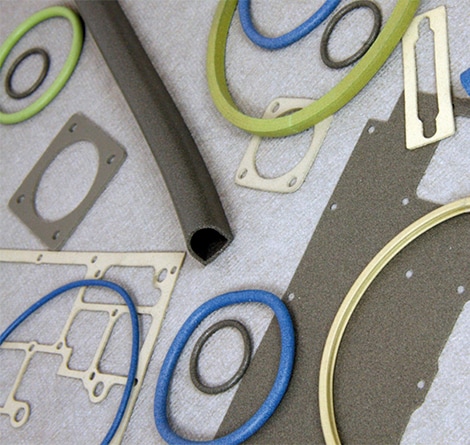

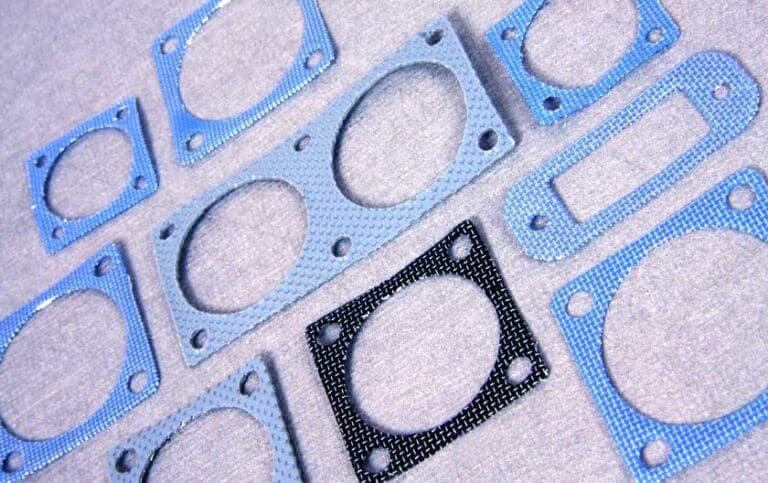

Knitted wire mesh gasket

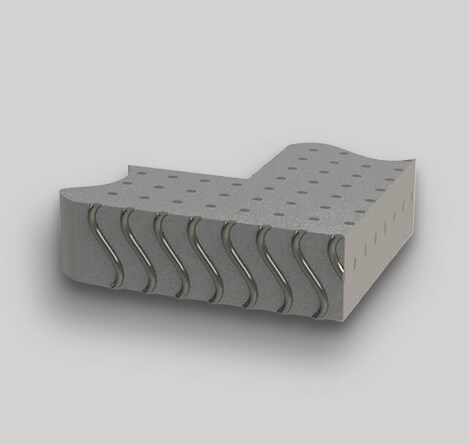

A range of knitted wire mesh gaskets, providing a cost-effective solution to high shielding performance applications in the magnetic and electrical fields RFI/EMI and including EMP. The mono-filament interlocking-loop construction gives strength while allowing it to conform to almost any size or shape. The manufacturing process allows for an optional elastomer core to be included into the product to aid compression.

Features & Benefits

- The mono-filament interlocking loop construction gives strength while allowing it to confirm to almost any size or shape.

- Excellent radio frequency interference (RFI)/electromagnetic interference (EMI) shield between two metallic surfaces.

- Delivers good galvanic match with mating flanges, thereby limiting the possibility of corrosion between gasket and flange.

- A selection of elastomer cores are available to meet conditions such as temperature range, compression set, compression force.

Design Considerations

Consideration should be given to the termination of cut mesh ends. Sometimes loose wires are evident after cutting. If you choose to cut the mesh yourself loose wires can be avoided by:

- Dipping the end in glue.

- Spot welding the cut end.

- Sewing the cut end.

- Sufficient compression forces are required to achieve good contact. Contact seal between the metalwork.

- Galvanic compatibility can be achieved by choosing a suitable wire type.

- Water and moisture sealing is not possible with this product. However it does offer a limited dust seal.

- Solid knitted wire mesh suffers from compression set. So it is not recommended for frequent opening of panels.

EMI Shielding Engineering and Technical Resource Hub

Welcome to the resource hub for our advanced performance materials portfolio, featuring cutting-edge solutions in EMI shielding. Whether you're seeking to enhance electrical insulation, environmental protection, or electromagnetic interference mitigation, our comprehensive collection of whitepapers, brochures, videos, and solution guides is designed to support engineers, designers, and decision-makers across industries. Dive into our expertly curated content to discover how our innovative materials can elevate your applications with reliability, efficiency, and precision.

Features

Knitted Wire Mesh Featured Products

Electromagnetic Interference Shielding Whitepaper

Electromagnetic interference (EMI), also known as radio frequency interference (RFI), results when an outside source causes noise or interference in an electrical path or circuit. Shielding is necessary to prevent EMI from causing electronic devices to malfunction.

Download NowKemtron Ltd., now part of TE Connectivity Extended product portfolio

Contact information

United Kingdom

Phone: +44 (0) 1376 348115

Email : info.braintree@te.com

France

Phone: + 33 (0) 160778316

Email : info.braintree@te.com

Germany

Phone: +44 (0) 1376348115

Email: info.braintree@te.com

Rest of Europe

Phone: +44 (0) 1376348115

Email: info.braintree@te.com

Asia

Phone: +44 (0) 1376348115

Email : info.braintree@te.com